Broiler Lighting Management with LED Chicken Coop Lights

Scientific poultry lighting management is one of the most important factors in modern broiler production. Using the right LED chicken coop light not only supports maximum growth performance and feed efficiency but also improves animal welfare. This guide explains evidence-based lighting protocols designed around broiler physiological stages, spectral sensitivity, and behavioral needs.

1.1 Broiler Development Phases

Successful broiler production begins with understanding how lighting needs change across different growth phases.

Brooding Phase (0–2 Weeks): This foundational stage is critical for establishing a robust immune system and promoting healthy skeletal development. Proper environmental conditions, including lighting, ensure chicks develop resilience and a strong physical framework for later growth.

Growing-Finishing Phase (3 Weeks to Market Age): During this phase, the focus shifts to maximizing muscle development and achieving optimal weight gain to prepare broilers for market. Lighting plays a pivotal role in supporting efficient growth and overall health.

With proper use of LED chicken coop lights, farmers can support both early immune development and later muscle growth effectively.

1.2 Optimal Light Spectrum for Broiler Performance

Light spectrum plays a decisive role in broiler metabolism, behavior, and overall performance.

Wavelength Range: 415–560 nm (blue to green spectrum).

Scientific Benefits: Research shows that LED chicken coop lights emitting blue-green wavelengths can enhance growth rates by 7–12% and improve the feed conversion ratio (FCR) by 3–5%. These wavelengths stimulate metabolic processes, leading to better nutrient absorption and faster weight gain. Additionally, blue-green light promotes calmness, reducing stress-related behaviors like feather pecking.

Practical Implementation: Install energy-efficient LED chicken coop lights designed to emit light within the 415–560 nm range. These lights optimize broiler health while minimizing energy costs, making them a sustainable choice for poultry farmers. For best results, ensure lights are evenly distributed to avoid shadowing and maintain consistent exposure.

By adopting LED chicken coop lights within the 415–560 nm range, farmers can achieve healthier flocks and greater production efficiency.

1.3 Illuminance Requirements for Optimal Growth

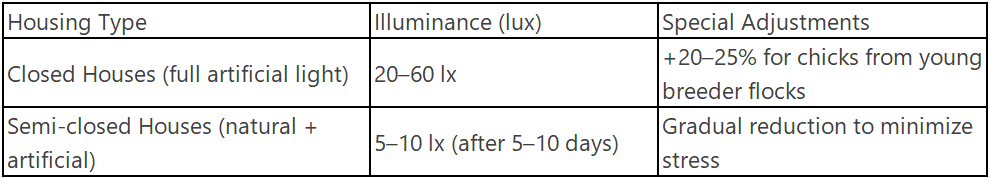

The intensity and balance of LED chicken coop light directly influence feeding behavior, activity levels, and stress reduction in broilers.

Balanced Lighting Levels: Providing appropriate illuminance at each growth stage is essential for uniform development and stress reduction. During the brooding phase, softer lighting (e.g., 20–50 lux) supports chick comfort and encourages early feeding. In the growing-finishing phase, slightly higher illuminance (e.g., 10–20 lux) promotes activity and efficient growth without causing agitation.

Additional Considerations: Use dimmable LED chicken coop lights to adjust intensity based on the birds' age and behavioral needs. Consistent lighting schedules (e.g., 18–20 hours of light per day) paired with adequate darkness periods enhance circadian rhythms, further reducing stress and improving overall flock health.

Proper illuminance control with LED systems provides healthier flocks, improved feed conversion, and a calmer barn environment.

1.4 Illuminance Guideline

The correct illuminance level of LED chicken coop lights is crucial for maintaining bird comfort and achieving consistent growth. During the brooding stage (0–1 weeks), softer light levels of around 20–30 lux encourage chicks to locate feed and water easily while minimizing stress. As broilers transition to the growing-finishing stage (3 weeks to market age), illuminance can be gradually reduced to 10–20 lux, which helps control activity, reduce aggressive behaviors, and support efficient weight gain.

Using dimmable LED chicken coop lights allows farmers to fine-tune light intensity for each growth stage, ensuring uniform development while lowering energy consumption.

1.5 Photoperiod Strategy

Lighting schedules—or photoperiods—directly affect feeding, rest, and growth patterns in broilers. A balanced cycle typically includes 18–20 hours of light paired with 4–6 hours of darkness per day, helping to synchronize circadian rhythms and enhance welfare.

For young chicks, extended light periods support feeding and early growth. As broilers mature, slightly longer dark phases promote natural rest and reduce stress, while still maintaining consistent feed intake. Seasonal variations should also be considered; for example, in winter, artificial lighting can compensate for reduced daylight hours.

A structured photoperiod with LED chicken coop lights maximizes feed efficiency, stabilizes behavior, and prepares broilers for uniform market readiness.

1.6 Intelligent Lighting Parameters

Modern poultry farms increasingly adopt intelligent lighting systems to improve efficiency and precision. Advanced LED chicken coop lights can be programmed to simulate natural sunrise and sunset, reducing sudden light changes that may startle birds. Automated dimming and scheduling features also allow farmers to adjust lighting intensity and duration with accuracy, ensuring each stage of development receives the optimal environment.

Additionally, smart controls help reduce power consumption and maintenance costs while improving overall flock health. Integration with sensors and monitoring tools enables data-driven decisions, ensuring lighting conditions align with both animal welfare standards and production goals.

Intelligent LED lighting systems offer farmers a sustainable, automated solution that supports flock well-being, reduces operational costs, and drives long-term productivity.

.jpg)

1.6 Energy Efficiency and Cost Benefits

Beyond animal welfare, lighting technology also impacts long-term energy use and operational costs.

Why Choose LEDs: LED chicken coop lights are highly energy-efficient, consuming up to 80% less power than traditional incandescent or fluorescent bulbs. Their durability (lasting up to 50,000 hours) reduces replacement costs, and their low heat output minimizes ventilation expenses.

Economic Impact: By optimizing growth rates and feed efficiency, LED lighting can increase profitability. For example, a 5% improvement in FCR can significantly lower feed costs, which account for 60–70% of poultry production expenses.

Investing in durable LED chicken coop lights helps poultry producers lower expenses while maintaining consistent, high-quality performance.

1.7 Practical Tips for Implementation

Applying the right lighting strategy requires careful installation, ongoing maintenance, and observation.

Installation: Position LED chicken coop lights to ensure uniform coverage across the coop, avoiding dark spots that could disrupt flock behavior.

Maintenance: Regularly clean fixtures to prevent dust buildup, which can reduce light output and efficacy.

Monitoring: Observe broiler behavior to fine-tune light intensity and duration, ensuring the flock remains active but not stressed.

By leveraging the benefits of LED chicken coop lights tailored to the specific needs of broiler development stages, poultry farmers can enhance productivity, improve animal welfare, and achieve greater operational efficiency.

Related Product

Poultry Lighting Bulbs D80

Related Blog

Intelligent Led Broiler Lighting System

Broiler Lighting: Best Light for Chicken Brooder

Led Poultry House Lighting: Effect of Light on Broiler Production