How Poultry Lighting Affects Production and Growth?

Directory:

1. Why Poultry Lights Are Essential for Modern Farms?

2. Key Parameters of Poultry Lighting Explained

3. From “Traditional Lamps” to “Smart Lighting”

4. Tailored Lighting Plans for Different Poultry Types

5. Common Problems in Poultry Lights and Solutions

6. Smart & Green Future of Poultry LED Lighting

7. Conclusion: Poultry Lights as a High-Return Investment

1. Why Poultry Lights Are Essential for Modern Farms?

People usually have a common misconception that the lights installed in poultry farms are for the convenience of the staff during operation. In reality, poultry lighting directly affects bird biology.

Chickens and other poultry perceive a broader light spectrum than humans, including ultraviolet, and their growth and reproduction are closely tied to light signals. The duration, intensity, and spectrum of light influence hormone release through the hypothalamus–pituitary–gonadal axis, which regulates egg production, growth, and fertility.

In closed or large-scale poultry houses, natural daylight is either inconsistent or completely absent. Without proper artificial lighting, layers may show reduced laying rates, broilers may grow unevenly, and breeders can suffer from poor fertility. Effective lighting is therefore not optional—it is a critical management tool that ensures higher production, stable flock behavior, and better feed efficiency.

2. Key Parameters of Poultry Lighting Explained

Lighting in poultry houses is not just about turning the lamps on and off. Four technical factors—photoperiod, intensity, spectrum, and rhythm—work together to shape bird growth, behavior, and productivity.

Below we break them down in simple terms, highlighting the different needs of laying hens, broilers, and breeders.

2.1 Photoperiod – “How long should the lights stay on?”

The length of daily light exposure directly controls a bird’s growth and reproductive cycle. Farmers must tailor schedules by species and growth stage:

(1) Laying hens:

Laying phase: Require 14–16 hours of continuous light (e.g., 16L:8D). If light falls below 12 hours (as in winter), hens receive a “stop-laying” signal.

Chick rearing (0–6 weeks): Light is gradually reduced from 24 hours to 8–10 hours. This prevents hens from maturing too early.

(2) Broilers (meat chickens):

Need 18–22 hours of light throughout life. Long days extend feeding time, driving weight gain. However, at least 2–4 hours of darkness is critical for rest and stress reduction.

(3) Breeders:

Light schedules should mimic natural seasonal changes. Gradually lengthening daylength improves fertility and egg set rates.

Common mistake: Assuming “longer is always better.” For example, giving 20+ hours of light to layers actually stresses hens, reduces fertility, and lowers egg production.

2.2 Light Intensity – “How bright should it be?”

Light intensity is measured in Lux (1 Lux ≈ brightness of an overcast indoor room). Different stages and poultry types demand different levels:

(1) Brooding (0–2 weeks): 20–30 Lux. Bright light helps chicks find feed and water quickly, lowering early mortality.

(2) Laying hens (production stage): 10–20 Lux. If too strong (>30 Lux), hens become restless and develop harmful behaviors like feather pecking. Too dim (<5 Lux) reduces feed intake and egg yield.

(3) Broilers (fattening phase): 5–10 Lux. Lower brightness keeps birds calmer, reduces energy waste on movement, and supports rapid weight gain.

Practical tip: Light must be evenly distributed across the house. Avoid dark corners (<3 Lux) or hot spots. Adjust hanging height (2–3 m above ground) and lamp spacing (every 2–3 m) for balance.

2.3 Spectral Content – “Which colors matter most?”

In recent years, poultry lighting research has focused on spectrum optimization, challenging the old belief that “any white light will do.”

Traditional incandescent lamps lean toward warm light (red-dominant), while fluorescent lamps lean toward cool light (blue-dominant). However, both have limited spectral ranges and cannot precisely meet poultry needs.

In contrast, LED spectra can be customized, with each wavelength playing a different role:

l red light (620–660 nm) promotes egg production in layers and accelerates weight gain in broilers;

l blue light (450–495 nm) suppresses broiler activity but may cause stress;

l green light (520–560 nm) can help increase egg weight;

l UV-A (320–400 nm) supports vitamin D3 synthesis but requires careful control.

In practice, mixed light dominated by red wavelengths is recommended for layer houses, while broiler houses should prioritize warm red light with reduced blue content.

2.4 Light Rhythm – “Continuous or intermittent?”

Lighting schedules can be continuous or broken into cycles:

(1) Continuous lighting:

Example:

16 hours straight. Simple, but high energy consumption and greater bird fatigue.

(2) Intermittent lighting:

Example:

Layers: 2 hours light / 2 hours dark (repeating).

Broilers: 1 hour light / 3 hours dark (repeating).

Benefits of intermittent rhythm:

Saves 30–50% energy.

Gives birds more rest, lowering stress and aggression.

Research shows laying rates can improve slightly compared with continuous light.

Important note: Rhythms must remain consistent. Frequent changes disrupt circadian rhythm, stressing the flock.

In short:

When applied correctly, these parameters transform lighting from a utility into a powerful tool for poultry performance.

3. From “Traditional Lamps” to “Smart Lighting”

Lighting technology in poultry farming has changed dramatically over the past few decades. Each stage brought progress, but also limitations that explain why farms are now moving toward LED and smart systems.

Incandescent lamps were once the standard. Their spectrum is close to natural sunlight and the upfront cost is low. However, they waste most energy as heat, last only about 1,000 hours, and are unsuitable for modern large-scale houses. They remain practical only for small backyard or temporary setups.

Fluorescent lamps reduced energy use compared to incandescent and provided stronger brightness. Yet, they rely on fixed spectral output, contain mercury, and typically last around 8,000 hours. Many mid-sized farms adopted them during the transition era, but environmental concerns and limited spectral control restrict their value today.

LED lights have become the mainstream choice. They cut energy consumption by up to 70%, operate over 50,000 hours, and allow tailored spectral design for broilers, layers, or breeders. They are also mercury-free and environmentally friendly. While the initial cost is higher, the long-term performance and efficiency make LEDs the most cost-effective option for intensive poultry houses.

The latest step is smart LED systems. Beyond efficiency, they enable remote control via apps or central management software, automatic scheduling of photoperiods, and integration with climate sensors for temperature and humidity. These systems adjust lighting programs dynamically, ensuring optimal growth and reproduction with minimal manual intervention. Their upfront cost and need for professional setup are higher, but for modern farms aiming at precision management, smart lighting delivers unmatched benefits.

4. Tailored Lighting Plans for Different Poultry Types

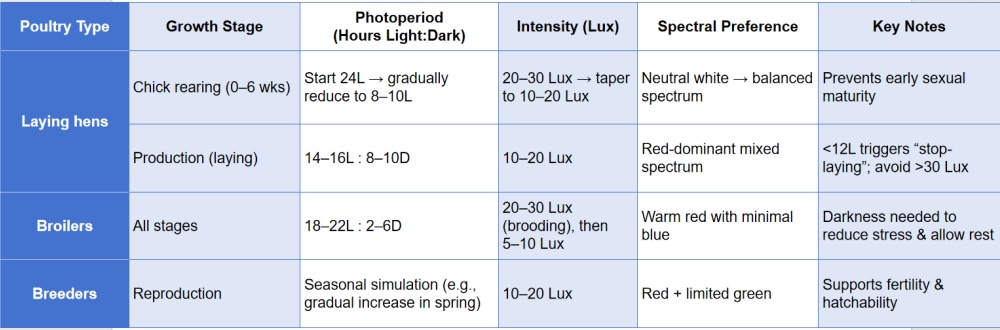

Lighting strategies should never be “one size fits all.” Different poultry categories respond uniquely to light, so farmers must adapt programs for layers, broilers, and breeders.

(1) Laying hens (layers)

Photoperiod: 16 hours of light during production (e.g., 5:00–21:00) and 8 hours in the resting phase.

Intensity: 15 Lux evenly across the house; avoid shadowed corners below 10 Lux.

Spectrum: Red-to-blue ratio of 3:1 (around 660 nm red + 450 nm blue), with limited UV-A exposure (1–2 hours daily) to improve calcium absorption and shell strength.

Rhythm: Intermittent cycles (2 h light + 2 h dark) help conserve energy while reducing stress behaviors.

(2) Broilers (meat birds)

Photoperiod: 24 h light in the brooding phase (0–2 weeks), then 20 h light + 4 h dark from week 3 onward (e.g., 6:00–2:00).

Intensity: 25 Lux during brooding to encourage feeding and drinking; reduce to 8 Lux in the grow-out phase to limit activity and improve feed conversion.

Spectrum: Dominantly red (≈70% at 660 nm) with minimal blue (<10%) to minimize stress.

Rhythm: Continuous light early, then switch to intermittent cycles (1 h light + 3 h dark) to balance growth and rest.

(3) Breeders

Photoperiod: Seasonal simulation—gradually extend daylight hours from 12 to 16 as in spring.

Intensity: 15–20 Lux, strong enough to support activity but not excessive, which could disrupt mating.

Spectrum: Broad-spectrum lighting (red, green, blue) to mimic natural daylight and stimulate breeding behaviors.

Rhythm: Continuous light during the active phase to maintain consistent mating patterns.

When applied correctly, these tailored lighting programs improve performance, welfare, and efficiency across all poultry houses.

5. Common Problems in Poultry Lights and Solutions

Even with well-planned programs, lighting issues often appear in daily farm management. Below are the most frequent problems and actionable solutions.

Problem 1: Uneven light distribution

Cause: Lamps hung too high, wide spacing between fixtures, or insufficient lamp power.

Solution: Use a staggered hanging pattern instead of straight lines. Choose wide-angle LED lamps (≥120° beam angle). Add supplemental lights in corners to eliminate dark spots.

Problem 2: Sudden drop in egg production (excluding disease)

Possible causes: Shortened photoperiod due to timer failure, reduced light intensity from faulty lamps, or abrupt spectral changes after replacing bulbs.

Solution: Check timers and fixtures weekly. When replacing lights, phase in the new lamps over 1 week before a full switch. Keep photoperiod, intensity, and spectrum stable unless deliberately adjusted for growth stage.

Problem 3: Feather pecking or cannibalism in broilers

Causes: Excessive brightness (>10 Lux), too much blue light, or insufficient dark periods.

Solution: Reduce light intensity to 5–8 Lux. Shift spectrum toward red while reducing blue. Guarantee at least 4 continuous dark hours daily for rest.

Problem 4: High lighting costs

Solution: Upgrade to LED lamps to save up to 70% energy. Apply intermittent lighting cycles to reduce operating hours. Install smart controllers that adjust brightness automatically with daylight, lowering artificial light use during sunny hours.

6. Smart & Green Future of Poultry LED Lighting

The future of poultry lighting is moving beyond simple illumination. For large-scale farms, the next decade will be defined by smart integration and sustainable design.

6.1 Smart upgrades

Light–climate–feed integration: Smart systems will connect lighting with temperature, humidity, and feed intake data. For example, during heat stress, the system can automatically dim lights to reduce metabolic load.

Targeted lighting: With cameras and sensors, farms may provide individualized light programs. Weak or sick birds could receive longer photoperiods to encourage feeding, while the rest of the flock follows standard cycles.

Data-driven management: Systems will log photoperiods, intensity, and production metrics like egg count or weight gain. AI analysis will then suggest or automatically apply optimized lighting schedules tailored to each flock’s performance.

6.2 Green development

Energy efficiency: Research is pushing LED efficiency beyond 150 lumens per watt, cutting power costs further. Solar-assisted systems are likely to become viable for remote or off-grid farms.

Eco-friendly materials: Mercury-free, recyclable fixtures will become the industry standard, aligning with environmental regulations and farm sustainability goals.

Welfare-focused lighting: Welfare directives, especially in Europe, are driving adoption of sunrise–sunset simulation instead of abrupt on/off cycles. Such gradual transitions reduce stress and improve overall flock health.

As technology advances, poultry LED lighting will no longer be just about visibility—it will become a central tool for precision farming, sustainability, and animal welfare.

7. Conclusion: Poultry Lights as a High-Return Investment

For farmers, poultry lighting is not a background detail—it is a direct driver of production, welfare, and profitability. The right program can improve egg yield, shorten growth cycles, and reduce stress, while poor lighting undermines all of these.

Traditional lamps may seem affordable, but their high energy use, short lifespan, and limited control make them costly over time. By contrast, poultry LED lighting offers precise spectrum tuning, stable intensity, and smart automation that align with modern farm needs. It reduces electricity bills, lowers maintenance, and creates healthier conditions for layers, broilers, and breeders alike.

The path forward is clear: adopting poultry LED lighting is not just an upgrade—it is an investment in long-term performance, sustainability, and competitiveness. For farms aiming to maximize efficiency and prepare for future demands, switching to LED is the most practical and profitable decision today.

Related Product

FAQs

Q: Which light is better for broilers?

A: White light (full-spectrum LEDs) is optimal for broilers. It enhances feed intake, muscle growth, and weight gain by 8-10% compared to red light. White light also supports consistent feed conversion ratios (FCR of 1.6 vs. 1.8 under red light).

Q: Why does red light produce smaller eggs?

A: Red light may prematurely trigger oxytocin release, shortening yolk deposition time. This reduces egg weight after 30 weeks. Compensate by adding green light (5 lux) to nesting areas to improve calcium metabolism and shell quality.

Q: Does red light improve egg production in laying hens?

A: Yes, red light (660 nm) accelerates sexual maturity and increases egg quantity over long-term use (18–60 weeks) by stimulating reproductive hormones. However, eggs under red light are consistently smaller in weight compared to white or green light, especially after 30 weeks .

For egg quality, green light outperforms red light, producing thicker and stronger eggshells.

Q: How does red light affect chicken behavior?

A: Red light reduces stress due to its longer wavelength (660 nm), which minimally disrupts circadian rhythms. It promotes passive behaviors (resting, preening) and reduces aggression in flocks.

In contrast, blue light increases anxiety in poultry (e.g., panting, swarming in ducks), while white light maintains behavioral stability.