LED色温对比:3000K vs 4000K vs 5000K vs 6500K

目录

引言

选择错误的LED 色温并非无关紧要的技术细节——它会直接影响日常运营和长期投资回报率。

在商业办公室和仓库中,不合适的色温往往会导致生产力下降、眼睛疲劳加剧,并引发员工频繁投诉。在工业或户外环境中,不合适的色温会降低对比度和能见度,从而造成安全隐患。对于体育场馆而言,不合适的色温甚至可能导致转播问题,例如画面肤色不自然或过曝。

因此,选择色温时绝不能仅仅依据“看起来最亮”的标准。

本指南专为需要清晰实用答案的商业、工业、体育和户外照明决策者而设计。它不赘述定义,而是侧重于实际应用案例的比较——展示不同色温在特定应用中的表现。

本文通过决策导向的比较图表和基于场景的分析,帮助您快速确定最适合您环境的可靠色温,不仅在第一天如此,而且在多年的使用中也是如此。

终极色温对比图

下表并非旨在解释开尔文值是什么——它是为了帮助您更快、更安全地做出照明决策而建立的。

这张图表并非孤立地比较色温,而是将每个开尔文范围与实际空间中光线的感知和使用方式联系起来。它不仅突出了色温的优势,也强调了色温应用不当可能带来的风险。

要有效使用此图表,请关注的不仅仅是“K”值。还要考虑视觉感知、典型应用和长期可用性如何与您的项目目标相契合。

对比图表包括:

色温 (K)

视觉 感知

典型 应用

优点

顾问

误用风险

这种结构确保您不仅仅是在选择色温,而是在选择适合您特定环境的色温。

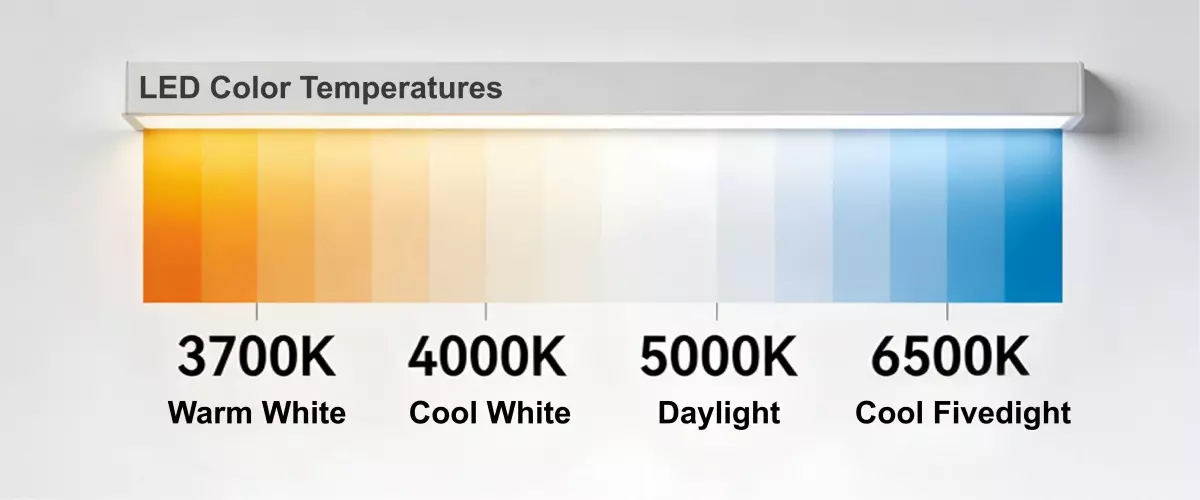

色温(K) | 视觉感知 | 典型应用 | 优点 | 缺点 | 误用风险 |

3000K(暖白光) | 温暖、柔和、带黄色的光线 | 接待区、餐厅、休息室、住宅区、装饰性户外空间 | 营造舒适放松的氛围;减少眩光;长时间停留也能保持视觉愉悦。 | 警觉性低;对比度差,难以完成精细任务 | 工作场所生产力下降;安全关键区域能见度不足 |

4000K(中性白) | 平衡的白色,自然色调 | 办公室、教室、零售空间、轻工业区 | 良好的视觉舒适度;有助于集中注意力而不疲劳;广泛认可的标准 | 与较高CCT相比,刺激性较低;不适合高精度任务。 | 在高强度活动或巡检环境中可能会感到枯燥乏味 |

5000K(日光白) | 清爽明亮,如同日光一般 | 仓库、工厂、体育设施、大型商业空间 | 增强对比度和可视性;提高任务准确性;有助于保持警觉 | 长时间停留时可能会感觉刺眼;眩光风险较高。 | 室内长时间使用会导致视觉疲劳和不适感。 |

6500K (冷日光) | 非常酷的蓝白色 | 户外安保区域、港口、高杆照明、以广播为主的体育场馆 | 最大可见度;强对比度;适合拍照的照明 | 对人眼来说最不舒服;外观不自然 | 眼睛疲劳;不适;不适合办公室或零售场所;过度照明问题 |

阅读更多:如果您想了解更多相关信息,这里有一篇博客,详细解释了什么是 LED 色温。。

按应用划分的详细色温比较

色温的选择绝不能孤立地看待。同样的开尔文值,在不同的场合和使用方式下,效果可能截然不同。

以下各节将通过实际应用场景而非抽象定义来比较常见的LED色温。每项比较都从实际决策情境出发——人们在空间中停留的时间、他们执行的任务以及随着时间的推移可能出现的视觉风险。

这些对比研究并非简单地将色温评为“好”或“坏”,而是解释了为什么某种色温在特定环境下比另一种效果更好。这种方法有助于照明规划人员和决策者选择能够兼顾生产力、舒适度、安全性和长期可用性的解决方案,而不仅仅是依赖亮度或外观。

3000K 与 4000K(商业及办公照明)

在商业和办公环境中,色温的决定应该从一个问题开始:人们在那里停留多久,以及他们在那里需要做什么。

对于员工长时间面对屏幕或处理精细工作的办公场所而言,视觉清晰度和注意力至关重要。在这种情况下,4000K 中性白光照明 能够营造平衡的视觉效果,帮助员工保持专注,而不会感到刺眼。它有助于提高工作效率,尤其适用于办公室、共享办公空间和会议室等需要长时间使用的场所。

相比之下,3000K暖白光 营造出更柔和、更轻松的氛围。虽然这可以提升视觉舒适度和情感上的温暖感,但长时间工作后可能会降低视觉敏锐度。不过,这种柔和的色调非常适合接待区、休息室和面向客户的空间,在这些地方,舒适度和氛围比工作效率更为重要。

实际上,许多商业项目都将两者结合起来。

4000K 通常用于主要工作区域,而 3000K 则用于以服务为导向或短期停留的区域,在这些区域,顾客的感知比持续警觉性更重要。

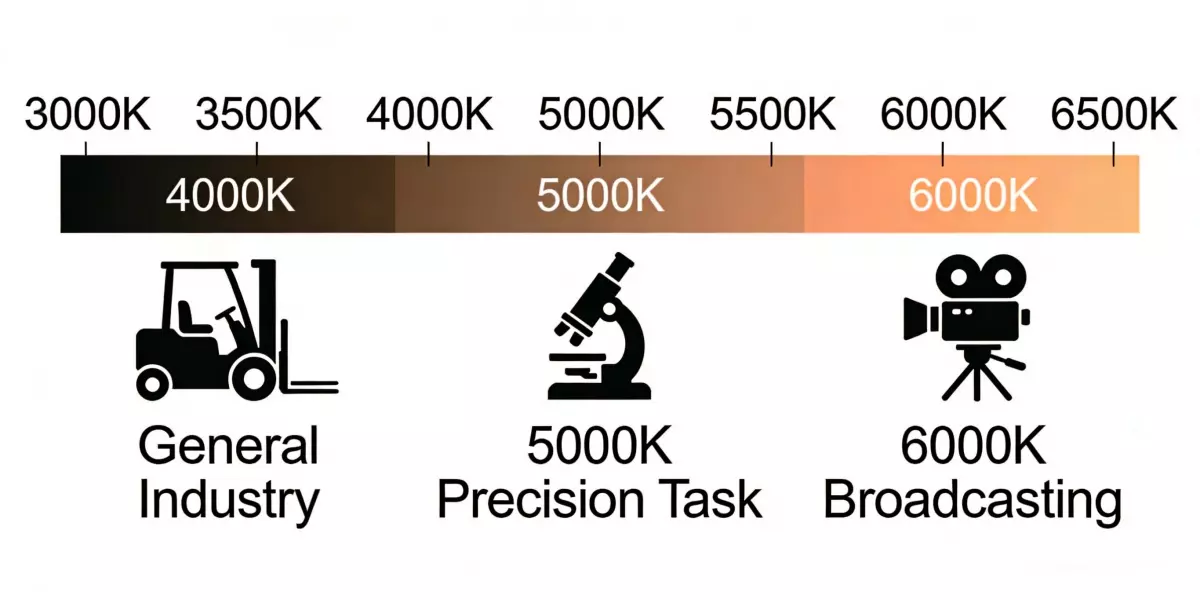

4000K 与 5000K(仓库及工业照明)

在仓库和工业设施中,选择错误的色温会造成极高的运营成本。这里的照明会影响安全性、准确性以及工人在长时间轮班中的耐力。

4000K 的照明 提供中性的视觉环境,可减少长时间工作造成的眼部疲劳。它使工作人员能够清晰地看到通道、设备和地面标记,而不会产生过多的眩光。对于实行多班制或通宵运营的场所,这种色温平衡通常可以提高舒适度和工作稳定性。

另一方面,5000K 照明可提供更高的视觉对比度和更清晰的细节。这在对检测精度、标签标注和精确操作要求极高的领域可能具有优势。然而,如果设计不当,在大面积空间或长时间使用时,可能会加剧视觉疲劳。

许多运营商采用分区方法——在一般流通和工作区域使用 4000K,而在检验线或质量控制区域选择性地使用 5000K。

如需更深入的技术分析,请参阅我们的4000K 与 5000K 仓库照明案例研究。

5000K 与 6500K(体育和高精度应用)

在体育场馆和高精度环境中,色温不仅影响可见度,还影响空间在摄像机中的呈现方式。

5000K 的色温通常接近自然日光,能够提供均衡的照明,与相机传感器完美匹配。它能保留肤色,减少过度曝光,并为现场直播和回放提供一致的视觉效果。因此,许多专业体育场馆都采用 5000K 至 5700K 的色温范围。

6500K 的灯光 对人眼来说看起来更亮,但会呈现出更冷、更蓝的色调。虽然这可以提高视觉清晰度,但也可能导致镜头出现眩光和色彩失真。在广播电视制作中,这通常会导致画面更加生硬,并增加后期处理的需求。

对于运动员和摄像机都很重要的环境来说,均衡的日光范围通常比单纯提高亮度更可靠。

5700K vs 6500K(户外安防监控)

在户外安防应用中,更亮的照明并不总是能带来更好的监控效果。关键因素是长期的视觉性能。

5700K 的照明色温 接近日光,能够提升人脸识别和物体识别的准确性,且不会产生过多眩光。它有助于安保人员长时间监控场所,从而减轻长时间轮班带来的视觉疲劳。

6500K 的照明虽然看起来更亮,但会在路面或车辆上造成强烈的对比度和反射眩光。随着时间的推移,这可能会降低监控精度并增加眼睛疲劳,尤其是在需要持续观察的停车场和周边区域。

对于大多数以安全为重点的项目而言,均衡的日光范围比最大表观亮度能提供更一致的结果。

为什么色温稳定性在实际应用中如此重要?

大多数色温对比只关注第一天的光线效果。但在实际项目中,这种方法往往行不通。

色温漂移是业内常见的难题。由于LED灯具在高功率和高热量下运行,传统的荧光粉材料(通常是荧光粉与硅的混合物)会随着时间推移而降解。这会导致色温偏移、亮度下降和视觉输出不一致。例如,一个5000K的灯具可能会逐渐显得偏冷或光线不均匀,从而破坏最初的照明设计,使任何最初的对比都失去意义。

根本原因在于散热和材料的限制。导热性差会导致热量滞留在光源周围,加速荧光粉老化并降低内部量子效率。在连续运行条件下,尤其是在工业、户外和高功率应用中,这种不稳定性将难以避免。

CeramicLite公司利用荧光透明陶瓷(FTC)LED芯片解决了这一难题。FTC材料是传统荧光粉系统的下一代替代品。它具有卓越的热稳定性、高透光率以及强大的耐腐蚀性和抗老化性。其内部量子效率超过98%,导热系数高达10 W/m·K,且在10万小时内光衰减低于5%(经LM-80验证),即使在极端热负荷下,色温也能保持稳定。

这种稳定性确保色温比较始终有效——不仅在安装时有效,而且在灯具的整个使用寿命期间也有效。

结论

没有一种通用的“最佳”色温。在办公室里适用的色温,在仓库里可能就不合适;在户外看起来明亮的色温,长时间使用可能会导致眼睛疲劳或眩光。

有效的色温选择取决于应用需求、运行时间、视觉任务和长期稳定性,而不仅仅是初始外观。只有当光源能够常年保持其性能时,比较才具有真正的价值。

通过根据实际使用情况选择色温,并结合稳定的工业级 LED 技术,决策者可以实现更好的舒适性、安全性和投资回报。

如果您需要帮助选择合适的色温或为您的特定应用设计照明解决方案,专业的咨询和光度规划可以决定安装效果的好坏,确保安装的可靠性。

_thumb.jpg)