LED Materials

Fluorescent Transparent Ceramic LED Chip

Excellent LED Chips

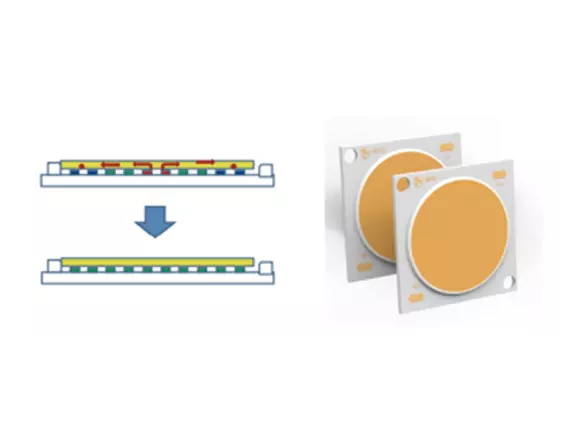

Fluorescent Transparent Ceramic (FTC) LED chips represent the next-generation replacement for traditional phosphor materials that mix phosphor powder with silicone. This innovation enables the development of high-quality, high-power LED light source and laser diode (LD) light sources with exceptional reliability, efficiency, and thermal stability, meeting the demands of industrial, automotive, and outdoor lighting applications.

LED Chip Advantages (1)

LED Chip Performance Highlights:

1). High Internal Quantum Efficiency (IQE): >98%

2). Superior Luminescence Thermal Stability: Maintains brightness under extreme temperatures

3). High Transmittance: Ensures minimal optical loss

4). Excellent Physical and Chemical Stability: Outstanding resistance to corrosion and aging

5). High Thermal Conductivity: Up to 10 W/m·K, enabling efficient heat dissipation for long-term reliability

.webp)

LED Chip Advantages (2)

LED/LD Light Source Performance:

1). Power Range: 150 W – 2000 W

2). High Power Density: Up to 60 W/mm²

3). Reliability: Luminous attenuation <5% over 100,000 hours (LM-80 verified)

4). Long Lifetime: More than 10 years with minimal depreciation

FTC LED enables consistent performance under high power and high thermal load, making it ideal for industrial-grade LED and LD systems.

.webp)

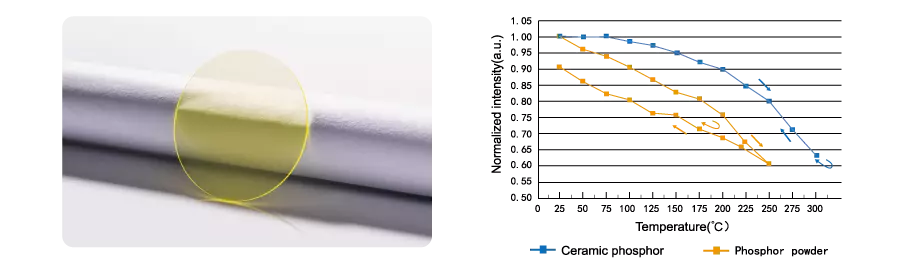

Excellent Luminescence Thermal Stability

The internal quantum efficiency (IQE) of the fluorescent transparent ceramic LED chip at 150℃, 200°C and 250℃ is 1%, 7% and 15% of that at room temperature respectively. While the lQE for the phosphor powder is 22%, 35% and 45% in sequence.

According to LM-80 testing, luminous attenuation of the FTC-based LED chip and LED light source within 100,000 hours of operation is below 5%.

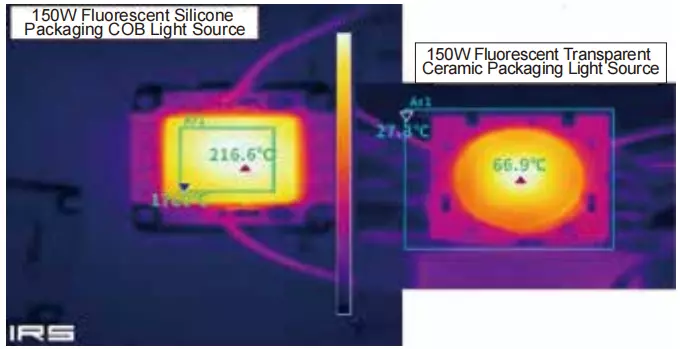

High Thermal Conductivity & Heat Resistance

Engineered with advanced fluorescent transparent ceramic materials, the LED light maintains lower surface temperatures even under continuous operation. Exceptional thermal conductivity ensures efficient heat dissipation, while superior heat resistance protects internal components, extending lifespan and performance stability.

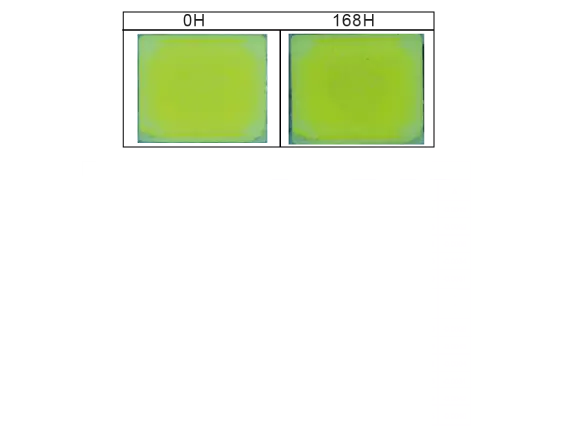

Excellent Sulfur Resistance

The Ceramiclite LED chip features excellent sulfur resistance.

Test conditions:

1. Temperature 40℃, humidity 90%

2. HS concentration: 15ppm

3. Test cycle: 168h

After testing for 168H, the surface of ceramic LED has no change.

Superb Thermal Resistance

The fluorescent transparent ceramic LED chip is packed with great thermal resistance:

①The thermal resistance is 50 times lower compared to traditional phosphor silica gellight source, the lowest data can reach 0.018K/W, the area of the 1000W-COB-LED light source is only 75mm in diameter, the thermal resistance is 0.0375K/W, and the average surface temperature of the light source is only 89℃ when reaching the stable thermal state;

②The service life of high power density and high power LED light source is as high as 10 years, and the depreciation is below 5%;

③The light source has no color temperature difference;

④Strong corrosion resistance against acid and alkali, excellent anti-vulcanization.

Applications

Designed for high-temperature and high-humidity disinfection areas, Ceramiclite’s fluorescent transparent ceramic LED chip delivers reliable performance where durability truly matters.

Roof Lighting for Livestock Farms

(1).webp)

Stadium Lighting for Sports Field

.webp)

Driving Lighting for Cars

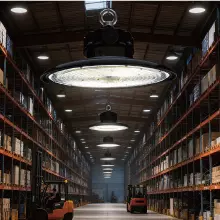

Warehouse Lighting

_thumb.jpg)