Key Material Applications

Replacements of traditional phosphor materials mixing phosphor powder with silicone for high-quality high-power LED and high-power-density LD light sources with high reliability.

Advantages:

FTC: High internal quantum efficiency >98%, excellent luminescence thermal stability,high transmittance, high physical and chemical stability, high thermal conductivity (10 W/m/K).

LED/LD lighting Sources: highpower (150-2000 w), high power density(up to 60W/mm²), high reliability, low luminous attenuation(<5% in 100000 hours).

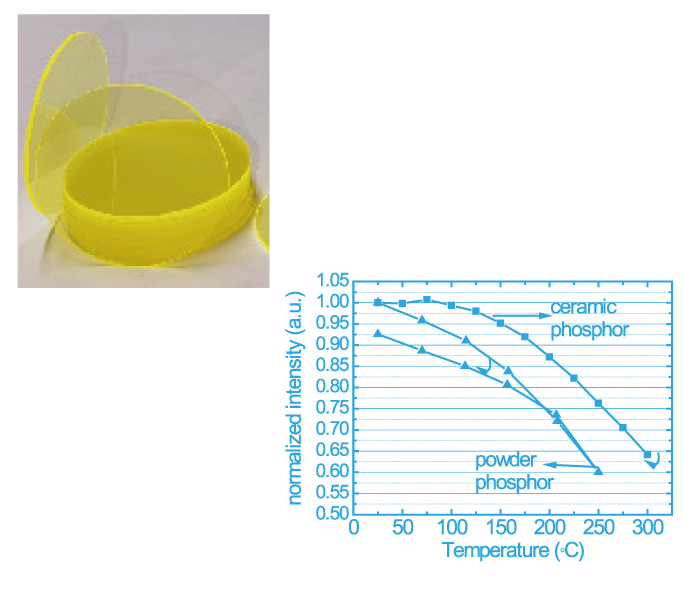

Excellent luminescence thermal stability

The internal quantum efficiency (IQE) of fluorescent transparent ceramic at 150℃, 200°C and 250℃ is 1%, 7% and 15% of that at room temperature respectively. While the lQE for the phosphor powder is 22%, 35% and 45% in sequence.

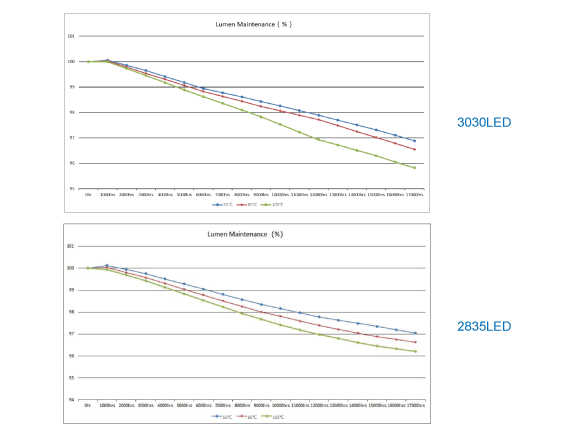

According to LM-80 testing, luminous attenuation of FTC-based LED light source within 100,000 hours operation is below 5%.

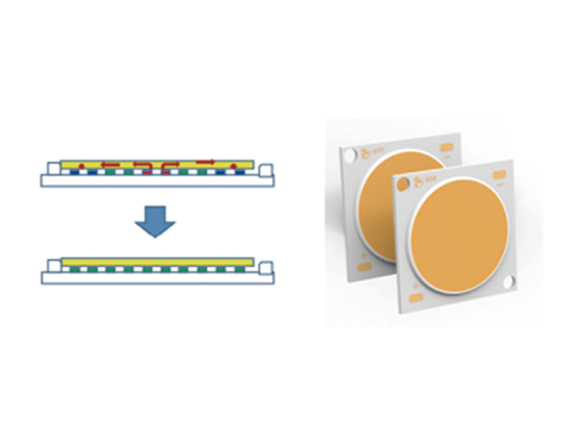

Key technique Ultra-low thermal resistance packaging

Advantages:

①The thermal resistance is 50 times lower compared to traditional phosphor silica gellight source, the lowest data can reach 0.018K/W, the area of the 1000W-COB-LED light source is only 75mm in diameter, the thermal resistance is 0.0375K/W, and the average surface temperature of the light source is only 89℃ when reaching the stable thermal state;

②The service life of high power density and high power LED light source is as high as 10 years, and the depreciation is below 5%;

③The light source has no color temperature difference;

④Strong corrosion resistance against acid and alkali, excellent anti-vulcanization.

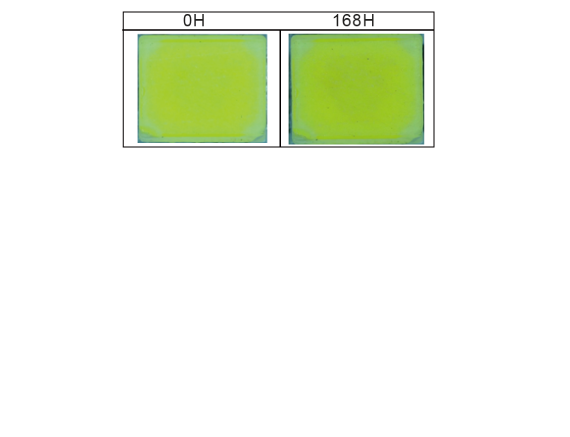

Excellent sulfur resistance

Test conditions:

1. Temperature 40℃, humidity 90%

2. HS concentration: 15ppm

3. Test cycle: 168h

After testing for 168H, the surface of ceramic LED has no change.