仓库照明:4000K 与 5000K 色温对比——生产力与安全性

目录

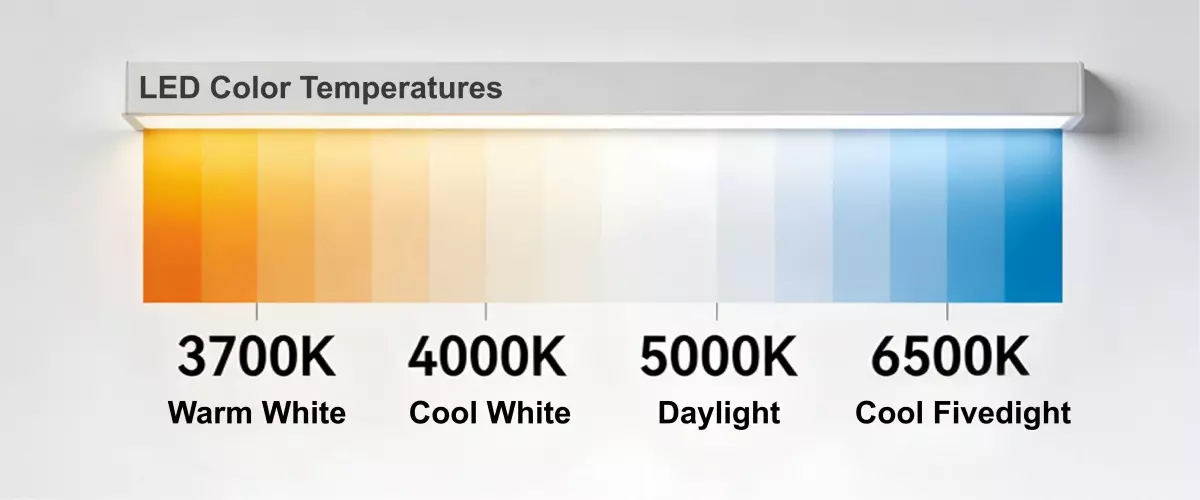

全面对比:3000K vs 4000K vs 5000K vs 6000K

介绍

选择合适的LED色温是设施管理人员最关键的决策之一,但却常常被忽视。在工业环境中,照明不仅仅关乎照明;它直接影响工人安全、拣货/包装错误率以及整体能源水平。通常,争论的焦点集中在两个主要选项上: 4000K 和 5000K。

那么,哪一款更适合您的工厂呢?

直接回答:

对于大多数工业应用而言, 5000K(日光)是高棚灯 的首选标准。 (天花板高度超过 20 英尺)以及精密制造场所, 4000K(冷白光) 更适合天花板较低(低于 15 英尺)、包装站或优先考虑减少眩光和眼睛舒适度而非绝对视觉清晰度的区域。

然而,并非所有情况都适用同一种色温。虽然 4000K 和 5000K 是行业主流色温,但其他色温选择,例如 3000K(用于营造特殊的暖色调氛围)和 6000K(用于临床精准照明),也各有其特定用途。尽管一些制造商提供“可调色温”(CCT 可调)灯具,但大多数企业机构仍然倾向于选择固定色温灯具,以确保工作环境的一致性和可靠性。

在本指南中,我们将详细讲解每种色温的科学原理、对员工的生物影响以及具体应用案例,以帮助您做出正确的投资。

光的科学:什么是色温?

要了解哪种灯最适合您的仓库,我们首先需要解读一些技术术语。

了解开尔文温度标度 (K)

色温以 开尔文 (K)为单位测量。它描述灯泡发出的光的颜色和外观。

较低 的开尔文数(例如 3000K)会产生“温暖的”黄色光,类似于日落或传统的白炽灯泡。

较高 的开尔文数(例如 5000K - 6000K)会产生“冷”的蓝白色光,模拟日光或阴天。

CT 与 CCT:技术上的区别是什么?

你可能会看到CT和CCT这样的术语被交替使用,但它们在科学上是有区别的:

色温 ( CT ):指的是热辐射光源(例如老式白炽灯泡中的灯丝)。受热时,金属会先发出红色光,然后是黄色光,最后是白色光。

相关色温 (CCT ) :由于 LED 发光时不产生热量,因此它们没有“真正”的色温。我们使用 CCT 来描述 LED 的光色与加热金属参考色温之间的相关性。

实用要点:在 LED 行业中,当我们说“色温”时,我们实际上指的是 CCT。

光色与色温

区分规格(色温) 和视觉效果(光色)非常重要 。

l 色温 是一个数字(例如,5000K)。

l 光线颜色 是指人眼感受到的光线颜色(例如,“日光”)。

注意:两盏灯即使色温相同(例如 5000K),如果色调略有不同(偏绿或偏粉),看起来也会略有差异。高品质 LED 灯珠经过严格的等级划分,以确保所有灯具的光色一致。

不要将CCT与CRI混淆

这是买家最常犯的错误。

色温 ( CCT ) 决定了 光的颜色 (黄色、白色或蓝色)。

显色指数 (CRI ) 决定了 该光线下颜色的清晰度和准确性。

例如,色温为 5000K、显色指数 (CRI) 较低的光源可能会使橙色安全背心看起来暗淡无光。对于工业安全应用,我们建议显色指数至少达到 70 或 80, 以确保警示标签和电线颜色清晰可见。

阅读更多:想了解更多?这里有一份关于 LED 色温的全面指南。。

深度解析:明确竞争者

在宣布最终赢家之前,了解每种色温的独特特性至关重要。虽然它们在规格表上看起来可能很相似,但在大型设施中的视觉体验却截然不同。

什么是 4000K?(中性标准)

4000K通常被称为“冷白光”或“中性白光”,是暖光和冷光之间的过渡色温。它发出纯净的白光,略带一丝暖意,消除了较高色温带来的冷冰冰或缺乏生气的感觉。

视觉 体验:想象一下上午十点左右的自然阳光。

主要 特点:它拥有出色的色彩平衡。亮度适中,既能满足工作需求,又足够柔和,即使连续工作8小时也不会感到疲劳。4000K色温常被描述为“护眼”,因此是包装台或装配线等需要长时间保持同一姿势的工作环境的理想选择。

什么是 5000K?(精密标准)

5000K 通常被称为“日光”。顾名思义,它的设计目的是模拟正午时分太阳的光照强度。这种色温的蓝光含量较高,使光线呈现出清爽、冰白的视觉效果。

视觉 体验:想象一下晴朗无云的中午时分,明亮的阳光直射进来。

主要 特点:5000K 色温优先考虑 清晰度。在 5000K 的照明下,细节更加鲜明突出。即使流明输出相同,人眼也会觉得 5000K 的光线比 4000K 的更白更亮。因此,5000K 是需要高度集中注意力和关注细节的场所的首选色温。

4000K 对比 5000K:关键对比

现在来看决策数据。我们从三个直接影响仓库运营的科学维度分析了这些色温。

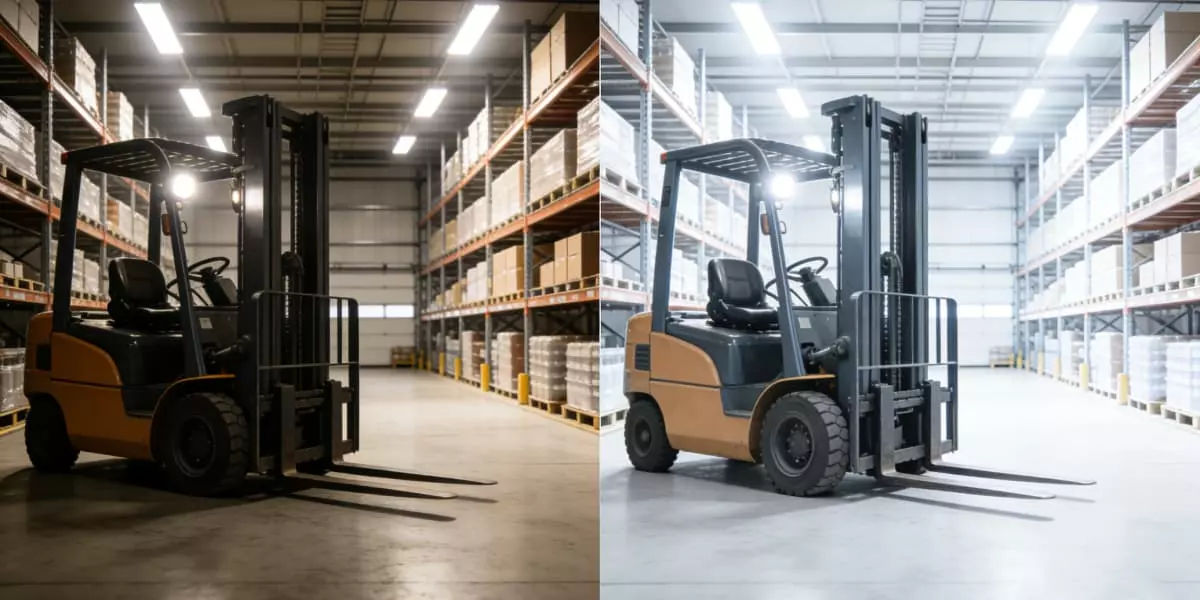

1. 对比度和视觉清晰度

获胜者:5000K

在B2B物流领域,准确性至关重要。5000K色温的照明能够提供卓越的对比度,尤其适用于 白底黑字——这正是货运标签、条形码和库存清单的典型格式。5000K光谱中较高浓度的蓝光能够刺激眼睛的感光细胞,使周围环境看起来更加“清晰”。

根据 照明工程学会 (IES)的指导方针,视觉任务越繁重,所需的对比度就越高。如果您的工厂需要读取细小的零件编号或操作高速叉车,5000K 的色温有助于工人更快地识别物体,从而减少拣货错误。

2. 眩光和眼疲劳

获胜者:4000K

亮度越高并非越好。虽然 5000K 色温能提供清晰度,但如果控制不当,其亮度可能会过于刺眼。在 天花板较低(低于 15-20 英尺)的场所,高强度 5000K LED 芯片会产生明显的眩光,导致“视觉噪声”,长时间工作后眼睛会感到疲劳。

美国职业安全与健康管理局 (OSHA) 标准强调安全工作环境的重要性,确保工作环境免受已知危险因素的影响——而对于抬头看向货架的叉车操作员来说,刺眼的眩光就是一个安全隐患。4000K 色温的灯光自然更柔和,漫射也更均匀,因此是低矮货架或反射表面(例如收缩膜)可能加剧眩光区域的理想选择。

3. 生物学影响(褪黑激素与警觉性)

获胜者:5000K

照明的作用远不止帮助我们看清事物;它还能告诉我们的身体何时应该保持清醒。5000K 的蓝光光谱在这方面 具有优势。科学研究表明,5000K-6500K 范围内的光线会抑制褪黑激素(睡眠激素)的分泌。

对于24小时运营或实行夜班的仓库而言,安装5000K色温的灯具是一项提升生产力的战略举措。它如同“生物咖啡因”,帮助员工在夜班期间保持清醒和专注,从而可能减少疲劳相关的事故。相反,4000K色温的这种抑制作用较弱,能够营造更轻松的氛围。

全面对比:3000K vs 4000K vs 5000K vs 6000K

虽然 4000K 和 5000K 的色温在工业领域占据主导地位,但了解完整的色温范围有助于确保在特定区域不会使用错误的灯光。例如,3000K 的色温对于叉车通道来说可能过于昏暗,而 6000K 的色温对于包装台来说可能过于刺眼。

以下是对各种色温在工业应用中的简要说明:

开尔文 | 外貌 | 最佳工业用途 | 优点和缺点 |

3000K | 暖白 | 休息室、接待处、木材/家具仓库。 | 优点:营造温馨氛围,凸显木纹质感。 缺点:过于放松;降低对比度和警觉性。 |

4000K | 冷白 | 一般仓库、包装站、低矮天花板(<15英尺)。 | 优点:视觉舒适度极佳;眩光低。 缺点:对比度低于 5000K。 |

5000K | 日光 | 高架仓库(>20英尺)、制造、冷藏。 | 优点:高度集中注意力;外观清晰明亮。 缺点:安装过低可能会产生眩光。 |

6000K | 冷日光 | 珠宝检测,精密电子产品组装。 | 优点:精准度极高。 缺点:可能看起来发蓝/无菌。长时间照射可能导致更快出现眼疲劳。 |

应用指南:行业最佳色温

一个设施往往需要多种色温。例如,物流中心可能需要在货架通道使用高对比度照明,而在发货办公室使用柔和的照明。

请使用本指南将您的特定设施类型与行业标准进行匹配:

设施类型 | 推荐 CCT | “为什么” |

普通仓库 | 4000K – 5000K | 高架货架用 5000K;开放式地面堆垛用 4000K。 |

制造/机械加工车间 | 5000K | 对于观察金属零件上的精细细节和读取仪表读数至关重要。 |

冷藏 | 5000K | 明亮的白光使设施看起来更干净、更卫生。 |

包装和质检区域 | 4000K | 减少眩光在这里至关重要,因为工人们需要近距离检查货物。 |

装卸码头 | 4000K – 5000K | 起到连接室外自然光和室内照明的过渡区域作用。 |

如何选择合适的色温(分步指南)

还在犹豫不决?请按照以下4步清单最终确定您的决定。

第一步:检查天花板高度

这是最实用的过滤器。

20 英尺以上(高棚灯):选择 5000K 色温。光线向下传播时会扩散,因此需要 5000K 的强度和“清晰度”来确保在地面上也能看清。

低于 15 英尺(低矮棚):选择 4000K 色温。在这个高度,5000K 色温可能会感觉过曝,并产生令人不适的热点。

步骤二:分析任务

详细组装/阅读:如果工人要阅读标签上的 8 号字体或组装小型电路,请选择 5000K 对比度。

大宗搬运:如果工作涉及搬运托盘和大箱子,4000K 可提供足够的视野,同时带来更好的舒适度。

步骤三:考虑墙面颜色

深色墙壁/地板:它们会吸收光线。使用 5000K 的色温可以改善昏暗的氛围。

白色/浅色墙面:这类墙面会反射光线。4000K 的色温通常足以达到高亮度,而不会造成反射眩光。

第四步:样品测试

照明设计具有主观性。在订购 500 盏灯具之前,最好先购买每种灯具的样品。在实际项目中,我们经常会遇到不同高度的区域,这些区域需要选择不同的色温。

这就是 Ceramiclite HB01 高棚系列的原因 提供全面的定制选项(色温 3000K–6000K,显色指数 70/80)。如果您的设施有特殊要求,我们可以帮助您为每个区域配置所需的具体规格,而不是强行采用“一刀切”的解决方案。

关于LED色温的常见误区

升级到LED照明时,错误信息可能会导致代价高昂的错误。让我们来澄清业内最常见的四个误解。

误区一:开尔文值越高,光线越亮。

事实:这是错误的。亮度单位是 流明,而不是开尔文。5000K 和 4000K 的灯具,如果流明输出相同,则发出的光量也相同。然而,由于 5000K 的对比度更高,且含有更多蓝光,因此人眼通常会感觉更亮。

误区二:所有LED灯都冷冰冰的,缺乏吸引力。

事实:虽然早期的LED灯光线刺眼,但如今的技术已经非常灵活。无论是用3000K的LED灯营造温暖舒适的氛围,还是用5000K的LED灯营造明亮的日光,都能轻松实现。“冷色调”是一种选择,而非限制。

误区三:色温不能混合。

实际情况:虽然统一的色温通常是好事,但有意地混合使用不同的色温对于区域划分也十分有效。例如,为了安全起见,在繁忙的仓库区域使用 5000K 的色温,而在经理的玻璃办公室则使用 4000K 的色温,这样就能形成必要的视觉边界。

误区四:色温越高,能耗越大。

事实:能耗(瓦数)取决于LED驱动器和芯片的效率,而非颜色。同型号的5000K灯和4000K灯消耗的电量完全相同。

常见问题解答

5000K 比 4000K 更亮吗?

严格来说,并非如此。如果流明输出相同,亮度也相同。然而,5000K 提供更高的对比度(感知亮度),使人眼感觉画面更锐利、更明亮。

4000K 和 5000K:哪个对眼睛更好?

这取决于使用时间和天花板高度。一般来说,4000K 更适合长时间使用,尤其是在天花板较低的情况下,能更好地保护眼睛,减少眼部疲劳。5000K 则更适合需要快速看清细节的短时视觉任务。

5000K色温的灯更耗电吗?

不。色温并不影响功耗。一盏150瓦的高棚灯,无论色温是4000K还是5000K,功耗都是150瓦。

5000K 的色温对于仓库来说太白了吗?

对于高棚灯来说并非如此。对于超过 20 英尺(约 6 米)高的天花板,5000K 的色温非常理想,因为光线在到达地面之前就已经扩散开来。然而,对于较低的天花板(低于 15 英尺,约 4.5 米),5000K 的色温可能会显得刺眼且缺乏生气。

高棚照明的最佳色温是多少?

目前高棚照明的行业标准是 5000K。这种色温能够兼顾大型开放空间的视觉清晰度、警觉性和安全性。

结论

在4000K 与 5000K的争论中 ,没有绝对的赢家——只有适合这项工作的工具。

Ø 选择 5000K 色温,适用于高天花板、精确任务和最大限度保持警觉的情况。

Ø 对于天花板较低的场所、包装站和一般视觉舒适度,请选择 4000K。

不要让您设施的安全性和生产力取决于猜测。无论您需要为特定区域提供 3000K 的温暖色调,还是标准的 4000K/5000K 色温,亦或是 6000K 的精准度,Ceramiclite都能 提供完全定制的解决方案(可选 CRI 70/80),以满足您的具体需求。

还有疑问?请立即 联系我们。 购买前,我们提供详细的咨询服务,帮助您了解不同色温在您的空间中实际呈现的效果。

_thumb.jpg)