4000K vs 5000K para iluminación de almacenes: Productividad y seguridad

Tabla de contenido

La ciencia de la luz: ¿Qué es la temperatura del color?

Análisis en profundidad: Definiendo a los contendientes

4000K vs 5000K: La comparación crítica

El espectro completo: 3000K vs 4000K vs 5000K vs 6000K

Guía de aplicaciones: La mejor temperatura de color según la industria

Cómo elegir la temperatura de color adecuada (paso a paso)

Mitos comunes sobre las temperaturas de color de los LED

Introducción

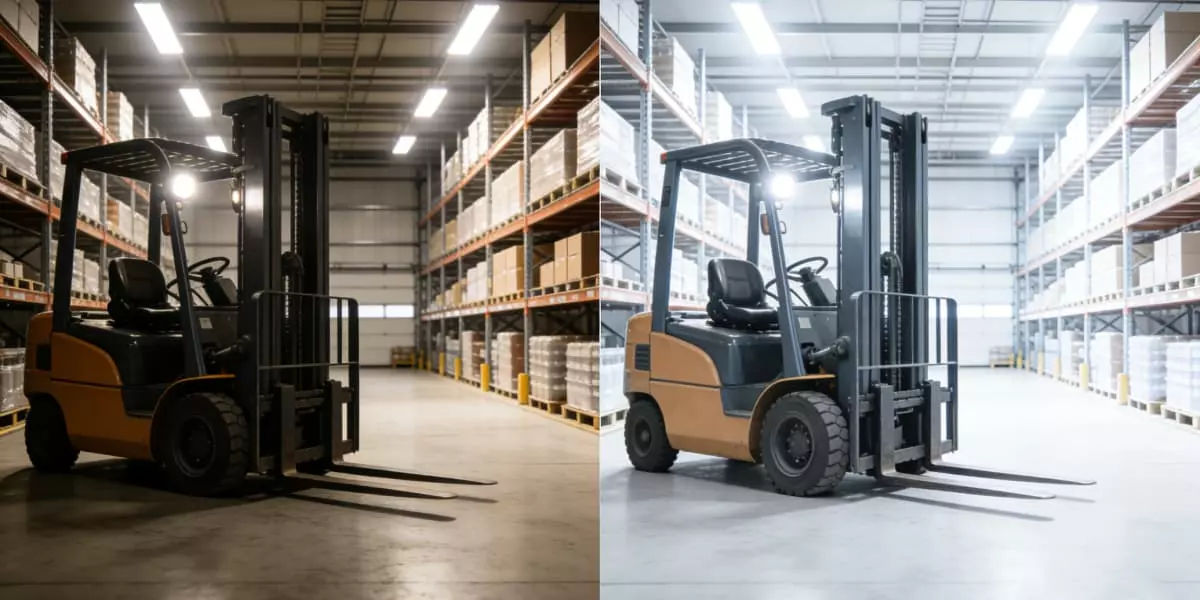

Elegir la temperatura de color LED adecuada es una de las decisiones más importantes que toma un gerente de instalaciones, pero a menudo se pasa por alto. En entornos industriales, la iluminación no se limita solo a la iluminación; también afecta directamente la seguridad de los trabajadores, la tasa de errores en la preparación y el embalaje, y los niveles generales de energía. El debate suele reducirse a dos opciones principales: 4000K vs. 5000K .

Entonces, ¿cuál es el adecuado para sus instalaciones?

La respuesta directa:

Para la mayoría de las aplicaciones industriales, 5000 K (luz diurna) es el estándar preferido para la iluminación de áreas altas. (techos de más de 20 pies) y fabricación de precisión, ya que maximiza el contraste y el estado de alerta. 4000K (blanco frío) es más adecuado para techos más bajos (menos de 15 pies), estaciones de empaque o áreas donde la reducción del deslumbramiento y la comodidad ocular se priorizan sobre la agudeza visual bruta.

Sin embargo, no existe una solución universal. Si bien 4000K y 5000K son las opciones más comunes en la industria, otras como 3000K (para atmósferas cálidas especializadas) y 6000K (para precisión clínica) desempeñan funciones específicas. Si bien algunos fabricantes ofrecen luces "ajustables" (CCT ajustable), la mayoría de las instalaciones empresariales aún prefieren la fiabilidad y la consistencia de las luminarias CCT fijas para garantizar un entorno de trabajo uniforme.

En esta guía, desglosaremos la ciencia, el impacto biológico en sus trabajadores y los casos de uso específicos de cada temperatura de color para ayudarlo a realizar la inversión correcta.

La ciencia de la luz: ¿Qué es la temperatura del color?

Para entender qué iluminación es mejor para su almacén, primero debemos descifrar la jerga técnica.

Entendiendo la escala Kelvin (K)

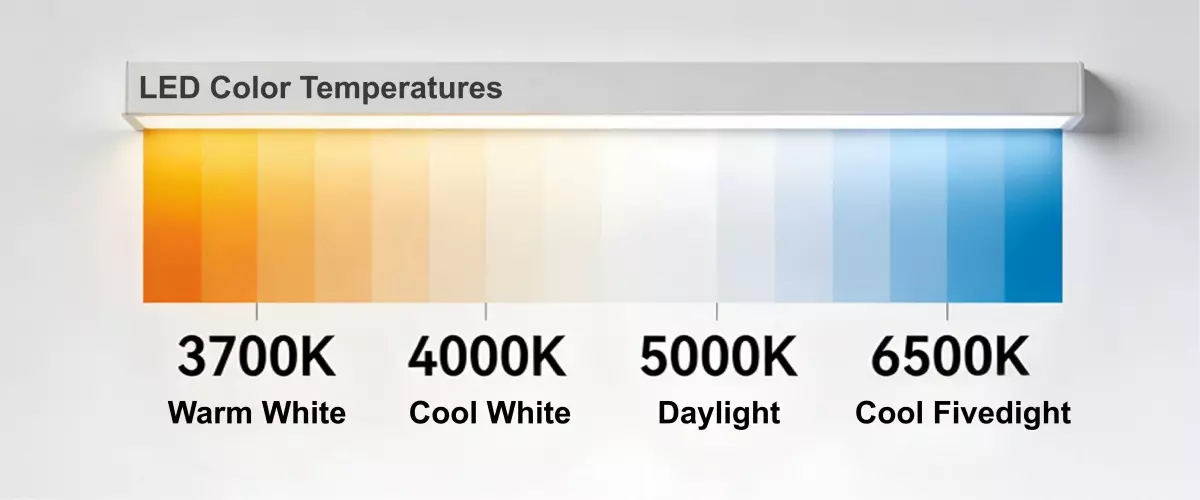

La temperatura de color se mide en grados Kelvin (K) . Describe la apariencia de la luz emitida por una bombilla.

Los números Kelvin más bajos (por ejemplo, 3000 K) producen una luz "cálida" y amarillenta, similar a la del atardecer o a las bombillas incandescentes tradicionales.

Los números Kelvin más altos (por ejemplo, 5000 K - 6000 K) producen una luz "fría", de color blanco azulado, que simula la luz del día o un cielo nublado.

CT vs. CCT: ¿Cuál es la diferencia técnica?

Es posible que vea términos como CT y CCT utilizados indistintamente, pero existe una distinción científica:

l CT (Temperatura de Color): Se refiere a las fuentes de luz que irradian calor (como el filamento de una bombilla incandescente antigua). Al calentarse, el metal brilla en rojo, luego en amarillo y finalmente en blanco.

CCT (temperatura de color correlacionada): Dado que los LED no utilizan calor para producir luz, no tienen una temperatura de color "real". En su lugar, utilizamos la CCT para describir cómo se correlaciona el color de la luz del LED con el metal calentado de referencia .

Conclusión práctica: en la industria del LED, cuando decimos "temperatura de color", técnicamente nos referimos a CCT.

Color de la luz vs. Temperatura del color

Es importante distinguir entre la especificación (temperatura de color) y el resultado visual (color de la luz) .

l La temperatura de color es el número (por ejemplo, 5000 K).

El color de la luz es cómo ese número se percibe al ojo humano (por ejemplo, "Luz del día").

Nota: Dos luces pueden tener la misma temperatura de color (p. ej., 5000 K), pero su color puede variar ligeramente si su tono varía (verdoso o rosado). Los LED de alta calidad se clasifican estrictamente para garantizar la uniformidad del color de la luz en todas las luminarias.

No confundas CCT con CRI

Este es el error más común que cometen los compradores.

l CCT (temperatura de color) determina el color de la luz (amarillo vs. blanco vs. azul).

El CRI (índice de reproducción cromática) determina la claridad y precisión de los colores bajo esa luz.

Por ejemplo, una luz de 5000 K con un IRC bajo podría hacer que los chalecos de seguridad naranjas se vean opacos o apagados. Para la seguridad industrial, recomendamos un IRC de al menos 70 u 80 para garantizar que las etiquetas de advertencia y los colores del cableado sean distintivos.

Leer más : Si desea obtener más información, aquí encontrará una guía completa sobre la temperatura de color del LED..

Análisis en profundidad: Definiendo a los contendientes

Antes de declarar un ganador, es fundamental comprender la personalidad distintiva de cada temperatura de color. Si bien pueden parecer similares en una hoja de especificaciones, la experiencia visual en una instalación a gran escala es muy diferente.

¿Qué es 4000K? (El estándar neutro)

A menudo denominada " blanco frío " o " blanco neutro ", la temperatura de 4000 K es el punto de transición entre la iluminación cálida y la fría. Emite una luz blanca y limpia que conserva un toque de calidez, eliminando la sensación clínica o estéril asociada a las temperaturas de color más altas.

Ø Experiencia visual : Piense en la luz solar natural a media mañana (alrededor de las 10:00 AM).

Característica clave : Ofrece un excelente equilibrio de color. Es lo suficientemente brillante como para ser funcional, pero lo suficientemente suave como para ser cómodo durante turnos de 8 horas. La resolución de 4000 K se describe a menudo como "agradable a la vista", lo que la convierte en la mejor opción para entornos donde los trabajadores permanecen en un mismo lugar durante largos periodos, como en bancos de empaque o líneas de montaje.

¿Qué es 5000K? (El estándar de precisión)

La temperatura de 5000 K se conoce comúnmente como " luz diurna ". Como su nombre indica, está diseñada para imitar la intensidad del sol (mediodía). Tiene un mayor contenido de luz azul, lo que le da una apariencia nítida y blanca como el hielo.

Ø Experiencia visual : piense en la luz solar directa y brillante en un día sin nubes al mediodía.

Característica clave : Prioriza la agudeza visual . Con una iluminación de 5000 K, los detalles resaltan con mayor intensidad. La luz se percibe más blanca y ligeramente más brillante que con 4000 K, incluso con la misma salida de lúmenes. Esto la convierte en la especificación ideal para áreas que requieren alta concentración y un nivel de detalle meticuloso.

4000K vs 5000K: La comparación crítica

Ahora, en cuanto a los datos para la toma de decisiones, hemos analizado estas temperaturas de color en tres dimensiones científicas que impactan directamente en las operaciones del almacén.

1. Contraste y claridad visual

Ganador: 5000K

En la logística B2B, la precisión es fundamental. La iluminación de 5000 K proporciona un contraste superior, especialmente para texto negro sobre fondo blanco : el formato exacto de etiquetas de envío, códigos de barras y listas de verificación de inventario. La mayor concentración de luz azul en el espectro de 5000 K estimula los fotorreceptores del ojo para que perciban el entorno con mayor nitidez.

Según las directrices de la IES (Sociedad de Ingeniería de Iluminación) , las tareas visuales más exigentes requieren niveles de contraste más altos. Si sus instalaciones implican la lectura de números de piezas pequeños o la operación de carretillas elevadoras de alta velocidad, 5000K ayuda a los trabajadores a distinguir los objetos con mayor rapidez, lo que reduce los errores de selección.

2. Deslumbramiento y fatiga ocular

Ganador: 4000K

Más brillante no siempre es mejor. Si bien 5000K ofrece claridad, su intensidad puede ser intensa si no se gestiona correctamente. En instalaciones con techos bajos (menos de 4,5-6 metros) , los chips LED de 5000K de alta intensidad pueden causar un deslumbramiento considerable, lo que genera ruido visual y fatiga visual durante un turno largo.

Las normas de OSHA enfatizan la importancia de un entorno de trabajo seguro libre de peligros reconocidos, y el resplandor cegador es un riesgo de seguridad para los operadores de montacargas que miran hacia los estantes. 4000K es naturalmente más suave y se difunde con más suavidad, lo que lo convierte en la mejor opción para aplicaciones de bahías bajas o áreas donde las superficies reflectantes (como el envoltorio retráctil) pueden exacerbar el resplandor.

3. Impacto biológico (melatonina y estado de alerta)

Ganador: 5000K

La iluminación no solo nos ayuda a ver; también le indica a nuestro cuerpo cuándo debe estar despierto. Es aquí donde el espectro de luz azul de 5000 K ofrece una ventaja funcional. Estudios científicos demuestran que la luz en el rango de 5000 K a 6500 K suprime la producción de melatonina (la hormona del sueño).

Para almacenes que operan 24/7 o que emplean turnos nocturnos, instalar luminarias de 5000K es una medida estratégica para mejorar la productividad. Actúa como una "cafeína biológica", ayudando a los trabajadores a mantenerse alerta y concentrados durante el turno de noche, lo que podría reducir los accidentes relacionados con la fatiga. Por el contrario, las luminarias de 4000K tienen menos efecto supresor, creando un ambiente más relajado.

El espectro completo: 3000K vs 4000K vs 5000K vs 6000K

Si bien 4000K y 5000K dominan el panorama industrial, comprender el espectro Kelvin completo ayuda a garantizar que no use la luz incorrecta en una zona especializada. 3000K puede ser demasiado somnoliento para un carril de montacargas, mientras que 6000K puede ser demasiado duro para un escritorio de embalaje.

A continuación se muestra un resumen rápido de dónde encaja cada temperatura de color en un contexto industrial:

Kelvin | Apariencia | Mejor uso industrial | Pros y contras |

3000K | Blanco cálido | Salas de descanso, Recepción, Almacenes de madera/muebles. | Ventajas: Ambiente acogedor. Realza la veta de la madera. Contras: Demasiado relajante; reduce el contraste y el estado de alerta. |

4000K | Blanco frío | Almacenamiento general, estaciones de embalaje, techos bajos (<15 pies). | Ventajas: Excelente confort visual; bajo deslumbramiento. Contras: Menos contraste que 5000K. |

5000K | Luz | Almacenamiento en gran altura (>20 pies), fabricación, almacenamiento en frío. | Ventajas: Máxima alerta; aspecto "blanco" nítido. Contras: Puede causar deslumbramiento si se instala demasiado bajo. |

6000K | Luz diurna fresca | Inspección de joyas, ensamblaje de dispositivos electrónicos de precisión. | Ventajas: Precisión "clínica". Desventajas: Puede presentar un aspecto azulado o estéril. La exposición prolongada puede acelerar la fatiga ocular. |

Guía de aplicaciones: La mejor temperatura de color según la industria

Una instalación suele requerir varias temperaturas de color. Por ejemplo, un centro logístico podría necesitar una iluminación de alto contraste en los pasillos de estanterías, pero una iluminación más suave en la oficina de envíos.

Utilice esta guía para adaptar su tipo de instalación específica al estándar de la industria:

Tipo de instalación | CCT recomendado | El "por qué" |

Almacén general | 4000K – 5000K | 5000K para racks altos; 4000K para apilamiento en piso abierto. |

Fabricación / Talleres de maquinaria | 5000K | Fundamental para ver detalles finos en piezas metálicas y leer medidores. |

Almacenamiento en frío | 5000K | La luz blanca nítida hace que las instalaciones parezcan más limpias e higiénicas. |

Áreas de embalaje y control de calidad | 4000K | En este caso, la reducción del deslumbramiento es fundamental, ya que los trabajadores inspeccionan las mercancías a corta distancia. |

Muelles de carga | 4000K – 5000K | Actúa como zona de transición entre la luz natural exterior y la iluminación interior. |

Cómo elegir la temperatura de color adecuada (paso a paso)

¿Aún no estás seguro? Sigue esta lista de 4 pasos para tomar tu decisión.

Paso 1: Verifique la altura del techo

Este es el filtro más práctico.

Más de 6 metros (High Bay): Elija 5000 K. La luz se dispersa al descender, por lo que necesita la intensidad y la nitidez de 5000 K para garantizar la visibilidad a nivel del suelo.

Por debajo de 4,5 metros (zona baja): Elija 4000 K. A esta altura, 5000 K pueden resultar abrumadores y crear zonas de alta intensidad incómodas.

Paso 2: Analizar la tarea

Montaje/lectura detallada: si los trabajadores están leyendo fuentes de 8 puntos en etiquetas o ensamblando circuitos pequeños, elija 5000 K para el contraste.

Movimiento de grandes volúmenes: Si el trabajo implica mover pallets y cajas de gran tamaño, 4000K proporciona suficiente visibilidad con mayor comodidad.

Paso 3: Considere los colores de las paredes

Paredes/suelos oscuros: Absorben la luz. Use 5000 K para contrarrestar la penumbra.

Paredes blancas/claras: reflejan la luz. 4000 K suelen ser suficientes para lograr un alto brillo sin causar ceguera por reflexión.

Paso 4: Prueba de muestra

La iluminación es subjetiva. Antes de pedir 500 luminarias, compre una muestra de cada una. En proyectos reales, a menudo vemos zonas de alturas mixtas que requieren diferentes niveles de Kelvin.

Por eso la serie Ceramiclite HB01 High Bay Ofrecemos opciones de personalización completas (3000K–6000K e IRC 70/80). Si sus instalaciones tienen requisitos específicos, podemos ayudarle a configurar la especificación exacta necesaria para cada zona, en lugar de imponer una solución universal.

Mitos comunes sobre las temperaturas de color de los LED

Al actualizar a iluminación LED, la desinformación puede llevar a errores costosos. Aclaremos los cuatro conceptos erróneos más comunes que encontramos en la industria.

Mito 1: Un Kelvin más alto significa una luz más brillante.

Realidad : Esto es falso. El brillo se mide en lúmenes , no en Kelvin. Una luminaria de 5000 K y una de 4000 K con la misma salida de lúmenes emiten la misma cantidad de luz. Sin embargo, la luz de 5000 K suele parecer más brillante al ojo humano debido a su mayor contraste y contenido de luz azul.

Mito 2: Todas las luces LED son frías y poco acogedoras.

Realidad : Si bien los primeros LED eran agresivos, la tecnología actual es versátil. Se pueden lograr ambientes cálidos y acogedores con LED de 3000 K con la misma facilidad que una luz natural nítida con 5000 K. La "frialdad" es una elección, no una limitación.

Mito 3: No se pueden mezclar temperaturas de color.

Realidad : Si bien la uniformidad suele ser buena, la mezcla intencionada resulta eficaz para la zonificación. Por ejemplo, usar 5000 K en la planta activa del almacén por seguridad, mientras que cambiar a 4000 K en la oficina acristalada del gerente crea un límite visual necesario.

Mito 4: Las temperaturas de color más altas consumen más energía.

Realidad : El consumo de energía (potencia) se determina por el controlador LED y la eficiencia del chip, no por el color. Una luz de 5000 K consume exactamente la misma electricidad que una luz de 4000 K del mismo modelo.

Preguntas frecuentes

¿Es 5000K más brillante que 4000K?

Técnicamente, no. Si la salida de lúmenes es la misma, el brillo es el mismo. Sin embargo, 5000K proporciona un mayor contraste (brillo percibido), lo que hace que la imagen se vea más nítida e intensa al ojo humano.

4000K vs. 5000K: ¿Cuál es mejor para la vista?

Depende de la duración y la altura. 4000K suele ser mejor para la comodidad visual a largo plazo y en techos bajos, lo que reduce la fatiga visual. 5000K es mejor para tareas de agudeza visual a corto plazo donde la visión de detalles finos es crucial.

¿Consume más electricidad una temperatura de 5000 K?

No. La temperatura de color no afecta el consumo de energía. Una luminaria de gran altura de 150 W consume 150 vatios, independientemente de si la temperatura es de 4000 K o 5000 K.

¿5000K es demasiado blanco para un almacén?

No para aplicaciones en altura. Para techos de más de 6 metros, 5000K es excelente, ya que la luz se dispersa antes de llegar al suelo. Sin embargo, para techos bajos (menos de 4,5 metros), 5000K puede resultar áspero y clínico.

¿Cuál es la temperatura Kelvin ideal para la iluminación de grandes alturas?

El estándar industrial actual para iluminación de grandes alturas es de 5000 K. Esta temperatura equilibra la claridad visual, la atención y la seguridad en espacios amplios y abiertos.

Conclusión

En el debate de 4000K vs 5000K , no hay un único ganador : solo la herramienta adecuada para el trabajo.

Ø Elija 5000K para techos altos, tareas de precisión y máximo estado de alerta.

Ø Elija 4000K para techos bajos, estaciones de embalaje y comodidad visual general.

No deje la seguridad y productividad de sus instalaciones a la incertidumbre. Ya sea que necesite la calidez de 3000 K para zonas específicas, los estándares de 4000 K/5000 K o la precisión clínica de 6000 K, Ceramiclit e ofrece una solución totalmente personalizada (con opciones de IRC 70/80) para satisfacer sus necesidades específicas.

¿Aún tienes dudas? Contáctanos hoy mismo. para obtener servicios de consultoría detallados para saber exactamente cómo se verán las diferentes temperaturas de color en su espacio antes de comprar.

_thumb.jpg)