Как выбрать цветовую температуру светодиодов: руководство для профессионалов

Оглавление

Введение: Цена неправильного освещения

Основные понятия: CCT, CRI и TLCI

Наука о восприятии: кто видит свет?

Профессиональная шкала Кельвина (визуальная система отсчета)

В центре внимания промышленности: дискуссия о соотношении 4000K и 5000K.

Профессиональный спорт: последовательность — залог успеха.

Специализированное применение: животноводство и сельское хозяйство

Часто задаваемые вопросы по инженерным темам: Развенчание заблуждений

Заключение: Структура принятия решений

Введение: Цена неправильного освещения

В жилых помещениях выбор лампочки часто сводится к эстетическим предпочтениям («Создаёт ли она ощущение уюта?»). Однако в промышленных и профессиональных условиях коррелированная цветовая температура (КЦТ) является критически важным функциональным параметром, напрямую влияющим на безопасность, производительность и эксплуатационные расходы.

Для руководителя объекта или инженера проекта неправильный выбор цветовой температуры в Кельвинах — это не просто досадная мелочь, а потенциальная проблема. Отраслевые исследования и отчеты таких организаций, как IES (Общество светотехников), неизменно показывают измеримую корреляцию между плохими условиями освещения — в частности, несоответствием цветовой температуры — и повышенной утомляемостью работников, более высоким уровнем ошибок в контроле качества и потенциальными инцидентами, связанными с безопасностью труда.

Освещение не бывает "универсальным". Свет с цветовой температурой 3000K, создающий уютную атмосферу в холле отеля, может оказаться катастрофическим в высокоскоростном логистическом центре, где бдительность имеет первостепенное значение. Аналогично, свет с температурой 5000K, идеально подходящий для заводского цеха, может испортить качество трансляции спортивного события из-за несоответствия характеристик сенсора.

В этом руководстве мы выйдем за рамки базового спора о «теплом и холодном» цвете. Мы рассмотрим физику и фотобиологию, лежащие в основе цветовой температуры светодиодов , и поможем вам точно определить, какой показатель Кельвина необходим для остроты зрения человека, датчиков камер или биологических систем.

Независимо от того, модернизируете ли вы склад или проектируете новый стадион, цель одна и та же: световое решение, которое работает точно так, как прогнозируется в симуляциях освещения (DIALux), и обеспечивает стабильные результаты в реальных условиях.

Основные понятия: CCT, CRI и TLCI

Прежде чем переходить к конкретным областям применения, необходимо определить технические параметры, определяющие качество света. В профессиональных спецификациях эти аббревиатуры часто встречаются вместе, но они измеряют совершенно разные свойства.

Понимание шкалы Кельвина (К)

Цветовая температура измеряется в градусах Кельвина (К). Она описывает внешний вид света, излучаемого «излучателем черного тела» (теоретическим объектом) при его нагревании.

Низкая цветовая температура (2700–3000 К): объект светится красно-оранжевым цветом. Это «теплый белый свет».

Средняя цветовая температура (3500–4500 К): свечение переходит в желто-белый оттенок. Это «естественный» или «холодный белый».

Высокая цветовая температура (5000–6500 К): объект светится сине-белым свечением. Это «дневной свет».

Критическая триада: почему CCT недостаточно

Распространенная ошибка в сфере закупок B2B — это выбор светильника, основываясь только на цветовой температуре (например, «Нам нужно 5000K»). Однако два светильника с цветовой температурой 5000K могут выглядеть и работать совершенно по-разному, если игнорировать другие параметры.

1. Цветовая температура ( ЦТ ): определяет цветовое восприятие самого источника света. Желтый он или синий?

2. Индекс цветопередачи ( CRI ): определяет, насколько точно свет отображает истинные цвета объекта по сравнению с естественным солнечным светом. В камере контроля качества (QC) у вас может быть правильная цветовая температура 5000K, но если CRI низкий (<70), ваши инспекторы могут пропустить незначительные цветовые вариации или дефекты. Критические значения всегда измеряются на плоскости задачи , а не только в источнике света.

3. TLCI (Индекс согласованности телевизионного освещения): В то время как CRI предназначен для человеческого глаза, TLCI — для датчиков камеры. В спортивных сооружениях или студиях высокая цветовая температура при низком показателе TLCI приведет к искажению цвета на экране, которое будет сложно исправить при постобработке.

Примечание эксперта : В компании Ceramiclite мы гарантируем, что наши промышленные светильники сочетают высокую эффективность с необходимым спектральным качеством, что подтверждается тщательными испытаниями перед началом любых работ по вводу в эксплуатацию на объекте .

Читайте далее: Хотите узнать больше о том, как выбрать индекс цветопередачи (CRI)? Вот полное руководство по индексу цветопередачи (CRI) .

Наука о восприятии: кто видит свет?

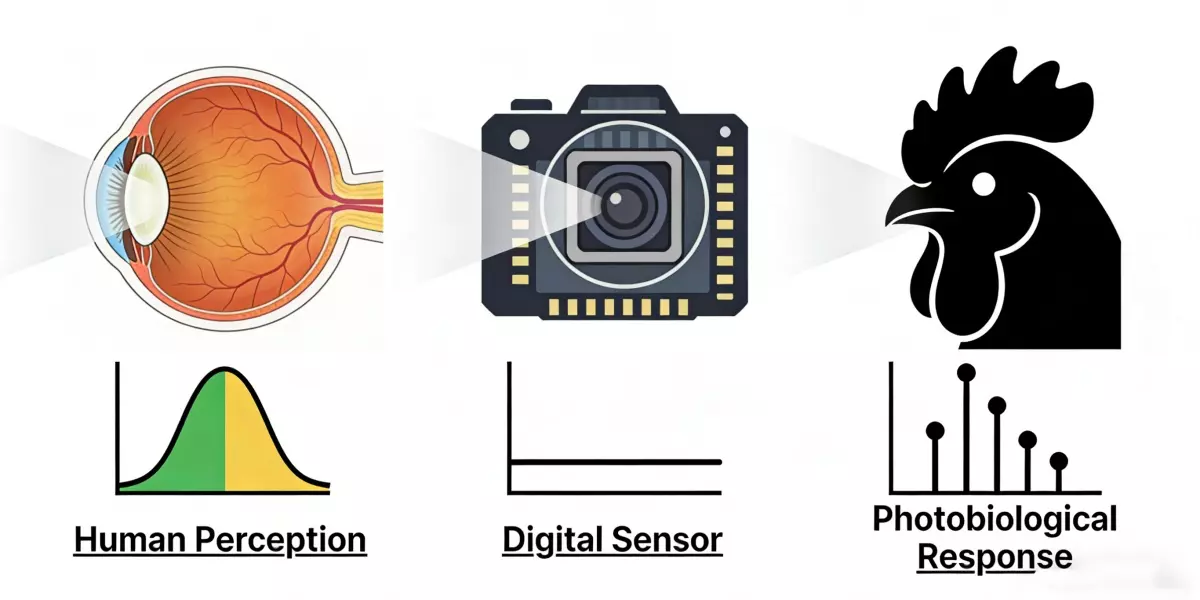

Чтобы выбрать правильную цветовую температуру, необходимо сначала задать себе вопрос: кто — или что — является основным получателем этого света? «Идеальный» свет различается в зависимости от того, обрабатывается ли он человеческим мозгом, кремниевым чипом или биологической системой.

Человеческий глаз: безопасность и циркадные ритмы

Человеческое зрение не статично; оно имеет биологическую природу. Наша сетчатка содержит специализированные клетки, называемые ipRGC (внутриклеточные фоточувствительные ганглиозные клетки сетчатки), которые не являются зрительными, но обладают высокой чувствительностью к синему свету (приблизительно 460–480 нм), который в изобилии присутствует в светодиодных источниках с цветовой температурой 4000–5000K .

Для промышленности: воздействие этого спектра подавляет выработку мелатонина (гормона сна) и стимулирует выработку кортизола. Именно поэтому 5000K является золотым стандартом для сменной работы и производства — он химически сигнализирует мозгу о необходимости оставаться бодрым, снижая количество несчастных случаев, связанных с усталостью.

Острота зрения: Более высокая цветовая температура, как правило, обеспечивает более высокий «скотопический» световой поток, улучшая способность глаза воспринимать глубину и движение в периферийном зрении, что крайне важно для операторов вилочных погрузчиков.

Датчик камеры: баланс белого и его стабильность.

В отличие от человеческого глаза, который мгновенно адаптируется к изменениям цвета (хроматическая адаптация), датчики камер (CMOS/CCD) этого не делают. Им необходима стабильная, конкретная точка отсчета для баланса белого.

Для спортивных трансляций: Профессиональное вещание обычно требует цветовой температуры 5700–6500K, чтобы соответствовать характеристикам дневного света на открытом воздухе. Если цветовая температура светодиодов изменяется из-за проблем с перегревом (распространенная неисправность в более дешевых светильниках), изображение с камеры ухудшится, что приведет к «мутным» цветам в трансляции.

Биологические системы: Фотобиология животноводства

Животные воспринимают свет иначе, чем люди. Например, домашняя птица обладает более широким диапазоном спектральной чувствительности.

В сельском хозяйстве: если человек воспринимает свет как «белый», то курица может считать его чрезмерно интенсивным в красном или ультрафиолетовом спектре. Определенные цветовые температуры можно использовать для регулирования темпов роста, яйценоскости или успокоения птицы. Это требует специализированного подхода, выходящего за рамки стандартных промышленных значений Кельвина.

Профессиональная шкала Кельвина (визуальная система отсчета)

В то время как освещение жилых помещений ориентировано на «атмосферу», профессиональное освещение ориентировано на «функциональность». Для упрощения выбора мы разделили шкалу Кельвина на категории в зависимости от конкретных промышленных и коммерческих применений.

Это ваше краткое справочное руководство:

Ø 3000K (теплый белый) : Не рекомендуется для промышленных рабочих зон. Лучше всего подходит для зон отдыха, архитектурных акцентов или специальных комнат отдыха, где целью является расслабление.

Ø 4000K (нейтральный белый) : базовый уровень для логистики, погрузочных доков и производственных помещений с низкими потолками. Обеспечивает чистый свет без излишней резкости.

Ø 5000K (дневной свет) : промышленный стандарт. Идеально подходит для высотных складов, высокоточного производства и зон контроля качества. Имитирует чистый дневной свет, обеспечивая максимальную контрастность и внимательность.

Ø 5700K+ (холодный дневной свет) : Специализированное применение. Требуется для профессиональных спортивных стадионов (для соответствия телевизионным стандартам) и для выполнения определенных задач по контролю качества в медицине или текстильной промышленности.

![]()

В центре внимания промышленности: дискуссия о соотношении 4000K и 5000K.

Это самый распространенный вопрос, который нам задают менеджеры по эксплуатации зданий: «Какой светильник лучше выбрать для склада — 4000K или 5000K?»

Если раньше стандартом для люминесцентных светильников была цветовая температура 4000K, то для современных промышленных светодиодных светильников для высоких потолков предпочтительным выбором стала 5000K . Вот инженерная логика, лежащая в основе этого изменения.

Почему 5000K — новый стандарт для высоких потолков

Преимущество 5000K заключается в соотношении скотопического и фотопического сигналов (S/P Ratio) .

Научное объяснение : Наши глаза воспринимают яркость по-разному в зависимости от спектра света. Свет с цветовой температурой 5000K содержит больше энергии синего спектра, что вызывает более сильную реакцию зрачка.

Световой поток через зрачок : При освещенности светом с цветовой температурой 5000K зрачок сужается немного сильнее, чем при 4000K. Это создает эффект «камеры-обскуры», увеличивая глубину резкости. Результат? Работники воспринимают пространство как более яркое, а изображения (например, текст на коробке) кажутся более четкими, даже если измеренная мощность одинакова.

Для больших открытых пространств рекомендуется перейти на светодиодные светильники для высоких потолков. Светильник с цветовой температурой 5000K часто создает ощущение большей энергии и улучшает визуальное восприятие помещения.

Влияние на контроль качества и безопасность (на основе данных)

Хорошая видимость напрямую связана с безопасностью. В условиях работы с движущимися погрузчиками и тяжелой техникой скорость реакции имеет решающее значение.

Контрастность : Свет с цветовой температурой 5000K обеспечивает превосходную контрастность по сравнению с более теплыми тонами. Это облегчает человеческому глазу различение отдельных объектов, таких как серый инструмент на сером полу или предупреждающая этикетка на поддоне.

Контроль качества : Для контрольно-измерительных станций точность цветопередачи не подлежит обсуждению. Мы рекомендуем светильники с цветовой температурой 5000K и высоким индексом цветопередачи (CRI). Однако крайне важно измерять эти значения непосредственно на рабочей поверхности , а не только на потолочном источнике света, чтобы убедиться, что света, достигающего рабочего стола, достаточно для обнаружения царапин, вмятин или несоответствий цвета.

Фактор высоты потолка

Все еще не определились? Используйте «Правило высоты потолка» в качестве определяющей основы на этапе планирования:

На высоте более 6 метров (20 футов) используйте цветовую температуру 5000K . На этой высоте свету приходится преодолевать большее расстояние. Четкий, белый свет, достигающий пола, сохраняет свою яркость, не создавая ощущения «мутности».

На высоте менее 4,5 метров (15 футов) допустима цветовая температура 4000K . В помещениях с низкими потолками или небольших цехах, где рабочие физически находятся ближе к светильникам, температура 5000K иногда может казаться слишком интенсивной или стерильной. 4000K обеспечивает несколько более мягкую рабочую среду.

Полезный совет : Прежде чем покупать светильники на тысячи долларов, всегда запрашивайте моделирование освещения (DIALux) . Моделирование позволит точно увидеть, как 4000K и 5000K будут взаимодействовать с вашей конкретной конфигурацией стеллажей и отражательной способностью пола.

Читайте далее : Все еще не понимаете? Мы подготовили для вас подробное руководство по цветовой температуре 4000K и 5000K в освещении складских помещений..

Профессиональный спорт: последовательность — залог успеха.

При освещении спортивных сооружений приоритеты смещаются от «производительности труда» к «удобству для зрителей» и «требованиям к трансляции».

Стандарт вещания (TLCI и 5700K)

Если на вашей площадке проводятся телевизионные мероприятия или планируется трансляция матчей в высоком разрешении, стандартные промышленные светильники, скорее всего, выйдут из строя.

Стандарт : Основные руководящие принципы телевещания (такие как технические требования ФИФА или УЕФА) обычно устанавливают цветовую температуру в диапазоне от 5000K до 6200K . Этот диапазон необходим для соответствия дневному свету на открытом воздухе, позволяя камерам переходить от естественного освещения к искусственному без резких цветовых переходов.

l TLCI : Помимо Кельвина, показатель TLCI (индекс согласованности телевизионного освещения) должен быть высоким (>85 или >90). Это гарантирует, что цвета команды, видимые по телевизору, соответствуют цветам, видимым на стадионе.

Ознакомьтесь с нашими специализированными решениями по освещению спортивных площадок. разработан специально для соответствия этим строгим стандартам.

Скрытый враг: изменение цвета и терморегулирование.

Распространенная неисправность светодиодного спортивного освещения — это «сдвиг цвета». Вы когда-нибудь видели, чтобы освещение на стадионе выглядело фиолетовым или зеленоватым по сравнению с остальными? Это происходит из-за перегрева.

Причина : Мощные спортивные фары выделяют огромное количество тепла. Если не контролировать этот процесс, тепло разрушает люминофорное покрытие на светодиодном чипе, что со временем приводит к необратимому изменению цветовой температуры .

Преимущества Ceramiclite : Здесь важна инженерная разработка. Ceramiclite использует передовую технологию рассеивания тепла с помощью керамики. Благодаря прямому соединению светодиодного чипа с керамикой (которая является превосходным проводником тепла и изолятором от электрических помех), мы поддерживаем низкую температуру перехода.

Результат : установленная вами сегодня цветовая температура 5700K сохранится и через пять лет. Эта стабильность обычно проверяется на месте при вводе в эксплуатацию , что гарантирует равномерность цветопередачи по всему полю, необходимую для профессиональной игры .

Специализированное применение: животноводство и сельское хозяйство

Когда мы переходим от промышленных площадок и стадионов к сельскохозяйственным угодьям, правила стандартной шкалы Кельвина перестают действовать. Это узкоспециализированная область, где фотобиология имеет приоритет над человеческими зрительными предпочтениями.

За пределами человеческого зрения: спектр в Кельвинах

В то время как люди отдают приоритет цветовой температуре (насколько «теплым» или «холодным» кажется свет), животные реагируют в первую очередь на спектральное распределение мощности (СПМ) . Стандартный светодиод с цветовой температурой 5000K, предназначенный для склада, может казаться человеку «белым», но для курицы или коровы в нем может отсутствовать критически важная длина волн, необходимая для их биологических функций.

Исследование на примере птицеводства : Исследования показывают, что определенные спектры вызывают различные биологические реакции у домашней птицы.

Красный спектр (более длинная волна) : часто используется для стимуляции полового созревания и повышения яйценоскости у кур-несушек.

Ø Сине-зеленый спектр (более короткая длина волны) : используется для стимуляции роста мышц у бройлеров и, что особенно важно, для успокоения птиц и снижения агрессии или каннибализма.

Поэтому вопрос «Какой диапазон цветов Кельвина лучше всего подходит для кур?» часто бывает неправильным. Правильный вопрос звучит так: «Какой спектр соответствует моим производственным целям?»

Возможность индивидуальной настройки

Стандартные светодиодные светильники, продающиеся в магазинах, редко оптимизированы для удовлетворения этих биологических потребностей. В Ceramiclite мы выходим за рамки стандартных каталогов. Мы предлагаем индивидуальную настройку , корректируя состав люминофора и выбор чипов для создания специальных «световых рецептов» для молочного животноводства, птицеводства или садоводства.

Для получения более подробной информации о стратегиях освещения, специфичных для каждого вида птицы, посетите наш раздел, посвященный решениям по освещению птицеводческих хозяйств.и решения для освещения животноводческих хозяйств страницы.

Часто задаваемые вопросы по инженерным темам: Развенчание заблуждений

В интернете можно найти множество противоречивых советов. В этой статье наша команда инженеров разъясняет два наиболее распространенных технических вопроса, которые мы получаем на этапе разработки спецификации.

В: Можно ли смешивать цветовые температуры на одном объекте? О: Не в пределах одного поля зрения. Установка светильников с цветовой температурой 3000K и 5000K рядом в одном открытом пространстве — серьезная инженерная ошибка. Это создает эффект «зебровых полос», заставляя человеческий глаз/мозг постоянно корректировать баланс белого. Это приводит к быстрой зрительной усталости, головным болям и потенциальным ошибкам в оценке безопасности.

Однако смешивание температур путем зонирования допустимо и рекомендуется. Например, использование 5000K в зоне высоких потолков склада для повышения бдительности, а использование 3000K в физически отделенной комнате отдыха для сотрудников — для расслабления, — это прекрасное применение психологии освещения.

В: Означает ли более высокая температура в Кельвинах более высокую энергоэффективность? О: Теоретически да, но на практике разница незначительна. Физика диктует, что для создания «теплого» света требуется более плотное люминофорное покрытие, чтобы сместить синий светодиодный луч в сторону красного/желтого. Этот процесс преобразования (сдвиг Стокса) вызывает небольшую потерю энергии. Поэтому чип с температурой 5000K, естественно, немного эффективнее чипа с температурой 3000K.

Однако благодаря современным высокотехнологичным светодиодным технологиям этот разрыв значительно сократился. Разница в эффективности часто составляет менее 5%. Мы настоятельно рекомендуем клиентам отдавать приоритет визуальной пригодности (например, «Могут ли мои работники видеть?»), а не незначительному увеличению экономии энергии на 2%.

Заключение: Структура принятия решений

Выбор правильной цветовой температуры — это не игра в угадайку; это взвешенное решение, основанное на выполняемых задачах и биологических особенностях находящихся в помещении людей.

Используйте этот заключительный контрольный список для разработки стратегии закупок:

Точность и детализация задачи?

n Высокая точность (сборка/контроль качества) →→ 5000K (высокий индекс цветопередачи)

Высота потолка?

n Высокая (>20 футов / 6 м) →→ 5000K

Низкая температура (<15 футов / 4,5 м) → 4000K

Телевизионная трансляция?

Да (ТВ/Стриминг) →→ 5700K (высокий TLCI)

Биологический объект исследования?

n Животноводство/Сельское хозяйство →→ Проконсультируйтесь со специалистом (Индивидуальный спектр)

Не гадайте. Моделируйте.

Прочитать о цветовой температуре — это одно, а увидеть её в собственном помещении — совсем другое. Инвестиции в промышленное освещение — это значительные капиталовложения, поэтому не рискуйте ошибиться.

Готовы увидеть разницу?

Свяжитесь с инженерной командой Ceramiclite уже сегодня. Мы бесплатно создадим модель освещения DIALux для вашего проекта, которая позволит вам наглядно представить, как будут выглядеть различные цветовые температуры в вашем помещении, прежде чем вы потратите хоть доллар.

![]()

_thumb.jpg)