What Is Color Rendering Index? A Professional’s Guide to CRI

Imagine a quality control manager at a textile manufacturing plant in Lyon. Under the factory’s old LED lighting, a batch of premium fabric looks like a deep, consistent black. But when that same fabric arrives at the client’s retail store in London, it looks distinctively Navy Blue.

The result? A rejected shipment, financial loss, and a damaged reputation.

This isn't a vision problem; it is a lighting data problem. In the professional world, light isn't just about brightness (Lumens); it is about accuracy. Whether you are managing a precision workshop, a fresh food market, or a sports arena, the ability of your lighting to render colors authentically is non-negotiable.

This brings us to the most critical metric for light quality: what is color rendering index?

Table of Contents

What is Color Rendering Index?

How is CRI Measured? Beyond the Human Eye

Why CRI Calculation Matters in Your Industry?

Color Rendering Index vs. Color Temperature (CCT)

How to Choose the Right CRI for Your Project?

What is Color Rendering Index? (Defining the Concepts)

To understand lighting quality, we must first clarify three commonly confused terms: CRI, Ra, and TCS.

1. CRI (The Concept)

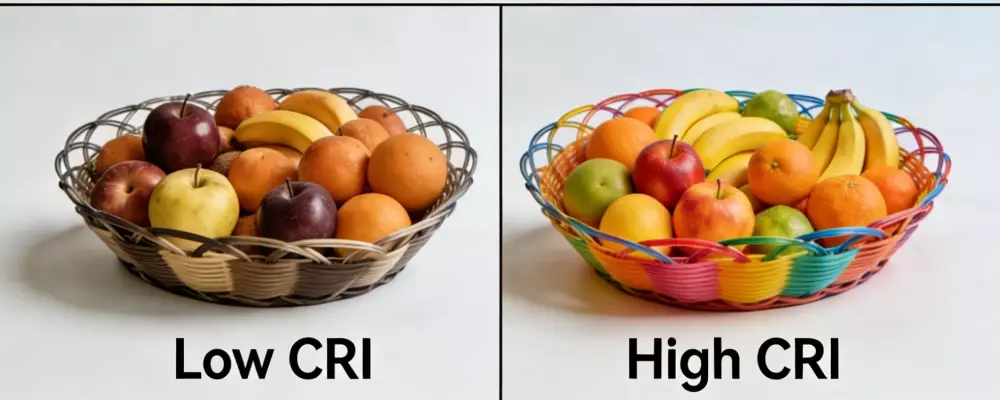

The Color Rendering Index (CRI) is the broad system defined by the CIE to evaluate a light source's ability to reveal the colors of various objects faithfully in comparison with a natural light source (like sunlight). Think of "CRI" as the name of the test.

CRI is a quantitative measure (0-100) of a light source's ability to reveal the colors of various objects faithfully in comparison with a natural or ideal light source (such as sunlight).

u 100: Matches natural daylight perfectly (e.g., the Sun).

u 0: Colors are indistinguishable (e.g., a low-pressure sodium street lamp).

2. Ra (The Metric)

When you see a score like "CRI 80" on a box, it usually refers to Ra (General Color Rendering Index).

Ra is the specific numerical score (0-100) derived from the test.

It is the industry standard "grade" for lighting quality.

3. TCS (The Tool)

Test Color Samples (TCS) are the standardized color palettes used to perform the test. Just as a student is tested on specific subjects, a light source is tested on specific TCS colors to calculate its score.

Why Compliance Matters

For European facility managers, these aren't just definitions; they are rules. The European Standard EN 12464-1 (Light and lighting - Lighting of work places) mandates specific minimum Ra values to ensure visual comfort and safety. Ignoring CRI doesn't just make things look bad—it can make your facility non-compliant.

How is CRI Measured? Beyond the Human Eye

You cannot judge lighting quality just by looking at a bulb. To determine the true Ra score, we use the scientific method established by the CIE (International Commission on Illumination), which relies entirely on the Test Color Samples (TCS).

The Test Color Samples (TCS): The "15 vs. 8" Rule

The CIE standard actually defines 15 specific color samples (TCS01–TCS15) to cover the spectrum of human vision.

Ø TCS01 – TCS08 (R1–R8): These are Pastel Colors (unsaturated shades found in nature).

Ø TCS09 – TCS15 (R9–R15): These are Saturated Colors (deep red, strong blue, vivid green, and skin tones).

Source: ScienceDirect

The Calculation of Ra (General CRI)

Here is the critical detail that separates professional knowledge from basic understanding: Ra only counts the pastels.

The General Color Rendering Index (Ra) is calculated using ONLY the arithmetic mean of the first 8 samples (R1–R8).

Formula for Ra:

Ra = (R1 + R2 + R3 + R4 + R5 + R6 + R7 + R8) / 8

Note: The saturated colors (R9 through R15) are NOT included in this formula.

The "Hidden" Metric: Why R9 Matters

Here is the professional secret that most datasheet summaries hide: The standard Ra calculation ignores Red.

Because Ra only averages the first 8 pastel colors (R1-R8), an LED light can score a respectable CRI 80 while having a terrible ability to render red colors.

l R9 (Saturated Red): This sample measures how well a light renders strong red tones.

l Why it matters: R9 is critical for skin tones (medical), meat freshness (grocery), and timber (furniture).

Many generic industrial LEDs have a negative R9 value, making skin look sickly and wood look green.

At Ceramilcite, we emphasize high R9 values to ensure that what you see is chemically accurate.

Measurement Tools

Do not rely on smartphone apps. Accurate CRI measurement requires a Spectroradiometer or a professional handheld CRI Meter. These devices analyze the full spectral power distribution (SPD) to provide the data required for professional audits.

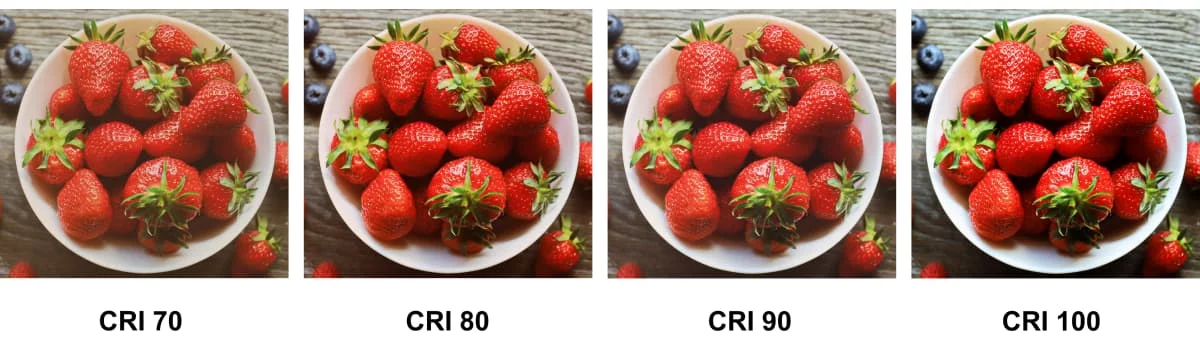

The CRI Spectrum: Standard Hierarchy & Applications

In the European market, there is no "one size fits all." The required Color Rendering Index depends entirely on the visual task at hand.

Below is the hierarchy of CRI standards based on EN 12464-1 requirements and industry best practices. Use this chart to determine the correct specification for your next project.

CRI (Ra) Range | Classification | Typical Applications (European Standards) |

90 - 100 | Excellent / Critical | Clinical Examination (Medical): Essential for diagnosing skin conditions. Color Matching: Textile printing and graphic arts where ISO 3664 applies. Fresh Food Display: Butcher shops and produce (High R9 required). Art Galleries: Preventing color distortion in artwork. |

80 - 89 | Good / Standard | Offices & Classrooms: The minimum standard for occupied areas per EN 12464-1. Precision Assembly: Industrial electronics or detail work. Retail: General clothing and merchandise. |

60 - 79 | Fair / Basic | General Warehousing: Forklift operations where color ID is not critical. Outdoor Areas: Street lighting, parking lots, and loading docks. Heavy Industry: Steelworks or foundries. |

< 60 | Poor | Security Lighting: Purely for visibility, not identification. Construction Sites: Temporary lighting. (Note: Not recommended for permanent indoor workplaces). |

Why CRI Calculation Matters in Your Industry

In professional environments, lighting specifications directly impact operational success. However, the requirement varies drastically between a shipping warehouse and a televised stadium.

For Industrial & Manufacturing (Textile, Food, Logistics)

In industrial settings, the goal is often a balance between Visual Clarity and Energy Efficiency.

The Cost of Error: In manufacturing and logistics, poor color rendering can lead to safety hazards (misreading color-coded labels) or efficiency drops (difficulty distinguishing components). Industry reports indicate that upgrading lighting quality can reduce accident rates by ensuring safety signage and hazardous zones are clearly visible.

The Standard:

l Critical QC Zones: Textile inspection tables typically require specialized CRI 90+ sources (D65).

l General Production & Warehousing: For the vast majority of the floor space—spinning lines, packaging areas, and high-rack storage—CRI 80 is the European industry standard (EN 12464-1). It offers much better visual comfort than the old CRI 70 lamps but maintains higher energy efficiency than studio lights.

The Ceramilcite Solution:

We understand that industrial facilities cannot ignore electricity costs. Ceramilcite’s industrial LED High Bay series focuses on the "Sweet Spot" for manufacturing. We provide robust CRI 70 and CRI 80 options.

This allows facility managers to install efficient, bright lighting that meets safety and identification standards for general industrial tasks, without the unnecessary energy consumption of gallery-grade fixtures.

For Sports Lighting & Broadcasting (Stadiums)

Sports lighting is unique because it must satisfy two different audiences: the players on the field and the cameras broadcasting the game.

The Problem: A light source might look bright enough to a player's eye, but cause "flicker" or color shifts when viewed through high-definition slow-motion cameras.

The Application Hierarchy:

Ø Class III (Training & Recreational): For local clubs and training fields, visibility is priority number one. CRI 70 is the standard accepted level to balance budget and brightness.

Ø Class II (Regional Competition): Requires better color definition for spectators. CRI 80 is typically recommended.

Ø Class I (Televised Events): Professional broadcasting requires CRI 90+ and high TLCI scores to ensure the grass looks green and team kits look accurate on TV.

The Ceramilcite Flexibility:

Ceramilcite offers a tiered approach to match your venue’s specific needs. We do not force a one-size-fits-all solution. Our sports lighting range includes:

l High-Efficiency CRI 70/80 models: Perfect for maximizing lumens on training grounds and municipal fields.

l High-Performance CRI 90 options: Designed for venues with broadcasting requirements, ensuring your facility is future-proof for televised events.

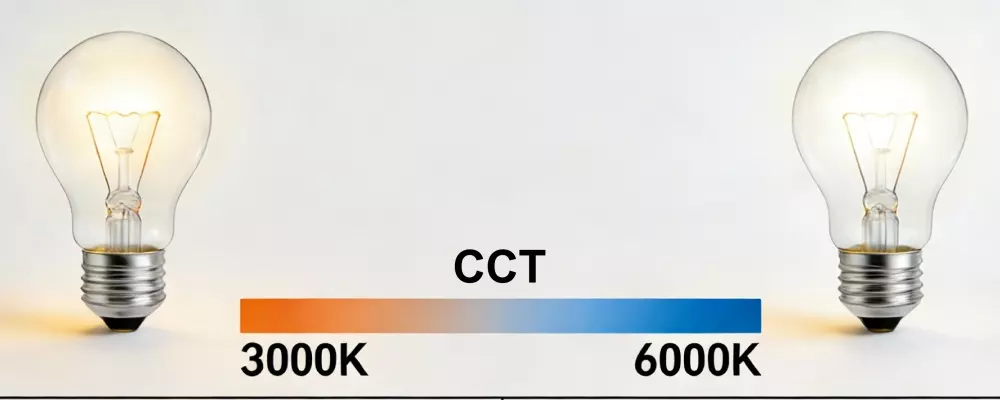

Color Rendering Index vs. Color Temperature (CCT)

When upgrading to LED, buyers often confuse "Color Temperature" (the mood) with "Color Rendering" (the quality). Understanding the difference is key to avoiding disappointment.

Clarification: The Two Pillars of Light

1. CCT (Correlated Color Temperature):

u Question: "What color is the light itself?"

u Scale: Measured in Kelvin (K).

u Range: From Warm (3000K) to Cool (6500K).

u Use: 3000K creates a cozy atmosphere; 5000K promotes alertness.

2. CRI (Color Rendering Index):

u Question: "How true do objects look under this light?"

u Scale: Measured in Ra (0-100).

u Range: From Poor (<70) to Excellent (>90).

u Use: Determines if a red apple looks red or brown.

The Spectrum Connection (Semantics)

Why can two lights have the same CCT (e.g., 4000K) but look completely different? The answer lies in the Spectrum.

Cheap LEDs often achieve white light by mixing a strong blue spike with yellow phosphor, leaving gaps in the red and cyan spectrum. This might create the correct "color temperature," but it results in a hollow light quality where colors feel flat.

Ceramilcite’s Approach:

We utilize advanced LED chip technology to optimize the spectral distribution. Whether you choose our CRI 80 industrial lights or CRI 90 sports lights, our engineering focus is on creating a balanced spectrum. This ensures that for your specific application—whether it's spotting a forklift in a warehouse or tracking a football in a stadium—the visual information is conveyed accurately and comfortably.

Read more: Want to know more about CCT? Here is a complete guide on Color Temperature.

If you'd like to learn more about technical knowledge about lighting, here is a guide on Lighting Glossary for you.

How to Choose the Right CRI for Your Project?

Selecting the correct Color Rendering Index is a balancing act between Visual Quality, Energy Efficiency, and Budget. You don't always need the highest number; you need the right number for your specific application.

Use this checklist to define the exact requirements for your facility:

✅ Check Your Compliance (EN 12464-1)

Are you lighting a permanently occupied workspace like an office or a precision workshop? European standard EN 12464-1 generally mandates a minimum of Ra ≥ 80 to ensure employee well-being and visual comfort.

✅ Check Your Task & Budget (The Ra 70 Option)

Not every area needs gallery-quality light.

u The Cost-Saver: For high-ceiling logistics warehouses, outdoor storage yards, or amateur training fields, color discrimination is often secondary to brightness and cost.

u The Benefit: Choosing CRI 70 fixtures for these zones allows you to maximize lumen output and reduce energy consumption. If your goal is simply "detection" rather than "inspection," Ceramilcite’s CRI 70 Industrial and Sports series offer the most economical solution.

✅ Check Your Precision Needs

Does your task involve judging product quality based on color?

u Industrial: If you are grading meat, mixing paints, or inspecting textiles, you cannot compromise. You need Ra ≥ 90.

u Sports: For top-tier stadiums hosting televised matches, standard lighting isn't enough. You need broadcast-ready specifications to capture the action accurately.

✅ Check the Efficiency Trade-off

There is a rule of physics: typically, as CRI goes up, lumen output goes down.

u The Challenge: A CRI 90 chip usually produces fewer lumens per watt than a CRI 70 chip.

u The Ceramilcite Balance: We engineer our fixtures to minimize this loss. Whether you choose our high-efficiency CRI 70 models or our high-fidelity CRI 90 models, we ensure the thermal management and driver efficiency are optimized to give you the best possible light output for your energy dollar.

Conclusion

For too long, Color Rendering Index has been treated as a footnote in lighting specifications. But as we have seen, whether you are managing a textile plant in Milan or a football stadium in Manchester, CRI is not a vanity metric—it is a productivity tool and a safety baseline.

l Low CRI (70) is your workhorse for efficiency in large, non-critical spaces.

l Standard CRI (80) is your compliance baseline for human-centric workplaces.

l High CRI (90+) is your specialist tool for precision and broadcasting.

Don't leave your facility's visual performance to chance.

Ready to optimize your lighting plan?

Stop guessing with generic specs. Contact a Ceramilcite Specialist to discuss which CRI level offers the best ROI for your specific project.

_thumb.jpg)