工业LED高棚灯:完整指南

大空间需要强大的照明功率——而这正是工业LED高棚灯 发挥作用的地方。

如果您曾经想过如何在不浪费能源或金钱的情况下照亮大型工业空间,本指南将带您了解您需要知道的一切。

目录

什么是工业LED高棚灯?

工业LED高棚灯 听起来很高端,但原理其实很简单——它是专为普通灯具无法满足需求的高层空间而设计的照明设备。例如,工厂、仓库或飞机库等天花板高度超过20英尺(约6米)的场所。

当屋顶离地面很远时,你需要强劲而集中的光线,确保光线能够照射到地面。这正是高棚灯的设计初衷。

过去,金属卤化物灯或荧光灯等传统照明方式 是首选,但说实话——它们发热量大、耗电量高,而且总是在最糟糕的时候烧坏。

工业LED灯反过来想,它们在消耗大约一半能源的情况下,就能提供相同(甚至更高)的亮度,而且在考虑维护之前,可以持续发光 5 万小时甚至更久。

简而言之,它们是更智能、更坚固、更高效的大型工业空间照明方式。合适的高棚灯系统可以将昏暗沉闷的仓库变成明亮、安全、节能的工作空间。

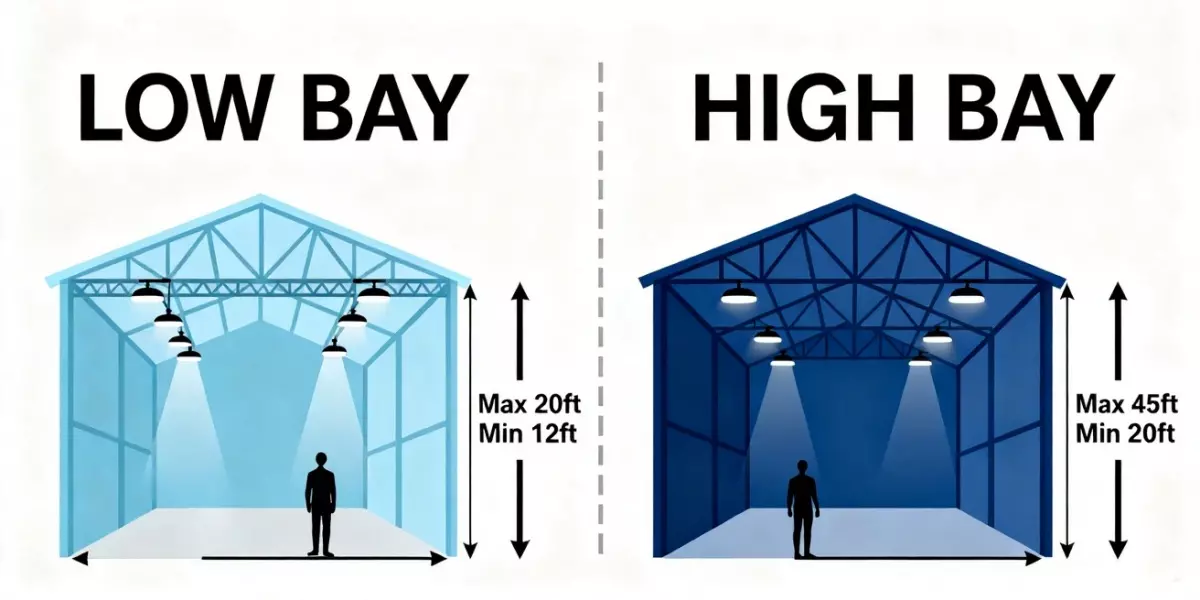

高棚灯与低棚灯——主要区别

你是否曾经走进两家不同的工厂,发现一家光线明亮如阳光,而另一家光线均匀柔和?这种差异通常源于高棚灯和低棚灯——这两种照明系统是为截然不同的天花板高度和照明需求而设计的。

高棚灯专为高处空间(通常为20 英尺或更高) 设计,在这些空间中,光线需要传播更远距离并保持强度。它采用较窄的光束角 ,将光线集中照射到下方的工作区域。

另一方面,低棚灯更适合20英尺以下的房间,它采用更宽的光束角 ,将光线均匀地照射到较短的距离上。它非常适合车间、零售区和车库等不需要远距离“照明”的场所。

以下是一个简单的对比图表,以便更清楚地说明:

特征 | 高棚照明 | 低棚照明 |

安装高度 | 超过 20 英尺(6 米) | 低于 20 英尺(6 米) |

光束角 | 窄(60°–120°) | 宽(120°以上) |

应用程序 | 仓库、工厂、体育馆、机库 | 车间、车库、零售商店、走廊 |

光分布 | 聚焦、明亮、反射较少 | 更柔和、均匀的照明 |

维护 | 难以到达,但寿命长 | 更易于维护,更换频率更高 |

简而言之——选择灯具时应考虑高度,而非形状。如果灯具需要从高高的天花板向下照射,那就选择高棚灯。对于较小的房间或较低的天花板,低棚工业LED照明灯是更明智的选择。

工业LED高棚灯的类型

每个工业空间都有自己的个性——有些狭长如仓库通道,有些宽阔如工厂车间。

因此,LED高棚灯主要 有三种设计:线性高棚灯、UFO型LED高棚灯和模块化高棚灯。每种类型都适用于不同的工作空间和照明目标。

以下是简要概述:

类型 | 非常适合 | 主要特点 | 典型形象 |

线性高棚灯 | 仓库、通道、生产线 | 光线分布均匀,非常适合狭长区域。 | 矩形或条形 |

UFO LED高棚灯 | 开放空间——工厂、体育馆、车间 | 结构紧凑、功能强大、易于安装 | 圆形、碟状设计 |

模块化高棚灯 | 大型工业园区,定制项目 | 可调节模块、可扩展亮度、维护简便 | 板式结构 |

类型 1:线性高棚灯

线性高棚灯是仓库和生产通道 的理想之选。它们细长的矩形灯体能将光线均匀地投射到整个通道上,非常适合需要从一端到另一端亮度一致的场所。它们可以巧妙地安装在货架之间,减少阴影,让您的工作空间安全舒适,呵护您的双眼。

类型 2:UFO LED 高棚灯

UFO LED高棚灯 结构紧凑、圆润坚固,专为对高度和照射范围要求极高的开放式工业区域而设计 。尽管体积小巧,它们却能提供令人印象深刻的亮度和出色的光束控制。其设计也使得安装异常简便——只需悬挂、连接即可。是需要强劲均匀照明的工厂、车间和体育馆的理想之选 。

类型 3:模块化高棚灯

对于需要灵活性的项目,模块化高棚灯 是切实可行的解决方案。其模块化结构意味着您可以组合多个 LED 面板以提高输出功率,或调整光束方向以适应布局。它们广泛应用于大型工业厂房或定制照明系统中 ,在这些应用中,性能和可扩展性缺一不可。

简而言之——线性灯 使过道明亮均匀,UFO 灯 轻松应对开放空间,模块化灯 让您完全掌控。

高棚LED灯用于哪些场所?

高棚LED灯在哪里? 真正闪耀?在天花板很高、工作很严肃的地方,照明就不能马虎。

这些灯具是仓库、工厂、车间、体育馆,甚至是飞机库的首选——基本上,任何需要从上方获得明亮、稳定照明的空间都适用。

在仓库 和配送中心,照明需要深入货架之间,且不能产生阴影。线性高架灯 是理想之选——它们能将均匀的光线投射到长长的通道上,使工作人员能够清晰地看到每一个条形码。

在工厂 和生产车间,亮度和安全性至关重要。机器、工具和人员都在快速移动,因此强劲均匀的照明可以减少事故和眼部疲劳。UFO或模块化高棚灯可以轻松应对这些高强度任务,确保一切清晰可见且高效运行。

车间照明 值得单独关注。无论是金属加工、汽车维修还是精细装配工作,这些空间都需要清晰明亮的光线和聚焦的视野。高棚LED灯能够提供工人所需的清晰无阴影照明,并具有出色的色彩精准度,便于区分不同的材料和表面处理。

在体育馆或运动场馆,舒适度才是关键。你需要充足的光线,但又不能有眩光,确保运动员能看清球,而不是被星星遮挡。高棚LED灯平衡了光照强度和漫射效果,营造出明亮而舒适的环境。

无论空间大小,合适的灯具设计——例如用于过道的线性灯具、用于开放区域的UFO灯具、用于定制的模块化灯具——都能确保你的照明不仅仅是发光;它还能像你一样努力工作。

工业LED高棚灯的三大优势

为什么这么多工厂都在用LED高棚灯替换金卤灯或荧光灯?

这不仅仅是跟上技术潮流的问题——更重要的是以更低的成本获得更好的照明效果。工业LED高棚灯将高效、可靠和高性能完美融合于一体,长期来看,其投资回报显而易见。

优势一: 节能省电

我们先来说说最显而易见的优势——节能。LED高棚灯比金属卤化物灯节能60-70% ,比荧光灯节能约40% 。它们能将更多电能转化为光能而非热能,这意味着您无需将工厂变成烤箱就能获得更明亮的照明。简而言之:更节能、更明亮、更省电。

优势二: 寿命长且易于维护

还在为30英尺高天花板上的灯泡频繁更换而烦恼吗?LED灯可以彻底解决您的问题。LED灯的使用寿命长达5万至10万小时,是金属卤化物灯的五到十倍。这意味着更少的更换次数、更少的停机时间,以及更轻松的维护工作。仓库和工厂等工业场所尤其需要这种稳定性。

优势三: 光线质量与性能

LED高棚灯在光照质量方面也表现出色(名副其实)。它们拥有高达80以上的显色指数(CRI),提供自然、精准的色彩,有效缓解眼部疲劳。无需预热,无闪烁——从打开开关的那一刻起,即可享受纯净稳定的光线。

没有闪烁,没有等待,没有故障——只有干净、稳定的光线。

快速对比:LED照明与传统照明

特征 | LED高棚灯 | 金属卤化物 | 荧光 |

能源效率 | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

寿命 | 50,000–100,000 小时 | 10,000 小时 | 15,000–20,000 小时 |

热身时间 | 立即的 | 5-10分钟 | 立即的 |

中央研究所 | 80岁以上 | 65–70 | 75 |

维护 | 低的 | 高的 | 中等的 |

LED高棚灯不仅仅是替代品,更是升级之选,它重新定义了工业空间的照明方式。

工业LED高棚灯的投资回报率是多少?

改用工业LED高棚灯 不仅仅是照明升级,更是一项明智的商业决策。许多设施管理人员首先会问自己一个简单的问题:“这样做真的划算吗?” 答案是肯定的——而且通常比您预期的更快见效。

快速积累的节能效果

能源成本是照明预算中最大的一笔开支。 与金属卤化物灯具相比, LED高棚灯的耗电量可减少50%至70% ,比荧光灯系统减少约40% 。对于一个仓库来说,如果安装100盏400瓦的LED灯具,每年大约可以节省1万至1.5万美元 (具体金额取决于当地电价和营业时间)。

用电量减少,产生的热量减少——你的照明费(和空调费)都会下降。

提示:查看您所在公用事业公司的补贴计划——许多公司为升级到 LED 照明系统提供现金奖励。

使用寿命更长,维护成本更低

这里还有另一个隐藏的投资回报率因素:维护成本。LED高棚灯的寿命通常为5万至10万小时,这意味着您可以8至10年 才需要更换一次。相比之下,金属卤化物灯每1至2年就需要更换灯泡。

这意味着更少的升降机使用、更少的梯子操作,以及更少的生产中断。在工业环境中,节省的每一小时维护时间,就意味着避免了一小时的工时损失。

实际投资回收期:3-5年

在大多数工业应用中,LED升级可在3到5年内收回投资。之后,节省的能源和维护成本就全部转化为利润。

例如,一家每年照明支出为 2 万美元的工厂,改用 LED 照明后,成本可降至 7000 美元左右,每年节省 1.3 万美元。五年下来,节省的金额显而易见。

电子表格之外的投资回报率

当然,LED灯的经济效益固然显著——但它还能改善照明质量、提升员工安全和舒适度,从而间接提高生产效率。更好的照明意味着更少的错误和更快乐的员工。

简而言之: 工业 LED 高棚照明不是一项支出;而是一项投资,它会逐步收回成本,一次打造一个明亮的工作空间。

如何规划您的高层仓库布局?

工业LED照明的关键不在于选择最佳灯具,而在于如何规划布局。数量和亮度这两个问题才是构建良好照明方案的真正要素。

让我们一起来看看如何在不把工厂车间变成聚光灯舞台或洞穴的情况下,把这两件事都做好。

第一步:测量空间

在进行任何计算之前,先从基础做起:测量你的空间。你需要:

面积: 以平方米或平方英尺为单位

天花板高度: 天花板越高,所需的灯光强度就越大。

表面反射率: 明亮的墙壁比黑暗的墙壁更能反射光线。

用途: 生产线、仓库或检验区需要不同的亮度级别

仓库和健身房的面积可能相同,但它们所需的照明水平绝对不同。

步骤二:估算灯具数量

测量完成后,这里有一个快速估算所需灯具数量的方法。

一般公式如下:

灯具数量 ≈ (目标照度 × 面积) ÷ (每盏灯具流明数 × 利用率)

假设你有一个1000 平方米的仓库,目标照度为300 勒克斯,并且你使用26000 流明的 高棚灯。为了获得均衡的照明覆盖,你大约需要12-14 个灯具 。

当然,像Dialux 或Relux这样的专业照明设计软件 可以提供更精确的结果,但这种简单的计算可以为你制定预算提供一个可靠的起点。

步骤 3:选择合适的亮度(高棚灯流明表)

以下是一个简单的参考图表,可帮助您将天花板高度与理想的照明输出相匹配:

安装高度 | 每盏灯具推荐流明数 | 典型应用 |

20–30 英尺 | 22,000–35,000 流明 | 仓库,车间 |

31–40 英尺 | 35,000–47,000 流明 | 工厂、健身房、机库 |

40英尺以上 | 47,000+流明 | 重工业、飞机停机坪 |

道理很简单:天花板越高,灯具的功率就应该越大。 灯光太暗,会出现昏暗的角落,存在安全隐患;灯光太亮,则会浪费电能和金钱。关键在于找到平衡点。

第四步:微调以提高效率

掌握了基本要领之后,通过调整合适的波束角度 和布局模式进行优化:

宽光束(120°): 更适合低矮天花板和开放空间

窄光束(60°–90°): 非常适合高天花板或需要集中照明的区域

把它想象成灯光编排——合适的灯光布置可以让每个角落都明亮起来,同时又不会增加你的电费。

结论

工业LED高棚照明不仅仅关乎亮度,更关乎效率、安全性和真正的投资回报率。通过改用LED照明,工厂和仓库可以降低能源成本、减少维护,并在未来数年内打造更安全、更明亮的工作环境。

准备好迈出下一步了吗?

探索 Ceramiclite 专 为各种工业环境设计的 HB01 LED 高棚灯,或联系我们的专家进行免费照明审核。 看看你能省多少钱。

常见问题解答

问1:LED高棚灯可以用于户外吗?

答:可以——只要它们的防护等级达到IP65或更高。这个等级意味着它们具有足够的防尘和防水性能,可以用于户外或半户外场所,例如装卸码头或有顶棚的体育场。但千万不要把室内灯具直接放在雨中,否则它们会损坏。

问2:LED高棚灯可以调光以实现灵活的照明控制吗?

当然可以。许多Ceramiclite型号支持0-10V调光 或智能控制,让您可以根据工作需要或日光条件调节亮度。这不仅方便,还能节能并延长灯具寿命。您可以把它想象成为您的工厂打造专属的氛围照明(但是为了提高生产效率,而不是为了营造浪漫氛围)。

问3:Ceramiclite高棚灯提供哪些保修服务?

我们的大多数灯具都提供8年保修,涵盖性能和零部件。因为工业照明并非短期投资——我们对售出的每一流明都负责。

问题四:LED高棚灯的使用寿命有多长?

通常为5万至10万小时,具体取决于使用情况和环境。这相当于大约10年 的可靠照明——远长于金属卤化物灯或荧光灯。简而言之:一次安装,多年无忧。

Q5:LED灯只是昙花一现的潮流吗?

绝无可能。LED灯代表着工业照明的未来——节能高效、智能化、经久耐用。真正会被淘汰的是传统白炽灯泡。

Q6:更换灯具时应该如何处理旧灯泡?

金属卤化物灯泡和荧光灯泡通常含有需要妥善回收或处理的材料。Ceramiclite 的支持团队可以帮助您联系经过认证的回收商,确保您的升级过程清洁、安全且符合相关规定。

_thumb.jpg)