Leitfaden für LED-Hallenleuchten

Inhaltsverzeichnis

LED-Hallenbeleuchtung im Vergleich zu herkömmlichen Metallhalogenlampen/HPS-Lampen

Wichtigste Vorteile der LED-Hallenbeleuchtung

Wie wählt man die besten LED-Hallenstrahler für Geschäfte aus?

Anwendungsbereiche der industriellen LED-Hallenbeleuchtung

Was sind LED-Hallenstrahler?

LED-Hallenstrahler sind für Räume mit Deckenhöhen von typischerweise über 6–12 Metern konzipiert . In dieser Höhe können herkömmliche Leuchten nicht genügend Helligkeit oder gleichmäßige Ausleuchtung gewährleisten. Daher sind Hallenstrahler mit höherer Lichtausbeute, optimierten Abstrahlwinkeln und besserem Wärmemanagement ausgestattet, um eine gleichmäßige Beleuchtung großer Flächen zu gewährleisten.

Sie werden häufig verwendet in:

Lagerhäuser und Logistikzentren

Produktionsanlagen und Werkstätten

Turnhallen, Hangars, Supermärkte, Messehallen

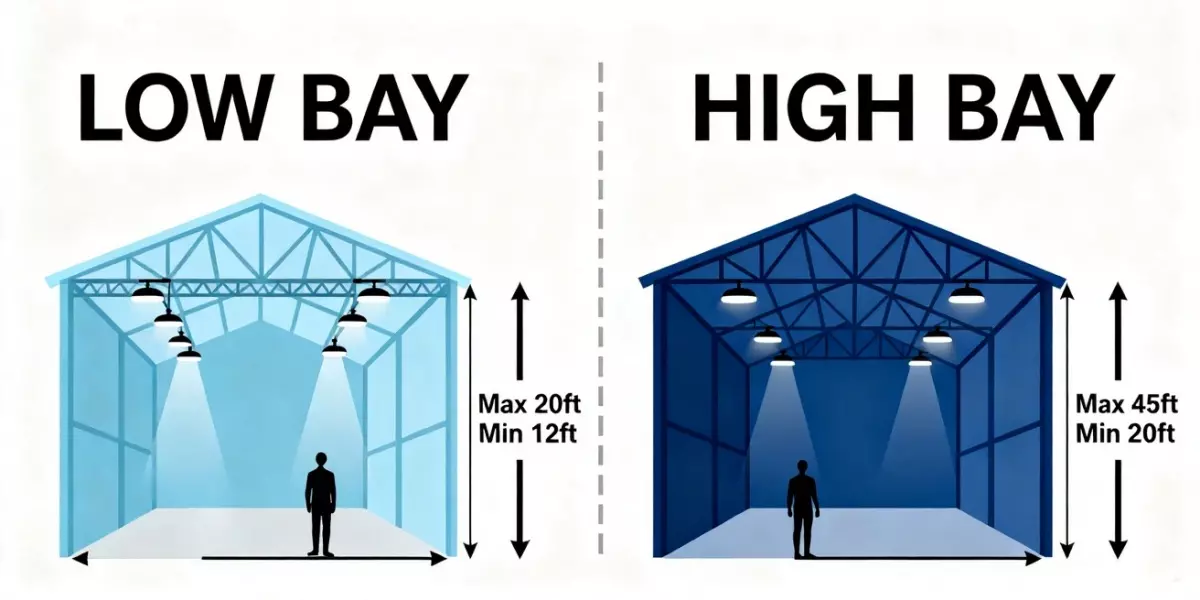

Hochbucht vs. Niedrigbucht – Was ist der Unterschied?

Besonderheit | LED-Hallenleuchten | LED-Hallenleuchten |

Deckenhöhe | Über 6–12 m | 4–6 m |

Strahlwinkel | Schmaler (60°–120°) zur Fokussierung des Lichts nach unten. | Breiter, um kurze Distanzen abzudecken |

Lichtstrom | Höher, üblicherweise 15.000–40.000 lm | Niedriger, geeignet für Einzelhandel oder kleine Werkstätten |

Vereinfacht gesagt: Bei hohen Decken und großen Räumen benötigt man LED-Hallenstrahler, um dunkle Stellen und Schatten zu vermeiden.

Wenn Sie mehr über die Unterschiede zwischen Hallenbeleuchtung und Beleuchtung für niedrige Hallen erfahren möchten, schauen Sie sich diesen Blog an: Hochregal- vs. Niedrigregalbeleuchtung: Was ist der wirkliche Unterschied?

Arten von LED-Hallenstrahlern

In Industriehallen gibt es viele verschiedene Funktionsbereiche. Deshalb sind LED-Hallenstrahler in unterschiedlichen Formen und Montagearten erhältlich. Die Wahl des richtigen Typs trägt dazu bei, die Lichteffizienz zu verbessern, Blendung zu reduzieren und sicherzustellen, dass das Licht genau dort ankommt, wo es am meisten benötigt wird.

1. Runde/UFO-Hallenstrahler

UFO-LED-HallenleuchtenSie sind rund, kompakt und für hohe Decken konzipiert.

Ihre kreisförmige Form erzeugt einen breiten und gleichmäßigen Lichtstrahl und macht sie daher ideal für:

Produktionsanlagen

Turnhallen und Sporthallen

Flughäfen und Hangars

Vorteile

Schlankes Design, einfache Montage mit Haken oder Halterung

Bessere Wärmeableitung dank Aluminiumgehäuse

Hohe Lichtleistung (100–240 W) mit 150–160 lm/W

Nachteile

Weniger geeignet für schmale Gänge oder Regalsysteme

2. Lineare Hallenstrahler

Lineare Hallenstrahler sehen aus wie lange Rechtecke, ähnlich wie herkömmliche Leuchtstoffröhren. Sie verteilen das Licht in einem rechteckigen Muster und eignen sich daher perfekt für strukturierte Räume.

Ideal für:

Lagerhallen im Gangstil mit hohen Regalen

Supermärkte und Einzelhandelsgeschäfte

Produktionslinien

3. Nachrüstsätze für Hallenstrahler und Hallenstrahler für Werkstätten

Diese Leuchten sind so konzipiert, dass sie alte Metallhalogenid- oder Leuchtstofflampen modernisieren können, ohne dass der gesamte Leuchtenkörper ausgetauscht werden muss.

Übliche Anwendungsgebiete:

Kleine Werkstätten und Garagen

Einzelhandelsgeschäfte mit hohen Decken

Anlagenmodernisierungen bei begrenztem Budget und Installationszeit

✅ Vergleichstabelle

Typ | Ideale Anwendungsbereiche | Vorteile | Einschränkungen |

UFO LED-Hallenleuchte | Fabriken, Turnhallen, Hangars | Kompakte Größe, hohe Helligkeit, ausgezeichnete Wärmeableitung | Nicht ideal für Gänge oder lange Regalanordnungen |

Lineare LED-Hallenbeleuchtung | Lagerhallen, Supermärkte, Logistikzentren | Gleichmäßige Ausleuchtung von Gängen und Regalen, einfache Ausrichtung an Regalsystemen | Größer, schwerer zu installieren |

Nachrüstsätze / Hallenstrahler | Garagen, kleine Lagerhallen, Einzelhandelsgeschäfte | Kostengünstige Modernisierung, minimaler Verkabelungsaufwand | Geringere Lichtleistung im Vergleich zu vollwertigen Hallenstrahlern |

LED-Hallenbeleuchtung im Vergleich zu herkömmlichen Metallhalogenlampen/HPS-Lampen

Viele Lagerhallen und Fabriken nutzen noch immer Metallhalogenid- (MH), Natriumdampf-Hochdrucklampen (HPS) oder Leuchtstofflampen für Hallenbeleuchtung. Obwohl diese Technologien einst Industriestandard waren, zeichnen sie sich durch hohen Energieverbrauch, kurze Lebensdauer und häufigen Wartungsaufwand aus. LED-Hallenleuchten lösen die meisten dieser Probleme.

1. Gängige traditionelle Hochregallager-Optionen

Traditioneller Lichttyp | Typische Verwendung |

Metallhalogenid (MH) | Stadien, alte Fabriken, Industriebeleuchtung |

Hochdruck-Natrium (HPS) | Lagerhallen, Parkplätze, Straßenbeleuchtung |

Leuchtstoffröhren-Hallenbeleuchtung (T5/T8) | Einzelhandelsgeschäfte, kleine Werkstätten, Fitnessstudios |

2. Leistungsvergleich: LED-Beleuchtung vs. herkömmliche Beleuchtung

Besonderheit | LED-Hallenbeleuchtung | Metallhalogenid (MH) | Hochdruck-Natrium (HPS) | Fluoreszierend |

Lichtausbeute | 130–160 lm/W | 70–90 lm/W | 80–110 lm/W | 60–90 lm/W |

Startzeit | Sofort (0,5s) | 5–10 Minuten | 2–5 Minuten | Sofort |

Lebensdauer | 50.000–100.000 Stunden | 10.000–15.000 Stunden | 15.000–24.000 Stunden | 20.000–30.000 Stunden |

Wartungskosten | Sehr niedrig | Hoch (Lampen- und Vorschaltgerätwechsel) | Medium | Medium |

Wärmeleistung | Niedrig | Sehr hoch | Hoch | Medium |

Farbwiedergabe (CRI) | ≥80 | 60–70 | 20–30 (gelblich) | 70–80 |

Energieverbrauch | Niedrigster | Hoch | Mittel-hoch | Medium |

3. Warum LED die bessere Wahl ist

✔ Bis zu 70 % Energieeinsparung im Vergleich zu Metallhalogenid- oder Natriumdampflampen

✔ Keine Aufwärmzeit – LEDs schalten sich sofort ein ✔ Längere Lebensdauer = weniger Austausch und geringere Arbeitskosten ✔ Bessere Lichtqualität (Farbwiedergabeindex, Gleichmäßigkeit, flimmerfrei) ✔ Geringere Wärmeentwicklung , wodurch der Bedarf an Klimaanlagen in Fabriken oder Lagerhallen reduziert wird ✔ Optionale Smart-Funktionen : Dimmung, Bewegungssensoren, drahtlose Steuerung

Kurz gesagt, der Wechsel von Metallhalogenid- oder Leuchtstoffröhren-Hallenstrahlern zu LEDs ist nicht nur ein Trend – es ist eine langfristige, kostensparende Entscheidung.

Wichtigste Vorteile der LED-Hallenbeleuchtung

LED-Hallenstrahler sind heutzutage die bevorzugte Wahl für Lagerhallen, Fabriken und andere große Einrichtungen, da sie eine bessere Leistung bei geringeren Betriebskosten bieten. Zu den wichtigsten Vorteilen zählen:

1. Bis zu 70 % Energieeinsparung

Herkömmliche Metallhalogenid- oder Natriumdampf-Hochdrucklampen verbrauchen 250–400 W pro Leuchte. LED-Ersatzleuchten benötigen oft nur 100–150 W und liefern dabei die gleiche oder sogar eine höhere Helligkeit. Das bedeutet:

Geringerer Stromverbrauch

Niedrigere monatliche Stromrechnungen

Schnellerer ROI für Industrieanlagen

2. Längere Lebensdauer, geringerer Wartungsaufwand

LED-Hallenstrahler haben typischerweise eine Lebensdauer von 50.000 bis 100.000 Stunden , während Metallhalogenlampen nur etwa 10.000 Stunden halten.

Dies reduziert:

Häufiger Glühbirnenwechsel bei hohen Decken

Arbeitskosten für Wartungsteams

Produktionsausfallzeiten in Fabriken oder Lagern

3. Helle, gleichmäßige und angenehme Beleuchtung

Hohe Lichtausbeute gewährleistet klare Sicht vom Boden bis zur Decke.

Ein hoher Farbwiedergabeindex (CRI ≥ 80) zeigt die wahren Farben von Produkten, Maschinen und Sicherheitsschildern.

Kein Flimmern oder Summen – verbessert den Sehkomfort und die Produktivität der Mitarbeiter.

Eine gleichmäßige Lichtverteilung reduziert dunkle Flecken und Schatten.

4. Langlebiger und industrietauglicher Schutz

Die meisten LED-Hallenstrahler sind wie folgt konstruiert:

Schutzart IP65 (wasserdicht und staubdicht)

Aluminiumgehäuse für schnelle Wärmeableitung

Stoßfeste Linsen für raue Industrieumgebungen

5. Intelligente Steuerungs- und Dimmoptionen

LED-Hallenstrahler lassen sich integrieren mit:

0–10V-Dimmsysteme

Bewegungssensoren (schalten sich nur ein, wenn sich jemand in der Nähe befindet)

Tageslichtsensoren und drahtlose Steuerungssysteme

Diese Funktionen helfen, zusätzlich Energie zu sparen und die Lichtautomatisierung zu vereinfachen.

Wie wählt man die besten LED- Hallenstrahler für Geschäfte aus ?

Bei der Auswahl der richtigen LED-Hallenleuchte geht es nicht nur um die Wattzahl. Ziel ist es, Helligkeit, Abstrahlwinkel, Installationsmethode und Arbeitsumgebung optimal auf die Bedürfnisse Ihrer Einrichtung abzustimmen. Folgendes sollten Sie beachten:

1. Wattzahl-Ersatz (100 W / 150 W / 200 W)

LED-Lampen benötigen deutlich weniger Energie als Metallhalogenidlampen (MH), um die gleiche Helligkeit zu erzeugen.

Metallhalogenid (MH) | LED-Ersatz | Typische Verwendung |

250 W | 100-W-LED | Kleine Werkstätten, Garagen |

400 W | 150-W-LED | Standardlager, Fabriken |

600 W | 200-W-LED | Turnhallen, Logistikzentren |

Die Auswahl erfolgt anhand der Deckenhöhe, des erforderlichen Beleuchtungsstärkepegels und der Größe des Arbeitsbereichs.

2. Lumen & Lichtausbeute

Achten Sie auf Lampen mit ≥150 lm/W .

Höhere Lumen pro Watt = mehr Licht bei geringerem Energieverbrauch.

Beispiel: Eine 150-W-LED mit 150 lm/W = 22.500 Lumen.

3. Farbtemperatur (CCT)

CCT-Bereich | Helle Farbe | Geeignet für |

4000K | Neutralweiß | Lagerhallen, Montagelinien |

5000K | Kühles Tageslicht | Fertigungs- und Inspektionsbereiche |

5700K+ | Sehr kühles Weiß | Aufgaben im Freien oder mit hohem Kontrast |

Für industrielle Beleuchtung ist ein Farbtemperaturbereich von 4000–5000 K am angenehmsten – hell, aber nicht zu kalt.

4. CRI (Farbwiedergabeindex)

Für Bereiche, in denen es auf Farbgenauigkeit ankommt (Inspektion, Verpackung, Qualitätskontrolle), wird ein CRI ≥ 80 empfohlen.

Lampen mit niedrigem Farbwiedergabeindex (CRI) können Farben verfälschen und die visuelle Ermüdung verstärken.

5. IP-Schutzart, Blendung und Abstrahlwinkel

Besonderheit | Was zu beachten ist |

IP-Schutzart | Schutzart IP65 oder höher für staub-, feuchtigkeits- und ölbeständige Umgebungen |

UGR (Blendungskontrolle) | Linsen oder Diffusoren mit niedrigem UGR-Wert helfen, Blendung am Arbeitsplatz zu vermeiden. |

Strahlwinkel | 60° für hohe Decken, 90° für Allgemeinbeleuchtung, 120° für offene Bereiche |

6. Montageoptionen

Montageart | Beschreibung | Am besten geeignet für |

Hakenhalterung | Schnelle Installation, am häufigsten | Lagerhallen, Werkstätten |

Kettenbefestigung | Höhenverstellbar | Einzelhandel, Supermarktregale |

Halterung / Oberflächenmontage | Fest und stabil | Niedrige Decken, schräge Dächer, Tunnel |

✅ Kurze Checkliste vor dem Kauf

✔ Ersetzt es Ihre aktuelle MH- oder HPS-Lampe?

✔ Liefert es mindestens 150 lm/W?

✔ Ist die Farbtemperatur für die Arbeitsumgebung geeignet?

✔ Farbwiedergabeindex (CRI) höher als 80?

✔ Schutzart IP65 oder höher für raue Umgebungsbedingungen?

✔ Passender Abstrahlwinkel und Montageart für Ihre Decke?

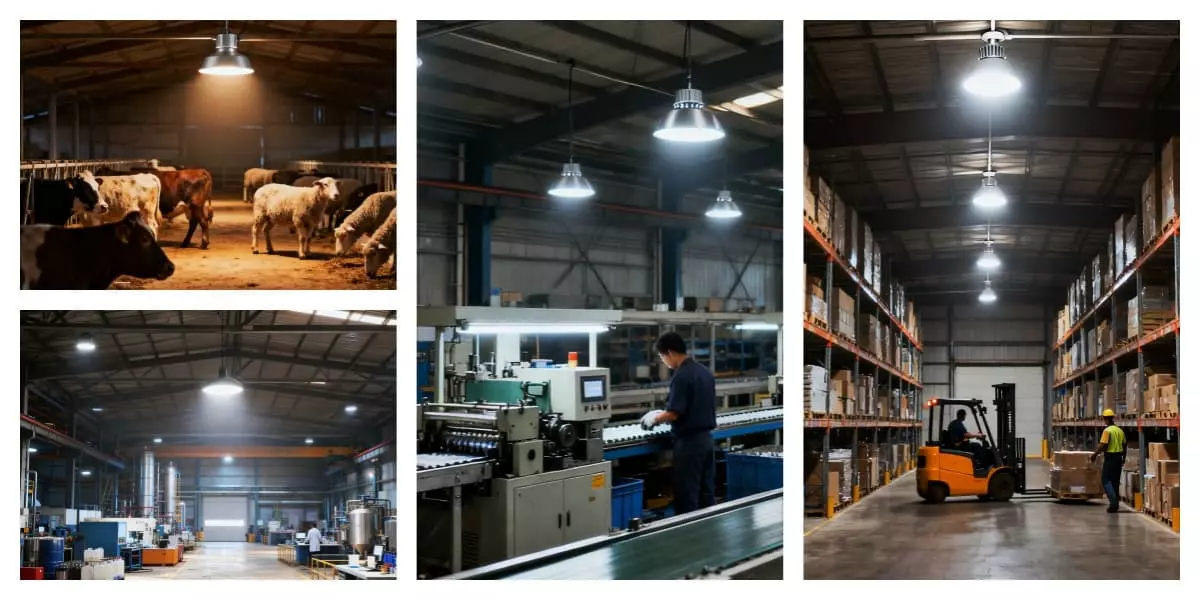

Anwendungsbereiche der industriellen LED-Hallenbeleuchtung

LED-Hallenstrahler sind für große Räume mit hohen Decken konzipiert, in denen helle, gleichmäßige und energieeffiziente Beleuchtung für Sicherheit und Produktivität unerlässlich ist. Im Folgenden werden die gängigsten Anwendungsbereiche und die Vorteile von LED-Hallenstrahlern für die jeweilige Umgebung erläutert.

1. Lagerhäuser und Logistikzentren

Sorgen Sie für eine gleichmäßige Ausleuchtung zwischen hohen Regalen und Lagergängen.

Um die Sicherheit von Gabelstaplern zu verbessern, sollten Schatten und dunkle Ecken reduziert werden.

Optionale Bewegungssensoren helfen, in Bereichen mit geringem Verkehrsaufkommen Energie zu sparen.

2. Produktionsanlagen und Werkstätten

Hoher Farbwiedergabeindex (CRI) und flimmerfreie BeleuchtungGenauigkeit bei Montage- und Prüfaufgaben verbessern

Dank ihrer geringen Wärmeabgabe schaffen LEDs einen komfortableren Arbeitsplatz.

Das robuste Aluminiumgehäuse ist im Werkszustand staub-, öl- und vibrationsbeständig.

3. Viehställe

Die einstellbare Farbtemperatur simuliert natürliches Licht und fördert so das Wachstum der Nutztiere und die Futterverwertung.

Das abgedichtete, korrosionsbeständige Gehäuse widersteht Feuchtigkeit und Abfall und gewährleistet so eine langfristige Nutzung.

Energieeffizientes Design senkt die Kosten für die 24-Stunden-Beleuchtung in Scheunen.

4. Chemische Umgebung

Die explosionsgeschützte Konstruktion erfüllt die Sicherheitsstandards für Bereiche mit brennbaren Chemikalien.

Die korrosionsbeständige Beschichtung widersteht sauren/alkalischen Dämpfen und verhindert so Schäden.

Eine stabile Lichtleistung ohne Flimmern gewährleistet klare Sicht bei chemischen Prozessen.

5. Kühlhäuser und Lebensmittelverarbeitungsanlagen

LEDs funktionieren auch bei niedrigen Temperaturen (–30°C und darunter) gut.

Keine Glasröhren oder giftigen Materialien, sicherer für lebensmittelverarbeitende Umgebungen

Eine geringere Wärmeabgabe trägt zur Aufrechterhaltung stabiler Kühlbedingungen bei.

Kurz gesagt: Überall dort, wo hohe Decken und Sicherheit, Energieeffizienz und Sichtbarkeit wichtig sind, sind LED-Hallenstrahler die zuverlässigste Lösung.

Abschluss

LED-Hallenstrahler bieten eine intelligente Lösung für Industrie- und Gewerbeflächen. Sie senken den Energieverbrauch um bis zu 70 %, reduzieren die langfristigen Wartungskosten, sorgen für helles und gleichmäßiges Licht und gewährleisten ein sichereres Arbeitsumfeld. Ob Lagerhalle, Fabrik, Sporthalle oder Logistikzentrum – LED-Hallenstrahler bieten zuverlässige Leistung und eine lange Lebensdauer.

CeramicliteWir sind spezialisiert auf energieeffiziente Industriebeleuchtung und bieten maßgeschneiderte Beleuchtungskonzepte, die auf Ihre Raumaufteilung, Montagehöhe und Helligkeitsanforderungen abgestimmt sind. Unsere LED-Hallenleuchte HB01bietet eine hohe Lichtausbeute, ausgezeichnete Wärmeableitung, IP65-Schutz, 10 Jahre Garantie und optionale intelligente Steuerungssysteme.

Bereit für eine modernere Beleuchtung? Fordern Sie noch heute einen kostenlosen Beleuchtungsplan oder ein Angebot von Ceramiclite an.

Häufig gestellte Fragen

Frage 1: Wie viele Lumen benötige ich für ein Lager?

Das hängt von der Arbeitsumgebung und der Deckenhöhe ab. Allgemeine Lagerbereiche benötigen etwa 10.000–20.000 Lumen pro Leuchte , während Montage- oder Prüfbereiche 20.000–30.000 Lumen benötigen , um die Beleuchtungsstärke von 300–500 Lux zu erreichen.

Frage 2: Welche Montagehöhe eignet sich für LED-Hallenstrahler?

Hallenstrahler sind für Deckenhöhen über 6 Metern (20 Fuß) ausgelegt .

6–9 m (20–30 Fuß): 100–150-W-Leuchten

9–12 m (30–40 ft): 150W–200W Leuchten

Ab 12 m (40 Fuß): 200-W- bis 300-W-Leuchten mit engerem Abstrahlwinkel

Frage 3: Können LED-Hallenstrahler gedimmt oder mit Bewegungsmeldern verwendet werden?

Ja. Die meisten modernen LED-Hallenstrahler, darunter auch der HB01 von Ceramiclite, unterstützen 0–10-V- oder DALI-Dimmung , Bewegungsmelder und sogar intelligente Steuerung per App oder IoT-System, um den Stromverbrauch bei Abwesenheit zu reduzieren.

Frage 4: Wie lange ist die Lebensdauer von LED-Hallenstrahlern?

Hochwertige Leuchten erreichen je nach Wärmemanagement und Nutzung eine Lebensdauer von 50.000 bis 100.000 Stunden . Die Ceramiclite HB01 bietet bis zu 100.000 Stunden Lebensdauer mit 10 Jahren Garantie und reduziert so die Kosten für Austausch und Wartung.

Frage 5. Hochregallager vs. Niedrigregallager – wie wählt man das richtige aus?

Der Unterschied liegt hauptsächlich in der Montagehöhe und dem Abstrahlwinkel :

Niedrige Hallenstrahler: Für Deckenhöhen unter 6 Metern (20 Fuß) , breiterer Abstrahlwinkel.

Hochregalleuchten: Für Deckenhöhen über 6 Metern , höhere Wattzahl und fokussierte Lichtverteilung.

Die Auswahl erfolgt anhand der Deckenhöhe, der benötigten Helligkeit und des Anwendungsbereichs.

_thumb.jpg)