Flicker-Free LED Lights: Everything You Need to Know

Table of Contents

What is Flicker? (Defining the Basics)

Why Do Lights Flicker? (Problems & Solutions)

The Hidden Dangers: Why Should You Care?

How to Measure Flicker: Moving Beyond the Basics

What Are Flicker Free LED Lights?

When you are selecting lighting fixtures for a dairy barn, a sports arena, or an industrial warehouse, you likely focus on lumens, wattage, or color temperature. But is flicker on your checklist? If not, it is time to take a closer look at how light stability impacts your environment.

There is a common misconception that LEDs are the only light sources that create unpleasant strobe-like effects. The reality is more complex. While it is true that LEDs can flicker, so does almost every other electric light source, including halogens, metal halides, and fluorescent tubes.

The difference lies in why they flicker and how we can fix it. Here are the facts about what flicker actually is, why it happens, and how to choose flicker-free LED lights.

What is Flicker? (Defining the Basics)

To solve the problem, we first need to define it clearly.

The Definition

The Definition

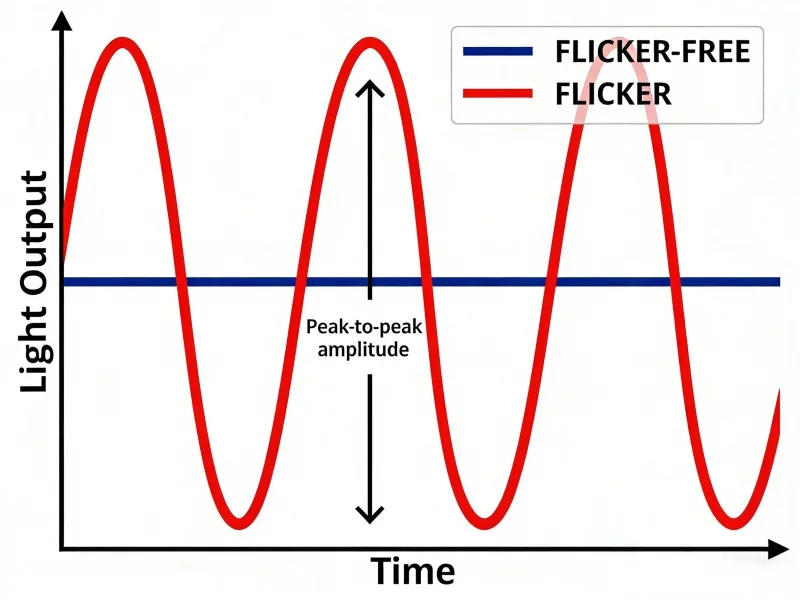

Flicker is the rapid on-off cycling of a light source.

Imagine a light switch being flipped on and off hundreds of times per second. That is essentially what is happening inside a flickering fixture. The light output is not a steady stream; instead, it fluctuates in intensity over time. While this can be intentional (like a strobe light in a nightclub), in professional settings, it is almost always an unwanted nuisance.

Two Types of Flicker

Flicker manifests in two distinct forms depending on its speed (frequency):

Ø Visible Flicker (<100 Hz):

This type occurs slowly enough—usually 100 times a second or less—that your eyes can directly detect the flashing. It is immediately noticeable and distracting.

Ø Invisible Flicker (>100 Hz):

This occurs when the light cycles so fast that your eyes cannot consciously see the flashing. However, just because you cannot see it does not mean it is harmless. Your brain and body still process these rapid changes, which can lead to negative effects such as headaches, eyestrain, and reduced concentration. In industrial environments, this invisible flicker causes the stroboscopic effect, making moving machinery appear dangerous still.

What Does "Flicker-Free" Actually Mean?

You will often see the term "flicker-free" on product packaging, but what does it technically mean?

Flicker-free LED lights are a kind of LED fixture engineered with a specific goal: to minimize current fluctuation to a level where it creates no perceptible effect on human health, livestock behavior, or camera equipment. It achieves this not by magic, but by using a high-quality driver that converts unstable AC power into a smooth, constant stream of DC energy.

Reference: https://en.wikipedia.org/wiki/Flicker_(light)

Pro Tip: Flicker vs. Glare – What’s the Difference?

Do not confuse these two visual hazards.

l Flicker happens in Time: It is the rapid fluctuation of light brightness (on/off cycling). It causes neurological stress.

l Glare happens in Space: It is excessive brightness or contrast that creates visual discomfort (like looking directly at the sun). Want to solve this? Read our guide on how to reduce glare in sports lighting.

Ceramiclite Solution: Our high-quality drivers eliminate flicker, while our advanced optical lenses minimize glare. You need both for a safe environment.

Why Do Lights Flicker? (Problems & Solutions)

An oft-repeated myth is that "LEDs just flicker naturally." That is false. LEDs themselves are stable; the problem lies in how we power them and how we control them.

Here are the two main causes of flicker and how to fix them.

Cause #1: The AC Power Supply

The Problem: Alternating Current (AC)

Most of the world’s electricity is delivered as Alternating Current (AC).

l The Wave: AC power flows in a wave (Sine wave), changing direction 50 to 60 times a second (50-60Hz).

l The Gap: Every time the current reverses direction, the voltage drops to zero.

l The Result: When the voltage hits zero, the light loses power for a fraction of a second.

Note: Old incandescent bulbs didn't flicker much because their hot filaments kept glowing during these gaps. LEDs, however, respond instantly. If the power cuts for a millisecond, the LED goes dark for a millisecond. This creates a rapid strobing effect.

The Solution: High-Quality Drivers (AC to DC Conversion)

You cannot change the power grid, but you can change how your light receives power. The solution is the LED Driver.

What it does: The driver acts like a bridge. It takes the "wavy" AC power and converts it into "flat" Direct Current (DC).

Quality Matters:

l Cheap Drivers: They do a poor job of smoothing out the wave, letting the "ripple" pass through to the LED. Result: Flicker.

l Ceramiclite Drivers: We use high-quality components (like capacitors) that act like a reservoir, filling in the power gaps. This ensures the LED receives a constant, steady current. Steady Current = No Flicker.

Cause #2: Improper Dimming

The Problem: Old Dimmers on New Lights

Flicker often happens when you try to dim an LED using technology built for the 1980s.

l Phase Cutting (TRIAC): Traditional wall dimmers work by "chopping" the AC sine wave, effectively turning the power off for longer periods to reduce brightness.

l The Conflict: While incandescent bulbs tolerated this well, LED electronics often struggle with chopped power waves. This mismatch causes the LED to behave erratically, leading to visible buzzing or flashing.

The Solution: Modern Dimming Protocols

To achieve flicker-free dimming, you need to upgrade the control system.

l 0-10V or DALI Systems: Instead of chopping the power wire, these systems use a separate signal to tell the driver exactly how bright to be. The driver then adjusts the current smoothly without creating the violent on/off gaps of old dimmers.

Summary: If your LEDs are flickering, it is likely due to a cheap driver failing to convert AC power, or an incompatible dimmer chopping the signal. The solution is always high-quality, purpose-built electronics.

The Hidden Dangers: Why Should You Care?

You might think, "If I can't see the flicker, does it really matter?"

The answer is a resounding yes. Even when light fluctuation is too fast for your eyes to register consciously, it still impacts biological systems and electronic equipment.

Here is how poor lighting quality translates into real-world risks for health, safety, and animal welfare.

Human Health: The Biological Toll

Your eyes might not "see" the flashing, but your brain certainly processes it.

When you work under flickering lights, your iris muscles are constantly expanding and contracting to adjust to the changing brightness. Simultaneously, your brain is working overtime to stitch these rapid flashes into a stable image.

This continuous neurological effort leads to health effects of lighting flicker, including:

l Eye Strain & Fatigue: A feeling of "heaviness" in the eyes after just a few hours.

l Headaches & Migraines: For sensitive individuals, flicker is a known trigger for severe migraines.

l Reduced Concentration: In offices or schools, this subtle stressor lowers cognitive performance.

Livestock Welfare: The "Disco Effect" on Animals

If you manage a farm, this is critical: Animals see light differently than humans.

Poultry, for example, have a much higher "Critical Flicker Fusion" (CFF) rate than people. While a light might look steady to you, it could look like a terrifying strobe light to a chicken or turkey.

Poor lighting stability hits your farm in two specific ways:

l For Poultry (Chickens/Turkeys):

Since they are highly sensitive to flicker, the constant visual stress leads to increased cortisol levels. This manifests as agitated behavior (pecking and cannibalism) and, ultimately, a drop in egg production or growth rates.

l For Dairy Cows:

Cows rely on regulated light cycles to manage melatonin and prolactin levels. Inconsistent flickering light can disrupt these hormonal rhythms, directly preventing the herd from achieving optimal milk yield.

The Bottom Line: For livestock lighting, "flicker-free" isn't just a luxury feature; it is an animal welfare standard that directly safeguards your production ROI.

Industrial Safety: The Stroboscopic Effect

In manufacturing environments, flicker is a physical danger.

This comes from the Stroboscopic Effect. Imagine a circular saw or a cooling fan spinning at high speed. If the LED light flickers at a frequency that matches the machine’s rotation speed, the blade will appear to be standing still.

This optical illusion creates a severe safety hazard. A worker might accidentally touch a moving machine they believe is off. For this reason, stroboscopic effect safety is a non-negotiable requirement in industrial lighting design.

Technology Interference: The Digital Disruption

Flicker is also the enemy of modern technology.

l Cameras: High-definition security cameras and sports broadcasting equipment capture images at high frame rates. Under flickering lights, your video feed will show distracting camera banding lines, ruining the broadcast quality in professional sports arenas.

l Scanners: In logistics, automated barcode scanners may fail to read labels if the light pulses during the scan, slowing down supply chains.

How to Measure Flicker: Moving Beyond the Basics

To truly evaluate safety, we cannot simply ask "does it flicker?" We must quantify how it flickers. A successful measurement must account for three critical characteristics:

1. Magnitude: How much does the light intensity change?

2. Frequency: How fast does it happen?

3. Waveform: What is the shape of the on/off cycle?

Here is the technical evolution of flicker metrics, from basic amplitude calculations to advanced frequency-domain analysis.

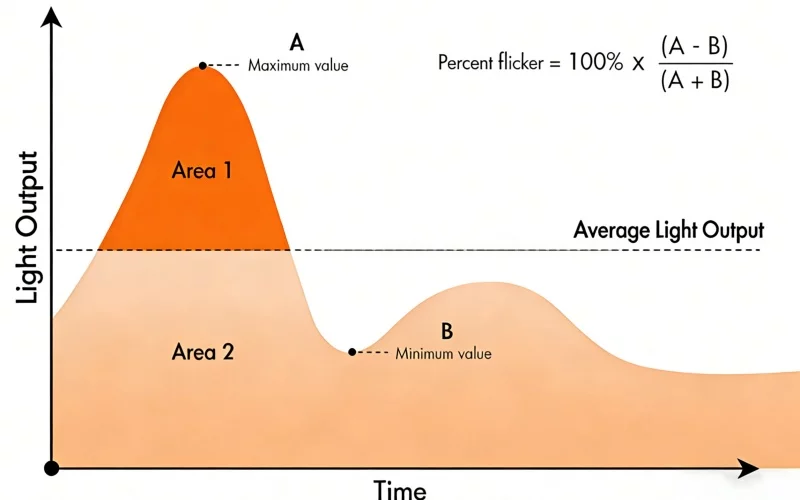

Method 1: Percent Flicker (Measuring Magnitude)

Likely the easiest metric to understand, Percent Flicker measures the magnitude (depth) of the modulation. It is strictly an amplitude calculation.

How it is calculated:

It takes the difference between the maximum light output (Peak) and the minimum light output (Trough), divided by the sum of those two values.

Percent Flicker=Max−MinMax+Min×100%Percent Flicker=Max+MinMax−Min×100%

The Scale:

0%: A perfectly steady light.

100%: The light turns completely OFF and then ON (like a strobe).

The Critical Limitation:

While easy to calculate, Percent Flicker completely ignores frequency and waveform.

Why this matters: A light with 100% flicker at 50Hz is a visual disaster. A light with 100% flicker at 10,000Hz (common in high-frequency PWM) is usually invisible and safe. Relying solely on Percent Flicker can accidentally disqualify suitable high-tech fixtures while failing to catch harmful low-frequency lights.

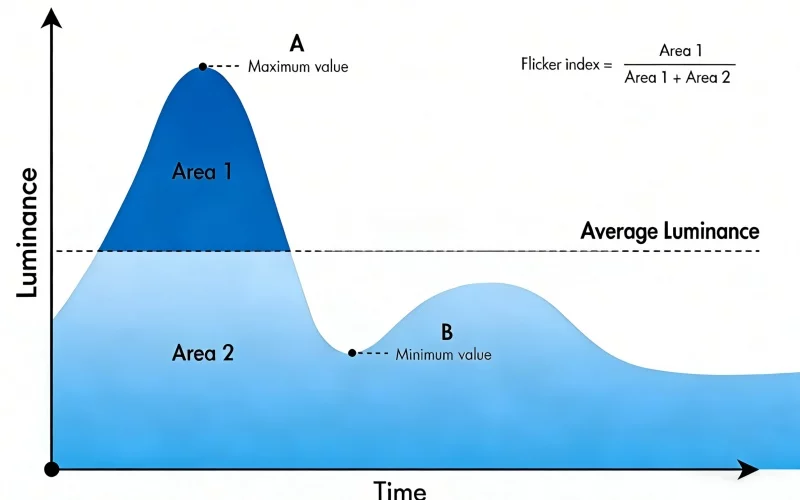

Method 2: Flicker Index (Measuring Waveform)

Flicker Index is a step up. Instead of just looking at the high and low points, it looks at the shape of the light output curve.

How it is calculated:

It measures the area under the light output waveform. Specifically, it divides the Area above the average light output by the Total area of the light output curve.

The Scale:

Ranges from 0 to 1 (lower is better).

Why it is better:

It accounts for the Duty Cycle (the percentage of time the light is effectively "on"). Two lights might have the same Percent Flicker, but if one stays "off" for longer periods during each cycle, it will have a worse (higher) Flicker Index. This makes it a more accurate representation of light stability than percentage alone.

Method 3: Frequency-Domain Analysis (The "Perception" Standards)

The latest and most accurate techniques—such as SVM and IEEE 1789—move beyond simple time-based measurements. They use Frequency-Domain Analysis.

l The Science (Fourier Transform):

These metrics rely on a mathematical process called a Fourier Transform. This converts the light signal from the "Time Domain" into the "Frequency Domain," breaking complex light signals into their fundamental frequency building blocks.

l Why this is the Gold Standard:

Unlike the previous methods, this approach accounts for Human Perception. It compares the light's frequencies against empirical data on how human eyes and brains actually react. It weights the data: lower frequencies (which hurt us more) are penalized heavily, while ultra-high frequencies are penalized less.

Key Standards Using This Method:

1. IEEE Std 1789-2015 (The Safety Guide)

The Institute of Electrical and Electronics Engineers (IEEE) combined biology and physics to create a definitive safety chart. It expands the analysis range up to 3000Hz to account for biological effects.

It defines three zones:

ü The No-Effect Region (Green): Safe for all applications.

ü The Low-Risk Region (Yellow): Acceptable for general use.

ü The High-Risk Region (White): Unsafe for industrial or biological environments.

2. SVM (Stroboscopic Visibility Measure)

This metric specifically evaluates the Stroboscopic Effect—the danger of moving objects appearing still. It focuses on frequencies >80Hz.

Target: SVM should be ≤ 1.0. For high-precision industrial tasks, you want this value closer to 0.

Recommended Table: Key Flicker Metrics Comparison

Metric | What It Measures | Pros | Cons | Verdict |

Percent Flicker (PF) | The difference between max & min brightness (0-100%). | Easy to calculate and understand. | Ignores frequency. Fails to detect high-speed invisible flicker. | Outdated. Only useful for basic checks. |

Flicker Index (FI) | The shape and duty cycle of the light waveform (0-1.0). | More accurate than PF; considers the "off" time. | Still doesn't fully account for human perception frequencies. | Better, but not complete. |

SVM (Stroboscopic Visibility Measure) | The visibility of strobe effects in moving environments. | The Gold Standard. Accounts for human sensitivity and speed. | Requires professional equipment to measure. | Essential for Industrial & Sports safety. |

Pst LM (Short Term) | Visible flicker perception over a short period. | Excellent for detecting visible (<80Hz) nuisance flicker. | Complex calculation; less focused on high-speed machinery. | Standard for Office & General lighting. |

How to Check Your Lights?

You likely do not have a $2,000 spectral light meter sitting in your pocket. Fortunately, you already own a device that can perform a basic check: your smartphone.

Here is a simple way to screen for bad lighting.

The Smartphone Trick (Slow-Motion Video)

Modern smartphone cameras capture video at high frame rates (often 240 frames per second or higher). This makes them excellent tools for detecting light flicker that is invisible to the naked eye.

How to test led flicker with phone:

1. Open your camera app and switch to "Slow-Motion" (Slo-Mo) video mode.

2. Point the camera directly at the light source.

3. Record for about 5 seconds.

4. Play the video back.

What to look for:

If the light on your screen is strobing, flashing on and off, or has rolling dark bands moving across the image, your fixture has significant flicker issues. If the image remains solid and steady, the light is relatively stable.

A Critical Note: Qualitative vs. Quantitative

While this phone trick is useful, it has limitations. It is a qualitative test—it tells you if a problem exists, but not how severe it is.

l What it tells you: "Yes, this light is flickering."

l What it misses: It cannot measure the specific Flicker Index, the frequency (Hz), or whether it falls into the IEEE 1789 "safe zone."

For professional audits—especially in industrial or livestock settings—you should always verify results with a professional Light Meter or Spectrometer.

What Are Flicker Free LED Lights?

If you browse the market, you will see thousands of products labeled "Flicker-Free." But be careful: marketing labels can be deceiving.

The Myth vs. The Reality

Many manufacturers claim a light is "flicker-free" simply because the flicker is faster than 100Hz (invisible to the human eye). As we learned earlier, this is not enough for industrial safety or animal welfare.

The Reality: A truly flicker-free light relies entirely on the heart of the fixture—The Driver.

The Technology Behind Ceramiclite

At Ceramiclite, we do not just aim to trick the human eye. We engineer our lights to meet the strictest physical standards. Here is how we do it:

l High-Quality Constant Current Drivers:

Cheap lights use simple rectifiers that let the AC power ripple through. We use advanced drivers with large capacitance and complex circuitry. This technology acts like a dam, smoothing out the turbulent AC power into a perfectly flat, Constant Current stream. No ripple means no flicker.

l High-Frequency PWM (If Dimming is Needed):

When digital dimming is required, we ensure the switching speed is incredibly fast. While standard lights might switch at 300Hz, high-end industrial systems can operate at frequencies above 2000Hz. At this speed, the flicker is biologically and mechanically irrelevant.

Our Commitment

We believe in data, not buzzwords. Ceramiclite is committed to delivering lighting solutions that go beyond basic compliance. We aim for a Percent Flicker rate of <5% (often <1%) and strictly adhere to the safety zones defined by the IEEE 1789 standard.

Conclusion

Lighting is often an afterthought, but it shouldn't be.

Saving a small amount of money on LED fixtures with cheap drivers is a false economy. The hidden costs—whether it is compromised worker safety, reduced milk yield in your dairy barn, or poor video quality in your arena—far outweigh the initial savings.

Flicker-free LED lights are an investment in safety, productivity, and welfare.

Ready to Upgrade?

Do not guess about your lighting quality. If you are looking for a verified, high-performance solution for industrial, sports, or livestock applications, let’s talk.

Consult with a Ceramiclite engineer today to design a lighting plan that is safe for your team, your animals, and your business.

_thumb.jpg)