Industrielle LED-Hallenbeleuchtung: Ein vollständiger Leitfaden

Große Räume erfordern eine hohe Beleuchtungsleistung – und genau da kommt die industrielle LED-Hallenbeleuchtung ins Spiel.

Falls Sie sich jemals gefragt haben, wie man eine riesige Industriehalle beleuchten kann, ohne Energie oder Geld zu verschwenden, führt Sie dieser Leitfaden durch alles, was Sie wissen müssen.

Inhaltsverzeichnis

Was ist industrielle LED-Hallenbeleuchtung?

Hochregal- vs. Niedrigregalbeleuchtung – Die wichtigsten Unterschiede

Arten von industriellen LED-Hallenstrahlern

Wo werden LED-Hallenstrahler eingesetzt?

Die 3 wichtigsten Vorteile von industriellen LED-Hallenstrahlern

Wie hoch ist der ROI von industriellen LED-Hallenbeleuchtungen?

Wie plant man die Anordnung der hohen Regale?

Was ist industrielle LED-Hallenbeleuchtung?

Industrielle LED-Hallenbeleuchtung klingt zwar komplex, ist aber im Prinzip ganz einfach: Sie ist für hohe Räume konzipiert, in denen herkömmliche Lampen nicht ausreichen. Denken Sie an Orte wie Fabriken, Lagerhallen oder Flugzeughangars mit Deckenhöhen von über sechs Metern.

Bei so großer Entfernung zum Dach benötigt man starkes, fokussiertes Licht, das tatsächlich bis zum Boden reicht. Genau dafür sind Hallenstrahler konzipiert.

Früher waren herkömmliche Optionen wie Metallhalogenid- oder Leuchtstoffröhren die erste Wahl, aber seien wir ehrlich – sie werden heiß, verbrauchen viel Strom und brennen gerne im ungünstigsten Moment durch .

Industrielle LED-LeuchtenDrehen wir die Sache um . Sie liefern die gleiche (oder sogar eine bessere) Helligkeit bei etwa halbem Energieverbrauch und können 50.000 Stunden oder länger leuchten, bevor man überhaupt an Wartung denken muss.

Kurz gesagt: Sie sind die intelligentere, robustere und effizientere Lösung für die Beleuchtung großer Industriehallen. Mit dem richtigen Hallenbeleuchtungssystem lässt sich eine dunkle, schattige Lagerhalle in einen hellen, sicheren und energiesparenden Arbeitsplatz verwandeln.

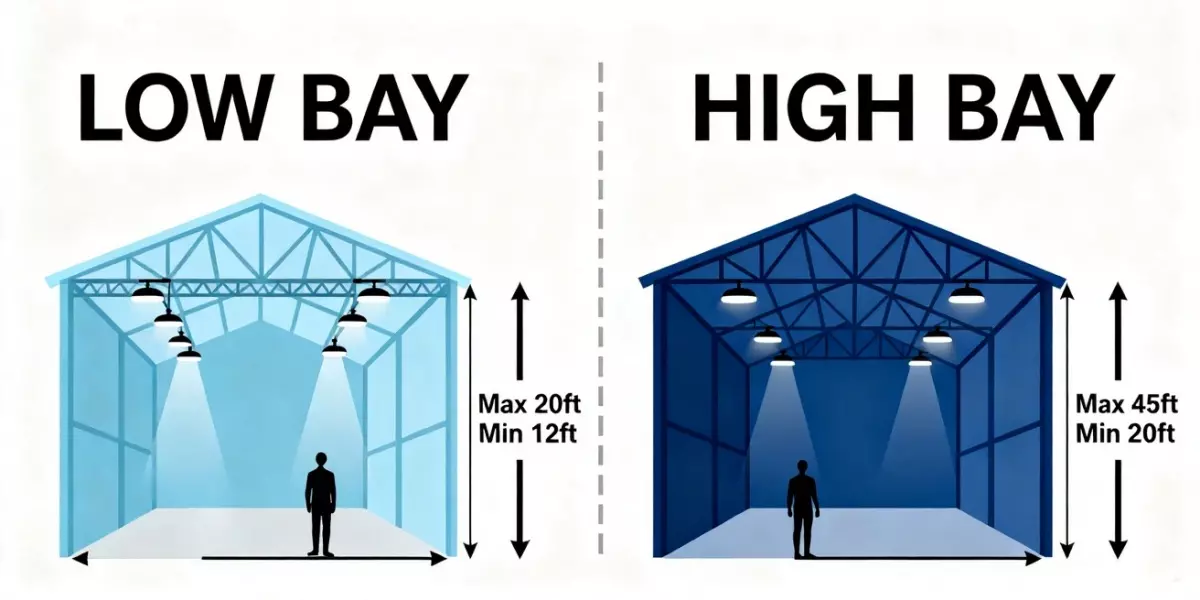

Hochregal- vs. Niedrigregalbeleuchtung – Die wichtigsten Unterschiede

Sind Sie schon einmal in zwei verschiedene Fabriken gegangen und haben bemerkt, dass die eine hell und sonnig wirkt, während die andere gleichmäßig, aber etwas gedämpfter ausgeleuchtet ist? Dieser Unterschied liegt oft an der Beleuchtung – ob mit hoher oder niedriger Deckenhöhe . Diese beiden Systeme sind für ganz unterschiedliche Deckenhöhen und Beleuchtungsanforderungen konzipiert.

Hallenstrahler sind für hohe Räume konzipiert – in der Regel ab 6 Metern Höhe –, in denen das Licht eine größere Entfernung zurücklegen und gleichzeitig eine hohe Leuchtkraft aufweisen muss. Sie nutzen engere Abstrahlwinkel, um die Beleuchtung gezielt auf den Arbeitsbereich darunter auszurichten.

Niedrige Hallenstrahler eignen sich hingegen besser für Räume unter 6 Metern Höhe , da sie mit breiteren Abstrahlwinkeln das Licht gleichmäßig über kürzere Distanzen verteilen. Sie sind ideal für Werkstätten, Verkaufsflächen und Garagen, wo keine große Leuchtweite erforderlich ist.

Hier ist eine kurze Vergleichstabelle zur Verdeutlichung:

Besonderheit | Hochregalbeleuchtung | Hallenbeleuchtung |

Montagehöhe | Über 6 m (20 Fuß) | Unter 6 m (20 Fuß) |

Strahlwinkel | Schmal (60°–120°) | Breit (120°+) |

Anwendungen | Lagerhallen, Fabriken, Turnhallen, Hangars | Werkstätten, Garagen, Einzelhandelsgeschäfte, Flure |

Lichtverteilung | Fokussiert, hell, weniger Reflexionen | Sanftere, gleichmäßige Ausleuchtung |

Wartung | Schwerer zu erreichen, aber lange Lebensdauer | Leichter zu warten, häufiger ausgetauscht |

Kurz gesagt: Wählen Sie nach Höhe, nicht nach Form . Wenn Ihre Leuchten von einer hohen Decke herabreichen müssen, sind Hallenstrahler die bessere Wahl. Für kleinere Räume oder niedrigere Decken eignen sich LED-Hallenstrahler im Industriestil besser.

Arten von industriellen LED-Hallenstrahlern

Jeder Industrieraum hat seinen eigenen Charakter – manche sind lang und schmal wie ein Lagerhallengang, andere weitläufig und offen wie eine Fabrikhalle.

Deshalb gibt es LED-Hallenstrahler in drei Hauptausführungen: lineare Hallenstrahler , UFO-LED-Hallenstrahler und modulare Hallenstrahler . Jeder Typ eignet sich für unterschiedliche Arbeitsbereiche und Beleuchtungsziele.

Hier die Kurzübersicht:

Typ | Ideal für | Hauptmerkmale | Typisches Aussehen |

Lineare Hallenstrahler | Lagerhallen, Gänge, Produktionslinien | Gleichmäßige Lichtverteilung, ideal für lange, schmale Bereiche | Rechteckige oder streifenförmige Form |

UFO-LED-Hallenleuchten | Freiflächen – Fabriken, Turnhallen, Werkstätten | Kompakt, leistungsstark, einfach zu montieren | Rundes, scheibenförmiges Design |

Modulare Hallenleuchten | Große Industriegebiete, maßgeschneiderte Projekte | Einstellbare Module, skalierbare Helligkeit, einfache Wartung | Paneelartige Struktur |

Typ 1: Lineare Hallenstrahler

Lineare Hallenstrahler sind die ideale Lösung für Lagerhallen und Produktionsgänge . Ihr längliches, rechteckiges Gehäuse sorgt für eine gleichmäßige Ausleuchtung des gesamten Ganges – perfekt, wenn durchgehende Helligkeit benötigt wird. Sie fügen sich nahtlos zwischen Regalreihen ein und reduzieren Schatten, wodurch Ihr Arbeitsbereich sicher und augenschonend bleibt.

Typ 2: UFO-LED-Hallenstrahler

Kompakt, rund und robust – die UFO LED-Hallenstrahler sind ideal für offene Industriebereiche, in denen Höhe und Ausleuchtung entscheidend sind. Trotz ihrer geringen Stellfläche bieten sie eine beeindruckende Helligkeit und eine exzellente Lichtverteilung. Dank ihres Designs ist die Installation kinderleicht: einfach aufhängen, anschließen, fertig. Perfekt für Fabriken, Werkstätten und Sporthallen , die eine leistungsstarke und gleichmäßige Ausleuchtung benötigen.

Typ 3: Modulare Hallenstrahler

Für Projekte, die Flexibilität erfordern, sind modulare Hallenstrahler die praktische Lösung. Dank ihrer modularen Bauweise lassen sich mehrere LED-Panels für eine höhere Lichtleistung kombinieren oder die Abstrahlrichtung an die Gegebenheiten anpassen. Sie werden häufig in großen Industrieanlagen oder kundenspezifischen Beleuchtungssystemen eingesetzt , wo Leistung und Skalierbarkeit gleichermaßen wichtig sind.

Kurz gesagt: Lineare Leuchten sorgen für helle und gleichmäßige Gänge, UFO-Leuchten eignen sich ideal für offene Räume, und modulare Leuchten bieten Ihnen die volle Kontrolle.

Wo werden LED-Hallenstrahler eingesetzt?

Wo werden LED-Hallenleuchten eingesetzt? Wirklich glänzen? Überall dort, wo die Decke hoch ist, die Arbeit ernst genommen wird und die Beleuchtung nicht nachlässig sein darf.

Diese Leuchten sind die erste Wahl für Lagerhallen, Fabriken, Werkstätten, Turnhallen und sogar Flugzeughangars – im Grunde für jeden Raum, der eine helle, gleichmäßige Beleuchtung von oben benötigt.

In Lagerhallen und Logistikzentren muss die Beleuchtung tief zwischen die Regale reichen, ohne Schatten zu werfen. Lineare Hochregallager sind hierfür ideal – sie leuchten die langen Gänge gleichmäßig aus, sodass die Mitarbeiter jeden Barcode klar erkennen können.

In Fabriken und Produktionsstätten sind Helligkeit und Sicherheit von höchster Bedeutung. Maschinen, Werkzeuge und Mitarbeiter bewegen sich schnell, daher reduziert helles, gleichmäßiges Licht Unfälle und Augenbelastung. UFO- oder modulare Hallenstrahler bewältigen diese anspruchsvollen Aufgaben mühelos und sorgen für optimale Sicht und effizientes Arbeiten.

Die Beleuchtung von Werkstätten verdient besondere Beachtung. In diesen Bereichen sind klare Sicht und gezieltes Arbeiten unerlässlich – sei es in der Metallverarbeitung, der Autoreparatur oder bei Feinmontagearbeiten. LED-Hallenstrahler liefern die von den Mitarbeitern benötigte, gestochen scharfe und schattenfreie Sicht und bieten gleichzeitig eine exzellente Farbtreue zur Unterscheidung von Materialien und Oberflächen.

In Sporthallen und Turnhallen steht der Komfort im Vordergrund. Man wünscht sich viel Licht ohne Blendung, damit die Spieler den Ball und nicht die Sterne sehen. LED-Hallenstrahler bieten ein ausgewogenes Verhältnis von Intensität und Streuung und schaffen so eine helle, aber angenehme Atmosphäre.

Ganz gleich, wie groß der Raum ist, das richtige Leuchtendesign – linear für Gänge , UFO für offene Bereiche , modular für individuelle Anpassungen – sorgt dafür, dass Ihre Beleuchtung mehr leistet, als nur zu leuchten; sie arbeitet genauso hart wie Sie.

Die 3 wichtigsten Vorteile von industriellen LED-Hallenstrahlern

Warum ersetzen so viele Fabriken Metallhalogenid- oder Leuchtstofflampen durch LED-Hallenstrahler?

Es geht nicht nur darum, mit den technologischen Trends Schritt zu halten, sondern auch darum, besseres Licht zu geringeren Kosten zu erhalten. Industrielle LED-Hallenbeleuchtung vereint Effizienz, Zuverlässigkeit und Leistung in einem intelligenten System, das sich mit der Zeit amortisiert.

Vorteil 1 : Energieeffizienz und Stromeinsparung

Beginnen wir mit dem offensichtlichen Vorteil – den Energiekosten. LED-Hallenstrahler verbrauchen 60–70 % weniger Strom als Halogen-Metalldampflampen und rund 40 % weniger als Leuchtstoffröhren . Sie wandeln mehr Strom in Licht statt in Wärme um, was eine hellere Ausleuchtung ermöglicht, ohne dass sich Ihre Produktionshalle in einen Backofen verwandelt. Kurz gesagt: weniger Stromverbrauch, mehr Licht, niedrigere Kosten.

Vorteil 2 : Langlebigkeit und Wartung

Sie haben es satt, ständig Glühbirnen an einer 9 Meter hohen Decke zu wechseln? LEDs sind die Lösung. Mit einer Lebensdauer von 50.000 bis 100.000 Stunden halten sie fünf- bis zehnmal länger als Metallhalogenlampen. Das bedeutet weniger Lampenwechsel, weniger Ausfallzeiten und zufriedenere Wartungsteams. Industriehallen und Fabriken schätzen diese Zuverlässigkeit.

Vorteil 3 : Lichtqualität und Leistung

LED-Hallenstrahler glänzen auch (buchstäblich) in puncto Lichtqualität. Sie liefern einen hohen Farbwiedergabeindex (CRI 80+) und sorgen so für eine natürliche, präzise Farbwiedergabe, die die Augenbelastung reduziert. Keine Aufwärmzeit, kein Flimmern – einfach nur klares, gleichmäßiges Licht vom ersten Moment an.

Kein Flackern, kein Warten, kein Drama – nur sauberes, gleichmäßiges Licht.

Kurzer Vergleich: LED-Beleuchtung vs. herkömmliche Beleuchtung

Besonderheit | LED-Hallenbeleuchtung | Metallhalogenid | Fluoreszierend |

Energieeffizienz | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

Lebensdauer | 50.000–100.000 Stunden | 10.000 Stunden | 15.000–20.000 Stunden |

Aufwärmzeit | Sofort | 5–10 Minuten | Sofort |

CRI | 80+ | 65–70 | 75 |

Wartung | Niedrig | Hoch | Medium |

LED-Hallenstrahler sind nicht einfach nur Ersatz – sie sind eine Modernisierung, die die Beleuchtung von Industrieräumen neu definiert.

Wie hoch ist der ROI von industriellen LED-Hallenbeleuchtungen?

Die Umstellung auf industrielle LED-Hallenbeleuchtung ist nicht nur eine Modernisierung der Beleuchtung – sie ist eine kluge Geschäftsentscheidung. Viele Facility Manager stellen sich zunächst die einfache Frage: „Lohnt sich das wirklich?“ Die kurze Antwort? Ja – und in der Regel schneller als erwartet.

Energieeinsparungen, die sich schnell summieren

Die Energiekosten machen den größten Teil jedes Beleuchtungsbudgets aus. LED-Hallenstrahler verbrauchen 50–70 % weniger Strom als Halogen-Metalldampflampen und etwa 40 % weniger als Leuchtstoffröhren . Für ein Lager mit 100 Leuchten à 400 W ergibt das eine jährliche Ersparnis von rund 10.000–15.000 US-Dollar (abhängig von den örtlichen Tarifen und Betriebszeiten).

Weniger Stromverbrauch, weniger Wärmeentwicklung – Ihre Stromrechnung für Beleuchtung (und Klimaanlage) sinkt.

Tipp: Informieren Sie sich über die Förderprogramme Ihres Energieversorgers – viele bieten finanzielle Anreize für die Umrüstung auf LED-Systeme.

Längere Lebensdauer, geringerer Wartungsaufwand

Ein weiterer, oft übersehener Vorteil ist der geringe Wartungsaufwand. LED-Hallenstrahler haben typischerweise eine Lebensdauer von 50.000 bis 100.000 Stunden , sodass ein Austausch erst nach 8 bis 10 Jahren erforderlich ist . Im Vergleich dazu müssen Metallhalogenidlampen alle 1 bis 2 Jahre ausgetauscht werden.

Das bedeutet weniger Hebebühnen, weniger Leitern und weniger Produktionsunterbrechungen. Und in industriellen Umgebungen bedeutet jede eingesparte Wartungsstunde eine Stunde Arbeit, die nicht verloren geht.

Realistische Amortisationszeit: 3–5 Jahre

In den meisten industriellen Anwendungen amortisiert sich die Investition in LED-Umrüstungen innerhalb von 3 bis 5 Jahren . Danach stellen die Energie- und Wartungseinsparungen reinen Gewinn dar.

Eine Einrichtung, die beispielsweise jährlich 20.000 US-Dollar für Beleuchtung ausgibt, kann ihre Kosten nach dem Umstieg auf LED auf rund 7.000 US-Dollar senken – eine jährliche Ersparnis von 13.000 US-Dollar. Hochgerechnet auf fünf Jahre sprechen die Zahlen für sich.

ROI jenseits der Tabellenkalkulation

Natürlich ist der finanzielle Aspekt großartig – aber LEDs verbessern auch die Lichtqualität, die Arbeitssicherheit und den Komfort , was indirekt die Produktivität steigern kann. Besseres Licht bedeutet weniger Fehler und zufriedenere Mitarbeiter.

Kurz gesagt: Industrielle LED-Hallenbeleuchtung ist keine Ausgabe, sondern eine Investition, die sich mit jedem einzelnen hell erleuchteten Arbeitsplatz auszahlt .

Wie plant man die Anordnung der hohen Regalböden ?

Bei der richtigen industriellen LED-Beleuchtung geht es nicht nur darum, die beste Leuchte auszuwählen, sondern auch darum, die Anordnung der Leuchten optimal zu planen . Zwei Aspekte – Anzahl und Helligkeit – sind dabei entscheidend für ein gelungenes Beleuchtungskonzept.

Lassen Sie uns gemeinsam herausfinden, wie Sie beides richtig machen, ohne Ihre Fabrikhalle in eine Rampenlichtbühne oder eine Höhle zu verwandeln.

Schritt 1: Messen Sie Ihren Raum aus

Bevor Sie mit den Berechnungen beginnen, sollten Sie zunächst die Grundlagen erledigen: Messen Sie Ihren Raum aus. Sie benötigen:

Fläche: in Quadratmetern oder Quadratfuß

Deckenhöhe: Je höher die Decke, desto stärker müssen die Lampen sein.

Oberflächenreflexion: Helle Wände reflektieren Licht besser als dunkle.

Zweck: Produktionslinien, Lagerhallen oder Inspektionszonen benötigen jeweils unterschiedliche Helligkeitsstufen.

Eine Lagerhalle und ein Fitnessstudio mögen die gleiche Größe haben – aber sie benötigen definitiv nicht die gleiche Beleuchtungsstärke.

Schritt 2: Lampenmenge schätzen

Sobald Sie Ihre Maße haben, können Sie auf diese Weise schnell abschätzen, wie viele Leuchten Sie benötigen.

Eine allgemeine Formel lautet wie folgt:

Anzahl der Leuchten ≈ (Ziel-Lux × Fläche) ÷ (Lumen pro Leuchte × Nutzungsfaktor)

Angenommen, Sie haben ein 1.000 m² großes Lager , streben eine Beleuchtungsstärke von 300 Lux an und verwenden 26.000 Lumen starke Hallenstrahler. Für eine gleichmäßige Ausleuchtung benötigen Sie etwa 12–14 Leuchten .

Professionelle Lichtplanungssoftware wie Dialux oder Relux liefert natürlich präzisere Ergebnisse, aber diese einfache Überschlagsrechnung bietet einen soliden Ausgangspunkt für die Budgetplanung.

Schritt 3: Wählen Sie die richtige Helligkeit (Lumen-Tabelle für Hallenstrahler)

Hier ist eine einfache Referenztabelle, die Ihnen hilft, die ideale Lichtleistung für Ihre Deckenhöhe zu ermitteln:

Montagehöhe | Empfohlene Lumen pro Leuchte | Typische Anwendung |

20–30 Fuß | 22.000–35.000 lm | Lagerhalle, Werkstatt |

31–40 Fuß | 35.000–47.000 lm | Fabrik, Turnhalle, Hangar |

über 40 Fuß | 47.000+ lm | Schwerindustrie, Flugzeughallen |

Die Logik ist einfach: Je höher die Decke, desto leistungsstärker die Leuchte. Ist sie zu dunkel, entstehen dunkle Ecken und Sicherheitsrisiken. Ist sie zu hell, verschwendet man Strom und Geld. Die richtige Balance ist entscheidend.

Schritt 4: Feinabstimmung für optimale Effizienz

Sobald Sie die Grundlagen beherrschen, optimieren Sie mit dem richtigen Abstrahlwinkel und Layoutmuster :

Breiter Abstrahlwinkel (120°): besser geeignet für niedrige Decken und offene Bereiche

Schmaler Abstrahlwinkel (60°–90°): Ideal für hohe Decken oder gezielte Beleuchtungsbereiche

Betrachten Sie es als eine Art Lichtchoreografie – die richtige Platzierung sorgt dafür, dass jede Ecke ausgeleuchtet ist, ohne Ihre Stromrechnung in die Höhe zu treiben.

Abschluss

Industrielle LED-Hallenbeleuchtung bietet mehr als nur Helligkeit – sie zeichnet sich durch Effizienz, Sicherheit und einen hohen ROI aus. Durch den Umstieg auf LEDs senken Fabriken und Lagerhallen ihre Energiekosten, reduzieren den Wartungsaufwand und schaffen einen sichereren und helleren Arbeitsplatz für viele Jahre.

Bereit für den nächsten Schritt?

Entdecken Sie die LED-Hallenstrahler HB01 von Ceramiclite, die für jede industrielle Umgebung geeignet sind, oder kontaktieren Sie unsere Experten für eine kostenlose Lichtanalyse. um zu sehen, wie viel Sie sparen könnten.

Häufig gestellte Fragen

Frage 1: Können LED-Hallenstrahler im Außenbereich eingesetzt werden?

Ja – sofern sie mindestens die Schutzart IP65 aufweisen . Diese Schutzart bedeutet, dass sie staubdicht und wetterfest genug für Außen- oder halboffene Bereiche wie Laderampen oder überdachte Stadien sind. Stellen Sie eine Leuchte für den Innenbereich nicht einfach in den Regen und erwarten Sie, dass sie das problemlos übersteht.

Frage 2: Sind LED-Hallenstrahler dimmbar für eine flexible Lichtsteuerung?

Absolut. Viele Ceramiclite-Modelle unterstützen 0–10-V-Dimmung oder intelligente Steuerung , sodass Sie die Helligkeit je nach Aufgabe oder Tageslicht anpassen können. Das ist nicht nur praktisch, sondern spart auch Energie und verlängert die Lebensdauer der Lampe. Stellen Sie sich vor, Sie schaffen in Ihrer Fabrik eine individuelle Stimmungsbeleuchtung (allerdings für Produktivität, nicht für Romantik).

Frage 3: Welche Garantien bietet Ceramiclite für seine Hallenstrahler?

Die meisten unserer Leuchten haben eine 8- jährige Garantie , die sowohl die Leistung als auch die Teile abdeckt. Denn Industriebeleuchtung ist keine kurzfristige Investition – und wir stehen hinter jedem einzelnen Lumen, das wir verkaufen.

Frage 4: Wie lange halten LED-Hallenstrahler?

Typischerweise 50.000 bis 100.000 Stunden , abhängig von Nutzung und Umgebungsbedingungen. Das entspricht etwa 10 Jahren zuverlässiger Beleuchtung – deutlich länger als bei Metallhalogen- oder Leuchtstofflampen. Kurz gesagt: Einmal installieren, jahrelang Ruhe haben.

Frage 5: Sind LED-Leuchten nur ein vorübergehender Trend?

Keineswegs. LEDs sind die Zukunft der Industriebeleuchtung – energieeffizient, smart-fähig und langlebig . Herkömmliche Glühbirnen hingegen verschwinden allmählich.

F6: Wie gehe ich beim Austausch alter Lampen vor?

Metallhalogen- und Leuchtstofflampen enthalten oft Materialien, die fachgerecht recycelt oder entsorgt werden müssen . Das Support-Team von Ceramiclite hilft Ihnen gerne, zertifizierte Recyclingunternehmen zu finden, damit Ihre Modernisierung sauber, sicher und vorschriftsmäßig abläuft.

_thumb.jpg)