Chicken Coop Light for Winter: For Peak Egg Production

Table of Contents

The Science: How Much Light Do Layers Actually Need?

Timing Strategy: Morning vs. Evening Supplementation

Choosing the Right Hardware: Spectrum, Flicker, and Durability

The "Dawn to Dusk" Protocol (Advanced Automation)

Installation & Safety: Preventing Fire Hazards

Introduction

For commercial poultry farms, winter isn't just a change of season; it's an economic challenge. The stark reality is that reduced daylight hours—often dipping below 12—can trigger a precipitous drop in egg production, sometimes plummeting by 30% to 50%. This isn't merely a matter of fewer eggs; it's a direct hit to your bottom line.

While winter presents specific challenges, maintaining a standardized chicken coop lighting system year-round is the foundation of a profitable poultry operation. Beyond simply illuminating feed, light plays a crucial biological role. It stimulates the pituitary gland, triggering the release of follicle-stimulating hormone (FSH) and luteinizing hormone (LH). These hormones are the engines of egg production in laying hens. Understanding this physiological mechanism is the first step toward mitigating winter losses.

In poultry management, consistency is paramount. Abrupt changes in lighting schedules can be more detrimental than no supplemental light at all. Such disruptions can induce stress and trigger molting—a natural process where hens cease laying to replace their feathers—further exacerbating production deficits during a time when profitability is already strained. A steady, predictable lighting program is not just best practice; it's an economic imperative.

This guide covers the critical pillars of a successful winter lighting program:

l Production Consistency: Precise photoperiod control to prevent hormonal drops.

l Flock Welfare: Mitigating stress and cannibalism through spectrum management.

l Operational Efficiency: Reducing labor costs with automated "dawn-to-dusk" protocols.

l Equipment Durability: Selecting IP-rated hardware built to withstand high-ammonia environments.

The Science: How Much Light Do Layers Actually Need?

To maintain consistent egg output throughout winter, a supplemental lighting program must adhere to precise scientific parameters. While natural daylight wanes, ensure your laying flock receives a consistent 14-16 hours of light per day. This extended photoperiod mimics the optimal conditions of spring and summer, sustaining hormonal activity and encouraging consistent laying patterns.

Beyond duration, light intensity is a critical factor often overlooked. While wattage is a common metric for household lighting, it's insufficient for poultry management. Instead, focus on Lux (lx) or Lumens (lm) to quantify the amount of light reaching the birds.

Ø Laying Area: Aim for 10-20 Lux at bird level in the primary laying areas. This provides sufficient illumination for foraging, drinking, and laying without causing undue stress.

Ø Nesting Boxes: Maintain dim conditions, less than 1 Lux, within nesting boxes. Hens prefer dark, secluded areas for laying, and excessively bright nesting boxes can lead to egg pecking and cannibalism.

Consider the size and layout of your coop when determining the number of light sources. As a general guideline, a forum contributor noted that "Coops up to 40 square feet are good with a 250 lumens bulb in the center." However, this should be translated into a more nuanced recommendation: Ensure even light distribution across the floor to prevent "hot spots" and shadows. Uneven lighting can lead to floor eggs, as hens seek out dimly lit areas to lay, resulting in lost or contaminated eggs.

By understanding and implementing these scientifically-backed lighting parameters, poultry farmers can effectively counteract the seasonal dip in egg production and maintain a profitable operation throughout the winter months.

Timing Strategy: Morning vs. Evening Supplementation

One of the most debated topics in poultry management is when to add the supplemental light. For commercial operations, the consensus is definitive: Follow the "Morning Rule."

Why Morning Supplementation is Superior:

1. Roosting Safety & Orientation: If you extend daylight into the evening, an abrupt shut-off (even with a timer) can leave hens stranded on the coop floor, unable to navigate back to their roosts in sudden darkness. This leads to increased stress, piling, and "floor eggs," which are often dirty and unsellable.

2. Natural Circadian Rhythm: By adding light in the pre-dawn hours, you simulate an earlier sunrise. The evening allows for a natural dusk (as the sun goes down), signaling the flock to settle, preen, and roost instinctively before total darkness falls.

Operational Recommendation:

Set your programmable timers to activate at 3:00 AM or 4:00 AM (depending on your latitude and total daylight target) and shut off once natural sunrise provides sufficient lux levels. This ensures the flock receives the required 14-16 hours of stimulation without disrupting their natural roosting behavior.

Choosing the Right Hardware: Spectrum, Flicker, and Durability

Not all light is created equal. Commercial poultry vision is significantly different from human vision, and selecting the wrong hardware can lead to behavioral issues and equipment failure.

1. The Science of Spectrum (Kelvin)

The color temperature of your lighting directly influences bird behavior and physiology:

Ø Warm White (2700K - 3000K): Recommended for Laying. This spectrum mimics natural sunlight and contains the red wavelengths crucial for penetrating the hen's skull to stimulate the pituitary gland (reproduction).

Ø Deep Red (Monochromatic): Effective for managing aggression. If cannibalism or feather pecking outbreaks occur, switching to red light can mask blood spots and calm the flock, though it may make inspection difficult.

Ø Cool White / Daylight (>5000K): Avoid. High blue content can increase bird activity to the point of nervousness and flightiness, leading to wasted energy and potential injury.

Choosing the correct spectrum is critical, as poultry lighting significantly influences not just egg count, but the overall growth and stress levels of your flock.

2. The Invisible Stressor: Light Flicker

A critical factor often overlooked is Flicker. Chickens possess a higher Critical Flicker Fusion (CFF) rate than humans. A standard LED that appears steady to the human eye may appear as a strobe light to a chicken.

l The Risk: Continuous "strobe" effects cause chronic stress, elevating cortisol levels and suppressing the immune system.

l The Solution: Utilize poultry-specific lighting with flicker-free drivers. CeramicLite fixtures for modern poultry farm are engineered to deliver constant current, ensuring a stable light output that supports flock welfare.

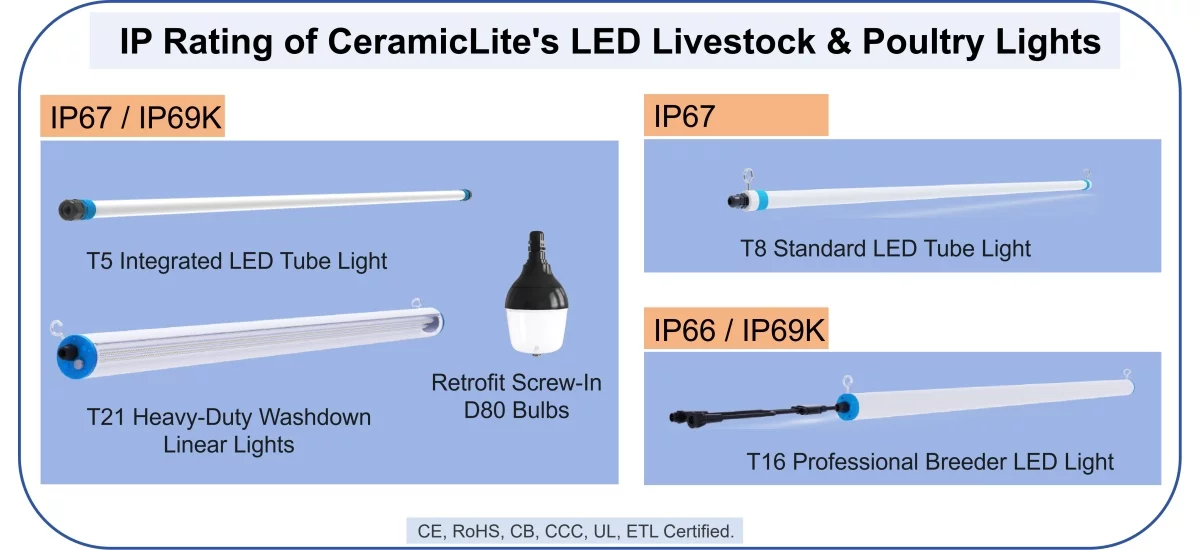

3. Engineering for Harsh Environments (IP Rating)

Poultry houses are hostile environments for electronics. High concentrations of ammonia, combined with dust and humidity, will corrode standard residential bulbs rapidly.

Requirement: Equipment must be rated IP65 or IP66.

CeramicLite Advantage: Ceramiclite is committed to crafting lighting fixtures that boast both exceptional durability and reliable practicality. Our fixtures are designed with corrosion-resistant materials and sealed specifically to withstand the caustic nature of poultry dust and ammonia, significantly reducing replacement costs and maintenance labor.

The "Dawn to Dusk" Protocol (Advanced Automation)

For larger facilities, simple on/off switching is outdated. Modern management utilizes dimmable controllers to execute a "Dawn to Dusk" protocol.

Why Simulate Transitions?

Abruptly switching lights on to full brightness (or off to total darkness) causes "lux shock."

l Heart Health: Sudden bright light can cause panic and cardiac stress in birds.

l Roosting Control: A gradual dimming in the evening allows birds to naturally move toward roosts before it becomes too dark to see.

Best Practice Setup:

Integrate your timers with a dimmer to create a 15-30 minute ramp-up (sunrise simulation) and ramp-down (sunset simulation) period. This gentle transition aligns with the biological expectations of the flock, maintaining a calm environment conducive to consistent production.

Installation & Safety: Preventing Fire Hazards

In the poultry industry, winter coop fires are a devastating reality, often caused by improper equipment. It is imperative to distinguish between heating and lighting.

The Heat Lamp Warning

We strictly advise against using traditional heat lamps (infrared bulbs with high heat output) solely for lighting purposes. As noted by industry leaders like Purina Animal Nutrition, adult chickens are cold-hardy, and heat lamps pose a severe fire risk due to the presence of dry bedding (dust/straw) and feathers. For commercial layers, light is for production; heat is rarely necessary once the flock is fully feathered.

The LED Safety Advantage

Unlike heat lamps that pose fire risks, high-quality LED barn lights convert energy efficiently into lumens rather than waste heat, making them the safest choice for dusty environments. LED technology is the standard for modern poultry operations because it produces "cold light". A high-quality LED fixture converts energy into lumens rather than waste heat, drastically reducing the risk of accidental ignition even if the fixture comes into contact with dust.

Strategic Layout for Flock Management

Installation is not just about hanging a bulb; it is about Light Uniformity.

Ø The Risk of Shadows: Dark corners encourage hens to lay eggs on the floor ("floor eggs"), which increases contamination rates and labor costs.

Ø The Risk of Bright Spots: Excessively bright distinct spots can cause "piling," where birds crowd together, leading to suffocation or overheating.

Ø Best Practice: Install lights at regular intervals (or use linear LED systems) to ensure an even lux level across the entire floor area.

Quick Troubleshooting: Winter Production Drops

If you have implemented a lighting program but are still seeing production issues, consult this diagnostic table.

Symptom | Probable Cause | Corrective Action |

Production stopped despite 14h light | Cold Stress or Protein Deficiency | Light stimulates the hormones, but the body needs fuel. Winter birds burn more calories staying warm. Increase feed protein levels and check for drafts. |

Cannibalism / Feather Pecking | Light Intensity Too High | If light exceeds 20-30 lux or is too "cool" (white/blue), birds become aggressive. Switch to warm white (2700K) or dim the lights. Red spectrum helps mask blood. |

High Number of Floor Eggs | Shadows in Corners | Hens seek dark places to lay. If corners of the coop are darker than the nest boxes, they will lay there. Add lighting to eliminate shadows or darken the nest boxes further. |

Molting in Mid-Winter | Inconsistent Light Cycle | Did a breaker trip? Did the timer drift? Even a few days of irregular light can trigger a molt. Check your backup power systems and timer settings immediately. |

Conclusion

Managing winter lighting is not merely an operational cost; it is one of the highest Return on Investment (ROI) strategies available to a poultry farm. A well-executed lighting program bridges the gap between the dark days of winter and the peak production of spring, ensuring your revenue stream remains consistent when market prices are often highest.

However, the effectiveness of this strategy relies on the reliability of your equipment. Cheap residential bulbs cannot withstand the ammonia, humidity, and dust of a poultry environment.

Ready to optimize your winter production?

Upgrade your facility with CeramicLite’s specialized poultry lighting solutions. Engineered for durability (IP66), tailored for poultry vision (Flicker-Free), and designed for safety, our lights ensure your flock performs at its peak, regardless of the season.

![]()

_thumb.jpg)