Halogénures métalliques contre LED : le duel d'éclairage 2026

Table des matières

Introduction : La fin d'une ère ?

Partie 1 : Définition des combattants

Partie 2 : Les données parlent d'elles-mêmes

Partie 3 : 13 raisons pour lesquelles les LED remportent la guerre

Partie 4 : La vérité, toute la vérité (Y a-t-il des inconvénients ?)

Partie 5 : De la théorie à la pratique

Partie 6 : La solution supérieure : Pourquoi Ceramiclite ?

Introduction : La fin d'une ère ?

Les lampes à halogénures métalliques sont-elles meilleures que les LED en 2026 ?

La réponse courte est non . Dans presque toutes les catégories mesurables — efficacité, longévité et contrôle — la technologie LED a remporté la victoire de façon décisive.

Cependant, si vous gérez une usine à haute température ou un grand complexe sportif, la réponse est plus nuancée. Bien que les LED soient plus performantes que l'éclairage traditionnel, elles ne répondent pas toutes aux mêmes normes . Remplacer un luminaire robuste à halogénures métalliques par une LED bon marché à lentille en plastique peut en réalité engendrer davantage de problèmes par la suite.

Nous comprenons vos difficultés. Outre des factures d'énergie exorbitantes, vous devez gérer le véritable casse-tête logistique de la maintenance. Chaque fois qu'une ampoule grille dans un entrepôt de 12 mètres de haut, vous ne payez pas seulement le remplacement de l'ampoule, mais aussi la location de la nacelle élévatrice , la main-d'œuvre et l'immobilisation de vos installations.

Voici la dure réalité : les lampes aux halogénures métalliques sont notoirement inefficaces pour maintenir leur luminosité, perdant jusqu’à 40 % de leurs lumens dès la première année.

Cela signifie que vous payez 100 % du coût énergétique pour seulement 60 % de la lumière.

Dans ce guide, nous n'allons pas nous contenter de comparer les deux technologies. Nous examinerons pourquoi les installations industrielles se précipitent pour moderniser leurs équipements et comment éviter les pièges courants liés au passage aux LED.

Partie 1 : Définition des combattants

Avant d'aborder les calculs de retour sur investissement et les graphiques de puissance, définissons brièvement ce que nous comparons. Comprendre les mécanismes est essentiel pour identifier les points de défaillance.

Qu'est-ce qu'une lampe à halogénures métalliques ? (The Old Guard)

Les lampes aux halogénures métalliques (MH) sont un type d'éclairage à décharge à haute intensité (HID). Pendant des décennies, elles ont dominé le marché de l'éclairage industriel.

Les lampes aux halogénures métalliques (MH) sont un type d'éclairage à décharge à haute intensité (HID). Pendant des décennies, elles ont dominé le marché de l'éclairage industriel.

Techniquement parlant, le procédé consiste à faire passer un arc électrique à travers un mélange de gaz (mercure et halogénures métalliques) à l'intérieur d'un tube de quartz. On peut l'imaginer comme un éclair contrôlé et continu, enfermé dans une bouteille.

L'analogie avec les « voitures musclées » :

On pourrait comparer une lampe aux halogénures métalliques de 1000 W à une vieille voiture de sport des années 1970, grande consommatrice d'essence.

Il est puissant : il produit une lumière blanche très vive et intense.

C'est inefficace : cela génère une quantité massive de chaleur gaspillée pour produire cette énergie .

l Son entretien est coûteux : tout comme un vieux moteur, les pièces s'usent rapidement et les performances diminuent considérablement avec le temps.

Longtemps, c'était la seule option pour les stades et les entrepôts. Mais aujourd'hui, son fonctionnement est tout simplement trop coûteux.

Qu'est-ce qu'une diode électroluminescente (DEL) ? (Le Challenger)

LED signifie diode électroluminescente . Contrairement aux lampes à halogénures métalliques, qui utilisent la combustion de gaz et des tubes de verre fragiles, les LED sont une forme d' éclairage à semi-conducteurs (SSL) .

LED signifie diode électroluminescente . Contrairement aux lampes à halogénures métalliques, qui utilisent la combustion de gaz et des tubes de verre fragiles, les LED sont une forme d' éclairage à semi-conducteurs (SSL) .

Elle génère de la lumière en faisant passer un courant électrique à travers un matériau semi-conducteur. Lorsque les électrons se déplacent, ils libèrent de l'énergie sous forme de photons (lumière).

La révolution numérique :

si les lampes à halogénures métalliques sont analogiques, les LED sont numériques.

Précision : Elle dirige la lumière exactement là où vous en avez besoin, au lieu de la diffuser à 360 degrés comme une ampoule .

l Efficacité : Elle convertit la grande majorité de l'énergie en lumière, et non en chaleur.

Durabilité : Il n'y a pas de filaments susceptibles de se casser ni d'ampoules en verre qui peuvent se briser.

Cependant, contrairement aux lampes à halogénures métalliques, les LED ne dégagent pas de chaleur, leurs composants électroniques internes chauffent. Et comme nous le verrons plus loin, la gestion de cette chaleur interne fait toute la différence entre une LED qui dure 10 ans et une autre qui tombe en panne en 10 mois.

Partie 2 : Les données parlent d'elles-mêmes

Les chiffres sont implacables. Lorsqu'on compare directement ces technologies, l'écart de performance devient indéniable.

Cependant, comme nous l'avons mentionné précédemment, toutes les LED ne sont pas adaptées à un usage industriel intensif.

Vous trouverez ci-dessous une comparaison entre la technologie traditionnelle (halogénures métalliques), la norme actuelle du marché (LED standard) et l'avenir de l'éclairage industriel (Ceramiclite FTC).

Tableau comparatif lampes à halogénures métalliques vs LED

Paramètre | Halogénure métallique (La vieille méthode) | LED standard (Silicone/Phosphore) | LED Ceramiclite FTC (La solution industrielle) |

Durée de vie (durée de vie utile) | 10 000 à 15 000 heures | ~50 000 heures (L70) | Plus de 100 000 heures (vérifié LM-80) |

Maintenance du lumen | Mauvais : Perd 40 % de luminosité la première année | Moyenne : Déclin progressif dû à la chaleur | Supérieur : <5 % de dégradation sur 100 000 heures |

Efficacité énergétique | 60 à 80 lumens/watt | 130 - 150 lumens/watt | 160 - 180 lumens/watt |

résistance chimique | Faible (Corrode) | Mauvais : Le silicone absorbe le soufre (noircissement) | Excellent : La céramique est imperméable. |

Temps de démarrage | 15 minutes (échauffement) | Instantanément activé | Instantanément activé |

Gestion de la chaleur | Rayonne une chaleur extrême | Piège la chaleur (barrière en silicone) | Conduit la chaleur (10 W/m·K) |

Troisième partie : Les raisons pour lesquelles les LED remportent la guerre

Bien qu’il existe des dizaines de raisons techniques de changer, elles se résument toutes à trois grandes catégories : l’argent, la performance et le contrôle .

Analysons en détail les « 13 raisons » et découvrons ces arguments essentiels pour comprendre pourquoi rester fidèle aux halogénures métalliques vous coûte plus cher que vous ne le pensez.

L'argument économique : retour sur investissement et économies

Pour la plupart des gestionnaires d'installations et des chefs d'entreprise, la décision de moderniser n'est pas une question de « technologie de pointe », mais de rentabilité.

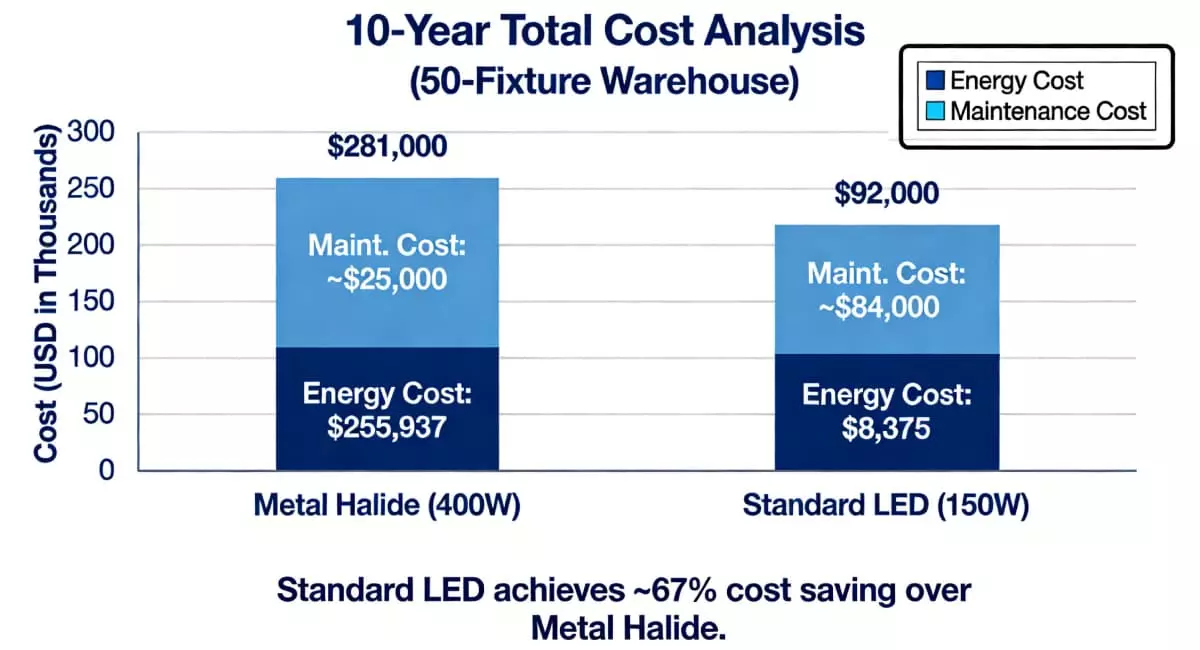

L'impact le plus immédiat du changement se fera sentir sur votre facture d'électricité mensuelle.

Les lampes à halogénures métalliques sont omnidirectionnelles, c'est-à-dire qu'elles diffusent la lumière dans toutes les directions (360 degrés). Pour diriger cette lumière vers le sol, là où elle est nécessaire, elles utilisent des réflecteurs, qui sont peu efficaces. De plus, elles génèrent une quantité importante de chaleur dissipée.

L'échange de puissance :

l L'ancienne méthode : Une ampoule aux halogénures métalliques de 400 W. (Remarque : avec la consommation du ballast, elle consomme en réalité environ 455 W ).

La solution LED : Un luminaire LED de 150 W peut souvent remplacer une ampoule de 400 W tout en fournissant une lumière plus efficace au sol.

Cela représente une réduction immédiate de 65 % de la consommation d'énergie. Pour un entrepôt fonctionnant 24 h/24 et 7 j/7, ce simple changement peut amortir l'installation en moins de 18 mois.

Voilà le fléau caché du budget des lampes à halogénures métalliques.

Une LED permet non seulement d'économiser de l'énergie, mais aussi du temps . Les ampoules aux halogénures métalliques ont généralement une durée de vie de 15 000 heures, mais leur durée de vie utile est bien plus courte car elles perdent rapidement en intensité. Il faut parfois les changer tous les deux ou trois ans.

Considérons maintenant le coût réel de ce remplacement :

1. Le matériel : Le coût de la nouvelle ampoule et du ballast.

2. L'équipement : Coûts de location d'une nacelle élévatrice à ciseaux ou d'une nacelle à flèche pour atteindre des plafonds de 40 pieds.

3. La main-d'œuvre : Payer deux techniciens pour une demi-journée.

4. L'arrêt : Arrêt des chaînes de production ou fermeture de sections d'une installation sportive pour des raisons de sécurité.

Avec une LED haute qualité d'une durée de vie de 50 000 à 100 000 heures, vous l'installez une fois et vous n'y pensez plus pendant une décennie. L'objectif : zéro maintenance.

En 2026 , les gouvernements et les entreprises de services publics font plus d'efforts que jamais pour atteindre l'indépendance énergétique.

De nombreux fournisseurs d'énergie proposent des remises importantes pour le remplacement des éclairages HID énergivores par des produits LED certifiés DLC (DesignLights Consortium). Dans certaines régions, ces remises peuvent couvrir jusqu'à 50 % du coût initial du projet .

Conseil de pro : Les luminaires à halogénures métalliques ne sont jamais admissibles à ces rabais. Seul le passage aux DEL permet de bénéficier de ces rabais.

Performance et qualité de la lumière

Faire des économies, c'est bien, mais pas au détriment de la qualité de l'éclairage. Heureusement, les LED améliorent considérablement l'environnement visuel, à condition de choisir le bon spectre.

Nous devons parler du L70 .

L70 est la norme industrielle pour mesurer la durée de vie. Elle désigne le moment où une source lumineuse ne conserve plus que 70 % de sa luminosité initiale .

Lampes aux halogénures métalliques : Elles subissent une « dépréciation ». Une lampe de 20 000 lumens peut n’en produire que 12 000 après seulement 12 mois. L’éclairage de votre usine baisse progressivement, réduisant lentement la productivité sans que vous vous en aperceviez.

LED : Les LED de bonne qualité se dégradent très lentement. Elles conservent leur luminosité pendant des années .

Différence Ceramiclite : Bien que les LED standard soient performantes, notre technologie Ceramic FTC est conçue pour aller encore plus loin, en maintenant une luminosité quasi identique à celle d’origine lorsque les LED à lentille en plastique commencent déjà à jaunir et à faiblir.

Pour en savoir plus : Vous souhaitez connaître la durée de vie des LED ? Consultez ce guide complet sur la durée de vie des lampes LED..

Avez-vous déjà remarqué que la lumière aux halogénures métalliques paraît un peu « orangée » ou « terne » comparée à l'éclairage moderne ?

Il s'agit d'un problème d'indice de rendu des couleurs (IRC) .

l Halogénure métallique IRC : ~60-65

LED industrielle IRC : >70 ou >80

Un IRC élevé signifie que les couleurs sont fidèles à la réalité. En milieu industriel, cela aide les opérateurs à lire correctement les étiquettes, à repérer les défauts sur la chaîne de montage et à identifier les câbles à code couleur.

De plus, la lumière LED est perçue par l'œil humain comme « plus brillante » (lumens scotopiques) même à une puissance inférieure, améliorant ainsi la sécurité et la vigilance générales dans l'établissement.

Les lampes aux halogénures métalliques émettent une quantité importante de rayonnements UV (ultraviolets) et IR (infrarouges).

l IR = Chaleur . Cela ajoute une charge à votre système CVC.

UV = Dommages . La lumière UV provoque la décoloration des emballages, la dégradation des matériaux et attire des essaims d'insectes vers les installations extérieures.

Les LED ne produisent pratiquement aucun rayonnement UV ou IR. Pour les usines agroalimentaires, les entrepôts textiles ou les espaces de vente au détail , c'est essentiel pour préserver l'intégrité des stocks.

Contrôle et fonctionnalité

Dans la gestion industrielle moderne, le contrôle est primordial. La technologie aux halogénures métalliques appartient à une époque où l'éclairage était simplement « allumé » ou « éteint ». La technologie LED propulse votre installation dans le XXIe siècle.

Si vous gérez un stade ou une grande usine, vous connaissez la panique que provoque une coupure de courant, même brève.

Avec les lampes à halogénures métalliques, une brève coupure de courant de 5 secondes entraîne une obscurité de 15 à 20 minutes. C'est ce qu'on appelle le temps de réamorçage . Le tube à arc doit refroidir complètement avant de pouvoir être rallumé. Dans un entrepôt, cela représente 20 minutes d'immobilisation pour les employés. Dans un stade, c'est une catastrophe retransmise en direct à la télévision.

Les LED s'allument instantanément . Pas de temps de préchauffage, de refroidissement ni de réallumage. Il suffit d'actionner l'interrupteur pour obtenir une luminosité maximale immédiatement. C'est un atout majeur en matière de sécurité, notamment en cas d'urgence.

Les lampes aux halogénures métalliques ne peuvent généralement pas être atténuées (ou nécessitent des ballasts très coûteux et peu fiables pour ce faire). Elles fonctionnent à pleine puissance en permanence, même lorsqu'il n'y a personne dans l'allée.

Les LED sont par nature numériques. Elles s'associent parfaitement avec :

l Capteurs de mouvement : Atténuation automatique de l'éclairage dans les allées vides des entrepôts.

l Récupération de la lumière naturelle : Réduction de la luminosité lorsque la lumière du soleil pénètre par les puits de lumière.

l Systèmes IoT : Permettent aux gestionnaires d'installations de planifier et de surveiller l'utilisation à partir d'une tablette.

Cette fonctionnalité « intelligente » peut permettre de réaliser des économies d'énergie supplémentaires de 20 à 30 %, en plus de la réduction de la consommation en watts.

Les lampes aux halogénures métalliques sont essentiellement des appareils de chauffage qui produisent également de la lumière. Elles fonctionnent à des températures internes supérieures à 2000 °F (environ 1093 °C).

Un bâtiment équipé de centaines de luminaires à halogénures métalliques de 1 000 W génère une importante chaleur. Votre système de chauffage, ventilation et climatisation (CVC) est alors contraint de fonctionner en surrégime pour refroidir l'air chauffé par ces lampes. Le passage aux LED, qui dégagent beaucoup moins de chaleur, permet souvent de réaliser d'importantes économies d'énergie sur le système CVC pendant l'été.

Partie 4 : La vérité, toute la vérité (Y a-t-il des inconvénients ?)

En tant que votre consultant, je me dois d'être honnête avec vous. Bien que la technologie LED soit supérieure, elle n'est pas invincible .

De nombreux propriétaires d'usines ont été arnaqués (au sens propre comme au figuré) en optant pour des ampoules LED bon marché, qui tombent en panne en moins de deux ans. Pourquoi cela se produit-il ?

Les LED présentent-elles des inconvénients ?

Ce n'est généralement pas la puce elle-même qui pose problème, mais son emballage.

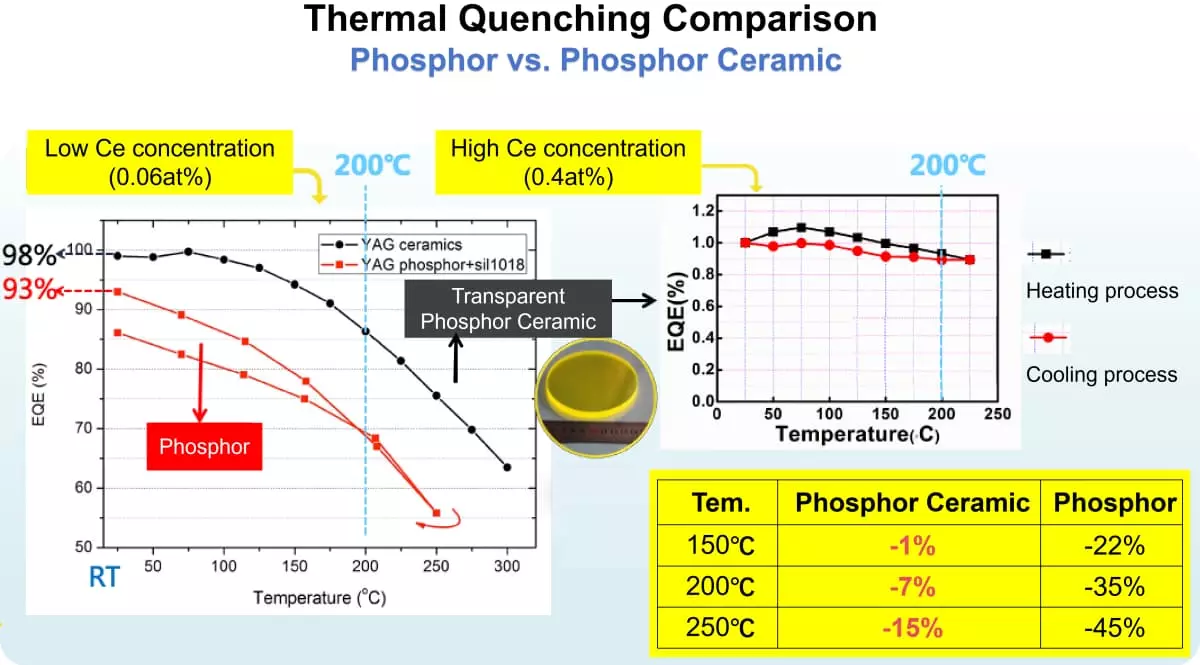

La plupart des LED standard du marché utilisent un mélange de poudre de phosphore et de colle silicone pour recouvrir la puce. Si cette solution convient parfaitement à un usage bureautique, elle présente des défauts rédhibitoires en production industrielle :

1. L’effet « éponge » (sulfuration) : Le silicone possède une structure moléculaire poreuse. Si votre installation contient du soufre, des vapeurs acides ou des brouillards d’huile lourds (fréquents dans les usines de fabrication, les usines de caoutchouc et les élevages), ces gaz pénètrent dans le silicone.

2. Noircissement : Une fois à l’intérieur, ces substances chimiques réagissent avec la couche réfléchissante argentée de la LED. Cela provoque une sulfuration (noircissement). L’argent noircit et absorbe la lumière au lieu de la réfléchir. Résultat ? Une perte de luminosité importante et une panne à terme.

3. Piégeage de la chaleur : Le silicone est un mauvais conducteur thermique. Il agit comme une couverture, emprisonnant la chaleur directement contre la puce. Lorsque la température augmente, le phosphore se dégrade, ce qui entraîne des changements de couleur et une défaillance.

Si votre environnement comprend :

l Hautes températures : (Fonderies, Aciéries).

l Exposition chimique : (Élevages de volailles avec de l'ammoniac, usines de caoutchouc avec du soufre).

l Vibrations et poussière : (Usinage lourd).

Dans ces conditions, une LED standard « silicone + phosphore » est une bombe à retardement. La nature poreuse de son boîtier garantit que les contaminants finiront par détruire la source lumineuse.

Le tournant : Alors, si les diodes électroluminescentes à halogénures métalliques sont inefficaces, mais que les LED standard encapsulées dans du silicone sont chimiquement vulnérables, quelle est la solution ?

Partie 5 : La solution supérieure : Pourquoi Ceramiclite ?

Nous avons établi que les diodes électroluminescentes métalliques sont obsolètes. Mais nous avons également révélé le secret honteux de l'industrie des LED : les LED standard encapsulées dans du silicone ne résistent pas aux environnements chimiques et thermiques extrêmes .

C’est pourquoi Ceramiclite a développé la technologie FTC (Fluorescent Transparent Ceramic).Nous n'avons pas seulement amélioré la lumière ; nous avons changé la science des matériaux qui la sous-tend.

Au-delà des LED standard : la révolution céramique (FTC)

Chez CeramicliteNous n'avons pas simplement peaufiné l'ampoule LED ; nous avons réinventé la gestion de la chaleur grâce à la technologie FTC (Fluorescent Transparent Ceramic) .

Pourquoi la FTC résout le problème :

La technologie FTC remplace le mélange traditionnel de « poudre de phosphore et de silicone » par un matériau céramique transparent fluorescent solide . Ce changement résout fondamentalement les problèmes de défaillance des LED standard.

1. Immunité à la sulfuration (effet « bouclier »)

Contrairement au silicone poreux, notre matériau FTC est une structure céramique solide et dense. Il est physiquement imperméable au soufre, à l’ammoniac, aux acides et aux alcalis.

Résultat : Les gaz corrosifs ne peuvent pas pénétrer la couche d’argent. Même après un test rigoureux de 168 heures contre la sulfuration, les puces Ceramiclite ne présentent aucun noircissement . Que vous exploitiez un élevage de volailles (ammoniac) ou une usine de pneumatiques (soufre), la lumière reste éclatante.

2. Conductivité thermique inégalée (10 W/m·K) La chaleur est l'ennemie de la lumière. Le silicone est un isolant thermique, tandis que la céramique est un conducteur thermique.

Données : Le FTC a une conductivité thermique allant jusqu'à 10 W/m·K .

Avantage : Ce matériau dissipe la chaleur de la jonction 50 fois plus rapidement que les emballages en silicone traditionnels. Nos lampes peuvent ainsi fonctionner à haute puissance (remplaçant les lampes à halogénures métalliques de plus de 1 000 W) tout en maintenant une température de surface basse (89 °C en moyenne).

3. Dégradation lumineuse nulle (<5 % sur 100 000 heures)

Parce que nous avons éliminé le silicone qui retient la chaleur et la poudre de phosphore qui se dégrade, notre stabilité est inégalée.

LED standard : Perd souvent 30 % de sa luminosité en 50 000 heures.

Ceramiclite FTC : Testé et approuvé pour une atténuation lumineuse inférieure à 5 % après 100 000 heures.

Cas d'utilisation :

Pour les gestionnaires d'installations lassés de remplacer les LED « industrielles » qui faiblissaient ou tombaient en panne à cause de la corrosion chimique ou de la chaleur, Ceramiclite offre la première véritable solution « Installer et oublier ».

Partie 6 : De la théorie à la pratique

Prêt à franchir le pas ? Voyons comment procéder correctement.

Comment convertir une lampe à halogénures métalliques en LED

Vous avez généralement deux options : la rénovation (conservation de l’ancien boîtier) ou le remplacement (nouveaux luminaires).

Ampoules LED de type « maïs » (rénovation) : Visser une ampoule LED de type « maïs » dans une douille à halogénures métalliques. Conclusion : Économique, mais surchauffe fréquente car l’ancien luminaire retient la chaleur. Déconseillé pour une utilisation industrielle prolongée.

Nouveaux luminaires (remplacement) : Démontage de l’ancien caisson lumineux encombrant et installation d’un luminaire industriel LED dédié. Verdict : Le choix des professionnels. Meilleure dissipation thermique, meilleure optique et durée de vie prolongée.

Si vous décidez de procéder à une conversion, vous ne pouvez pas simplement visser une ampoule LED dans un luminaire à halogénures métalliques. Vous devez effectuer un shunt de ballast .

Le ballast est le dispositif qui régule la tension de l'arc à halogénures métalliques. Les LED possèdent leur propre circuit de commande interne. Si vous utilisez une LED avec un vieux ballast :

1. Vous gaspillez de l'énergie (le ballast consomme de l'énergie).

2. Vous risquez de griller le pilote de la LED.

3. Le ballast est un point faible : s'il tombe en panne, votre nouvelle LED s'éteint.

Faites toujours couper le ballast du circuit par un électricien certifié.

Utilisez cette règle empirique lors de la planification de votre mise à niveau afin de garantir le maintien des mêmes niveaux de luminosité :

Lampe à halogénures métalliques Ø 400 W → Remplacer par une LED de 100 W à 150 W (Objectif : 15 000 à 20 000 lumens)

Lampe à halogénures métalliques Ø 1000 W → Remplacer par une LED de 300 W à 400 W (Objectif : 40 000 à 50 000 lumens)

Phare sport Ø 1500 W → Remplacer par un modèle LED 500 W - 600 W (Objectif : plus de 70 000 lumens)

Conclusion

Le débat est clos. La question n'est plus de savoir « si » il s'agira des lampes à halogénures métalliques ou des LED, mais « quand ».

Utiliser systématiquement des lampes à halogénures métalliques représente un gaspillage d'argent. Cependant, investir précipitamment dans des LED inadaptées (LED silicone standard) peut s'avérer tout aussi coûteux en cas de défaillance due à la sulfuration ou à la chaleur.

Prêt à arrêter de changer les ampoules ?

Ne vous fiez pas uniquement au prix d'achat ; tenez compte de la durée de vie et de la fiabilité . Un luminaire Ceramiclite allie la robustesse de la céramique à l'efficacité des LED.

Contactez Ceramiclite dès aujourd'hui pour une simulation d'éclairage gratuite. Nous vous montrerons précisément les économies que vous réaliserez au cours des 10 prochaines années.

FAQ (Foire aux questions)

Q : Quel est l'équivalent LED d'une lampe aux halogénures métalliques de 400 W ?

R : En général, un luminaire LED de 150 W est équivalent. Cependant, pour une luminosité équivalente, privilégiez un flux lumineux de 15 000 à 20 000 lumens.

Q : Pourquoi mes ampoules LED grillent-elles si vite ?

A : La principale cause est une défaillance du boîtier due à la chaleur ou à la corrosion chimique. Les LED standard utilisent du silicone, qui emprisonne la chaleur et permet au soufre de noircir la couche d'argent. Les LED à base de céramique (comme les FTC) résolvent ce problème.

Q : Les LED sont-elles meilleures que les HPS pour 2026 ?

R : Oui. Les lampes à sodium haute pression (HPS) produisent une lumière orange de mauvaise qualité. Les LED offrent un rendu des couleurs (IRC) supérieur, un allumage instantané et une meilleure efficacité énergétique.

Q : Puis-je installer une ampoule LED dans un luminaire à halogénures métalliques ?

R : Oui, mais vous devez effectuer un shunt de ballast. Laisser l'ancien ballast connecté entraînera un gaspillage d'énergie et endommagera la LED.

_thumb.jpg)