Cattle Shed Lighting: Best LED Lights for Cattle Sheds

Table of Contents

Current State of Lighting in Cattle Sheds

Analysis of Lighting Environment Requirements for Breeding

Intelligent Lighting System Design for Cattle Sheds

Cattle Shed Lighting Control Parameter Configuration

Best LED Lights for Cattle Sheds

Lighting in cattle sheds plays a crucial role in aquaculture, impacting the lactation performance and overall health of dairy cows. A well-designed lighting environment can enhance both milk production and quality, while inadequate lighting can negatively affect dairy cows' productivity and harm their health and eyesight.

This study developed an intelligent lighting system for cattle sheds, tailored to the growth, production, and health requirements of dairy cows. The system is capable of real-time monitoring, displaying, and adjusting lighting parameters based on the conditions within the cattle shed. It can modify the duration and intensity of light according to changes in the environment, ensuring optimal lighting for the growth, productivity, and health of the cows.

Additionally, to align the lighting cycle, intensity, and comfort with the actual needs of dairy cows, optimal control parameters for lighting duration and intensity were established through testing and data analysis, demonstrating that the intelligent lighting system positively influences milk production.

Current State of Lighting in Cattle Sheds

1. Poor Lighting Quality in Farming

Cattle sheds typically feature an enclosed design that relies on natural light during the day and artificial lighting at night. However, natural light varies with seasons and weather, making it unreliable for dairy farming.

Since dairy cows are ruminants that often eat and ruminate at night, they require adequate lighting during these hours. Unfortunately, most nighttime lighting in dairy farms is designed primarily for the convenience of staff, neglecting the nighttime activity needs of the cows and the effects of light on their physiological hormones.

Currently, the combination of natural and artificial lighting in large-scale dairy farms in Yunnan Province lacks scientific rigor, leading to a subpar lighting environment that fails to meet the technical standards for large-scale dairy farming.

2. Lighting Management in Cattle Sheds is Outdated

The lighting systems in cattle sheds primarily rely on traditional power distribution designs, which are manually controlled. There are no sensors for light intensity or color temperature installed in these facilities. As a result, the operation of the lights depends solely on the staff's experience or visual judgment, leading to inconsistent lighting cycles that significantly affect dairy cows' feed intake, milk production, and hormonal balance.

Additionally, standard lighting fixtures are typically used, with brightness and color chosen based on the nighttime needs of the workers rather than the cows. Since these ordinary lamps have fixed light intensity and color temperature that cannot be adjusted automatically, they fail to meet the lighting requirements of dairy cows, potentially harming their vision and overall health.

The lighting design and management practices in large dairy farms lack scientific rigor, and the control over light cycles, intensity, and color temperature does not align with the actual needs of the cows, hindering the healthy development of dairy farming.

3. Poor Lamp Selection in Cattle Sheds

Many dairy farms have misconceptions about choosing lamps for cattle sheds. The selection often prioritizes human needs, overlooking the differences in photosensitivity between cows and humans. Consequently, the lamps chosen do not align with the light sensitivity requirements of dairy cows.

Research indicates that most cattle sheds are equipped with standard LED lights and blue lights, which serve the nighttime needs of farm workers but are not visible to cows. This is because cows have only two types of cones in their retinas, making them sensitive to long-wavelength red light while being insensitive to short-wavelength blue light.

In essence, cows can see orange and red light, while blue light is invisible to them, which is the opposite of human vision. Therefore, it is unscientific to select lighting based on human photosensitivity when it should be based on what is visible to cows, necessitating the use of red and orange lights that cater to their vision.

Analysis of Lighting Environment Requirements for Breeding

1. Duration of Lighting

Dairy cows are not seasonal breeders, and their lighting environment significantly influences their endocrine system, sexual maturity, feeding habits, growth, and milk production. Recent data from dairy farms indicate that milk production under natural lighting varies with the seasons, peaking in spring and dropping in late summer and early autumn, before gradually improving after October.

Research by Li Yunfu and colleagues demonstrated that extending the daily lighting duration from 9.5 hours of natural light to 15 or 18 hours over a 30-day trial resulted in higher milk production and feed intake at 15 hours compared to both 9.5 and 18 hours.

Consequently, when designing the lighting system for large dairy farms, it is essential to consider the actual lighting duration needs of dairy cows and the impact of light cycle variations to maximize the benefits of the lighting control system.

2. Light Intensity

As ruminant mammals, dairy cows require nighttime feeding. However, they are naturally timid, and inappropriate lighting—either too dim or too bright—can disrupt their rumination and feeding.

Research indicates that optimal light intensity can enhance dairy cows' nighttime appetite, leading to improved roughage intake and conversion rates. Properly managing light intensity in the cattle shed can boost nighttime feed intake, potentially increasing overall milk production by 5% to 8%.

Therefore, the regulation of nighttime light intensity in large dairy farms should align with dairy cows' photosensitivity to meet their lighting needs effectively.

3. Color Temperature of Light

When selecting the color temperature for the cattle shed lighting, it is important to consider the visual sensitivity of dairy cows to ensure they can see well at night.

3. Intelligent Lighting System Design for Cattle Sheds

1. General Overview

The intelligent lighting system for cattle sheds operates by continuously monitoring the light intensity in each cattle shed using light sensors. The detected light intensity is converted into a 4-20 mA analog signal via a photoelectric conversion module, which is then sent to the analog card channel of the S7-1500 PLC.

After processing the data, the PLC's CPU issues control commands for lighting duration and intensity to each lamp. To enhance the flexibility and ease of lighting management, a touch screen is installed in the control cabinet of each cattle shed for local operation, while a monitoring host in the monitoring room allows for remote oversight.

Additionally, each cattle shed can transmit data to the cloud through a secure wireless gateway, enabling real-time monitoring via a mobile app. The primary goal is to develop a smart dairy farming system characterized by digitalization, automation, and intelligence, which is essential for the high-quality advancement of dairy farming.

2. Hardware Architecture

The system features a three-tier architecture comprising a device layer, control layer, and application layer. The device layer at the bottom includes light sensors and specialized lights for cows. The middle control layer consists of the S7-1500 PLC, touch screen, switches, safety isolation devices, and a wireless gateway. The top application layer includes the monitoring host and mobile smart terminal.

3. Equipment Selection

3.1 Choosing Specialized Lamps Based on Cow Eye Photosensitivity

Currently, most dairy farms in Yunnan Province utilize standard LED lights operating at AC 220 V. However, these ordinary LED lights have a color temperature exceeding 5.000 K, which does not align with the photosensitivity needs of dairy cows.

Furthermore, these lamps tend to flicker and provide uneven lighting, adversely affecting the nighttime behavior of dairy cows. Given that dairy cows are naturally timid, they can experience stress when startled, leading to a significant decrease in milk production.

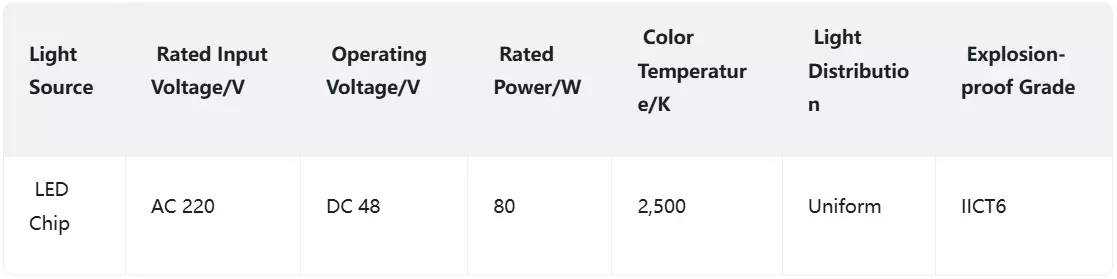

Additionally, the light intensity and color temperature of standard LED lights are not adjustable, failing to meet the lighting design requirements for large-scale dairy operations. To address the specific lighting needs of dairy cows, this study has customized a special lamp for lactating cattle sheds, featuring an LED light source with adjustable intensity and standard color, sourced from Zhongshan Yuqiu Lighting Co., Ltd., model MRGZ01. with specifications detailed in Table 1.

Tab.1 Parameters of Special Lamps for Lactation Cattle Shed

3.2 Light Sensor Selection

Given the extensive area of the cattle shed, this study chose the RS-GZ-N01-2 light sensor from Shandong Renke Measurement and Control Technology Co., Ltd. to accurately measure the ground light intensity.

This sensor has a measurement accuracy of ±7%. It converts the measured light intensity into a 4-20 mA standard signal, which is then transmitted to the PLC's analog channel via a communication cable. The sensor is installed in the feeding aisle at a height of 60 to 80 cm from the ground, which aligns with the height of the cows' eyes during feeding.

3.3 PLC Controller Selection

PLC control technology has proven effective in agriculture, fulfilling the reliability and real-time requirements for lighting control systems. After analysis, the Siemens S7-1500 PLC controller was chosen for the intelligent lighting system. It includes an Ethernet communication module, an analog input module, an analog output module, a switch input module, and a switch output module.

The analog input module receives the 4-20 mA signal from the light sensor, while the analog output module sends brightness adjustment commands to the cattle shed lights. The switch output module controls the lights' on/off status, and the switch input module gathers operational status information from both the cattle shed lights and the light sensor.

Additionally, the Ethernet communication module facilitates communication between the local PLC, touch screen, and background switch, enabling both local and remote control of the cattle shed lighting.

4. Control Circuit Design

4.1 Intelligent Lighting System Control Circuit

To achieve consistent lighting in the feeding aisle of the cattle shed, 16 specialized lights for cow eyes are installed in each cattle shed, all connected in parallel and controlled by a single AC contactor. To maintain voltage quality when all lights are on, the first and third cattle sheds use L1-N wiring, the second cattle shed uses L2-N wiring, and the fourth cattle shed uses L3-N wiring.

4.2 Allocation of Control Signals for Intelligent Lighting System

To enable the PLC control unit to gather real-time lighting data from each cattle shed and oversee the lights' operational status, the intensity of the specialized lights for cows' eyes can be controlled intelligently. This includes switch input signals for light activation, deactivation, light failure, and light sensor failure, along with an analog input signal for illumination.

Additionally, there are switch output commands for turning the lights on and off, as well as analog output commands for adjusting illumination. The I/O configuration for the lighting system is presented in Table 2.

Tab.2 Light system I / O distribution

4.3 External Wiring Design for PLC

To facilitate communication between the PLC control unit, the light sensor, and the specialized lamp for cow eyes, the external wiring design for the PLC control unit in each cattle shed.

5. Cattle Shed Lighting System Control Mode

The lighting system for the cattle shed operates in two modes: manual and automatic. Staff can manually adjust the lighting using a touch screen, a background monitoring host, or a mobile app, allowing them to monitor the lighting status and environmental conditions of each cattle shed in real time through the user interface. In automatic mode, the PLC system manages the lighting by automatically turning it on and off and adjusting the brightness based on pre-defined cycles, light intensity, and other factors.

The aim of fixed light cycle control is to enhance the hormonal response in cows by alternating between periods of light and darkness, thereby optimizing their production performance. Based on the feeding and resting habits of dairy cows, the light cycle is categorized into a light phase lasting 15 to 18 hours and a dark phase lasting 6 to 9 hours. When the automatic fixed light cycle mode is activated, the system will turn on the lights in the cattle shed daily from 07:00 to 24:00 and switch them off at other times to ensure adequate lighting for the cows.

The goal of fixed light illumination control is to provide dairy cows with a comfortable light intensity that boosts their appetite, leading to increased roughage intake and milk production during the night. When this control mode is implemented, the system automatically monitors the current light intensity using a sensor, processes this data against pre-set control parameters in the PLC program, and sends adjustment commands to the specialized cow eye lamps to maintain the desired light intensity in the cattle shed.

6. Design of Human-Computer Interaction Interfaces

酪農の情報化を促進し、環境モニタリングを容易にし、酪農場の遠隔管理を可能にし、牛舎の照明管理ニーズに効果的に対応するために、手動制御モードと自動制御モードの両方が実装されています。手動モードでは、担当者が各牛舎の照明を手動でオン・オフし、必要な照明の明るさ調整に基づいて制御パラメータを入力します。

自動制御モードでは、固定光サイクル制御または固定光強度制御のいずれかを選択できます。

牛舎照明制御パラメータ設定

1. 構成方法の説明

牛舎照明システムと産業用照明制御システムの主な違いは、制御パラメータの設定と照明効果の評価にあります。産業用照明システムでは、パラメータ設定のプロセスが簡潔で、制御応答が速く、照明の快適性をより簡単に評価できます。

一方、牛舎照明システムのパラメータ設定と最適化サイクルは長く複雑であるため、工業的な手法には適していません。牛舎照明パラメータの調整は、牛の視点から行う必要があります。照明パラメータの変更は、牛の生産パフォーマンスと健康にゆっくりと影響を与える可能性があり、飼料摂取量や乳量に顕著な影響が現れるまでに時間がかかります。

したがって、本研究では、牛乳の生産量を主要な評価指標として使用し、制御テストとデータ分析を使用して牛舎のインテリジェント照明システムの照明期間と強度を微調整し、最終的に制御システムに最も効果的な照明期間と強度のパラメータを選択することを提案しています。

2. インテリジェント照明システム制御パラメータの設定

雲南省の酪農場から、平均乳量(24.6±2.8)kg/週、平均産卵回数(2.2±0.9)回、平均体長(143±69)cmの健康な泌乳牛50頭をサンプルとして選びました。

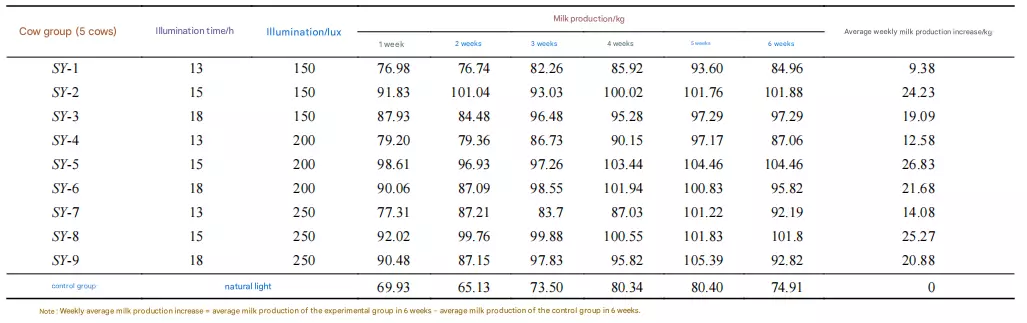

対照群として5頭の牛を無作為に選び、自然光が入る伝統的な牛舎に飼育しました。一方、45頭の牛を9つのグループに分け、光照射時間と光強度の変化が乳量に及ぼす影響を調べました。各実験因子は、光照射時間13時間、15時間、18時間、光強度150ルクス、200ルクス、250ルクスの3つのレベルで試験されました。

実験全体を通して、すべての牛に同じ配合の濃厚飼料、粗飼料、その他の飼料成分を与えました。試験パラメータと結果は表3に示されています。

表3 乳牛舎照明試験データ

3. テスト結果とパラメータの決定

乳牛の生産パフォーマンスは、遺伝、環境、生理など、いくつかの重要な要因の影響を受けます。乳牛の生産パフォーマンスを向上させるには、これらの影響要因を徹底的に理解することが不可欠です。

表3に示すように、乳生産量の週平均増加率はグループ間で異なり、牛舎内の照明時間と照度が乳生産量に異なる影響を与えることを示唆しています。SY-5グループは乳生産量の週平均増加率が最も高く、乳牛の生産パフォーマンスにとって照明時間15時間と照度200ルクスが最も有益であるという予備的な結論に至りました。

照明の持続時間と強度が乳生産に与える影響をさらに調査するために、表 3 を再編成し、計算して分析し、その結果を表 4 に示します。

表4 テスト結果の比較分析

表 4 は、照明時間が 15 時間であった 3 つのテストでの乳生産量の最も高い平均増加が 25.44 kg であったことを示しており、この照明時間は 13 時間や 18 時間と比較して乳牛の乳生産量により大きな影響を与えたことを示しています。

さらに、200ルクスの光強度による乳量増加のピーク平均値は20.36kgであり、この光強度は150ルクスや250ルクスよりも効果的であることが示されました。照明時間による乳量増加の変動(13.43kg)は、光強度による変動(2.79kg)よりもかなり大きく、照明時間が乳牛の乳量に影響を与える主な要因であることを浮き彫りにしています。この結果は、15時間の照明と200ルクスの光強度の組み合わせが酪農場にとって最適であることを示唆しています。

本研究では、実験群の乳牛における週平均の乳量増加を評価し、SY-5群の15時間の照明時間と200ルクスの照度がインテリジェント照明制御システムの理想的なパラメータであることを確認しました。制御された試験を通じて照明時間と照度を調整するというアプローチは、実験の後期段階における酪農場における乳量全体の向上に効果的であることが証明されており、他の飼育環境パラメータの調整にも応用できます。

従来の酪農場では、通常、人間の光感受性と作業要件に基づいて牛舎の照明システムを設計しており、牛特有の光感受性が無視され、照明の設計と制御において牛の快適性が考慮されていないことがよくあります。

本研究では、雲南省の大規模酪農場における照明管理・制御のニーズを調査し、システムアーキテクチャ、ハードウェアコンポーネント、制御方法、ヒューマンコンピュータインタラクションインターフェース、そしてシーメンスS7-1500 PLC制御フレームワークに基づく制御パラメータ設定を含むインテリジェント照明システムソリューションを提案する。これは、雲南省の大規模酪農場における飼育環境のインテリジェント管理のための技術的参考資料となり、他の大規模酪農事業における照明条件の設計改善を促すことを目指している。

5. 牛舎に最適なLEDライト

_thumb.jpg)