家禽照明如何影响生产和生长?

目录

为什么家禽照明灯对现代农场至关重要?

人们通常误以为养鸡场安装照明是为了方便工作人员操作。但实际上,养鸡场的照明会直接影响家禽的生理机能。

鸡和其他家禽感知的光谱范围比人类更广,包括紫外线,它们的生长和繁殖与光信号密切相关。光照的持续时间、强度和光谱通过下丘脑-垂体-性腺轴影响激素释放,从而调节产蛋、生长和生育能力。

在封闭式或大型养鸡场中,自然光照要么不稳定,要么完全缺失。缺乏适当的人工照明会导致蛋鸡产蛋率下降、肉鸡生长不均,种鸡繁殖力降低。因此,有效的照明并非可有可无,而是确保更高产、鸡群行为稳定和饲料转化率的关键管理手段。

家禽照明关键参数详解

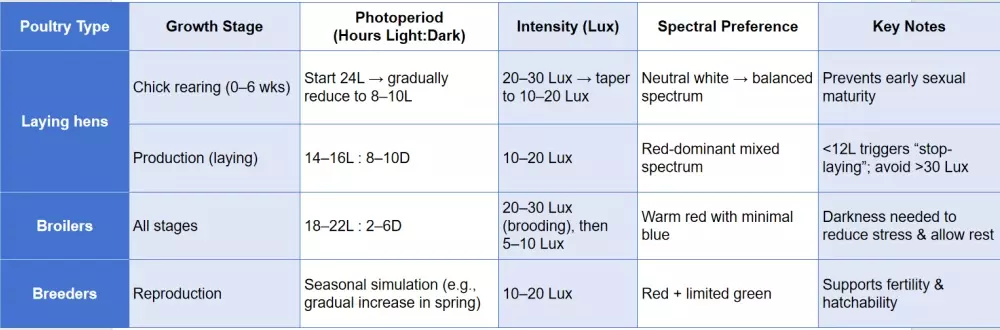

鸡舍的LED照明 不仅仅是开关灯那么简单。光周期、强度、光谱和节奏这四个技术因素共同作用,影响着家禽的生长、行为和产蛋量。

下面我们将用简单的术语来分解它们,重点介绍蛋鸡、肉鸡和种鸡的不同需求。

1. 光照周期——“灯应该开多久?”

每日光照时长直接影响鸟类的生长和繁殖周期。养殖户必须根据鸟类的种类和生长阶段来调整光照时间:

(1)蛋鸡:

产蛋期:需要14-16小时的持续光照(例如,16小时光照:8小时黑暗)。如果光照时间低于12小时(例如在冬季),母鸡会收到“停止产蛋”的信号。

雏鸡饲养(0-6周):光照时间逐渐从24小时减少到8-10小时。这可以防止母鸡过早成熟。

(2)肉鸡:

它们一生需要18-22小时的光照。日照时间长会延长进食时间,从而促进体重增加。然而,至少2-4小时的黑暗对于休息和缓解压力至关重要。

(3)育种者:

光照时间应模拟自然季节变化。逐渐延长日照时间可以提高受孕率和产卵率。

常见错误:认为“时间越长越好”。例如,给蛋鸡20小时以上的光照实际上会给母鸡带来压力,降低受孕率,并减少产蛋量。

2. 光照强度——“应该有多亮?”

光照强度以勒克斯(Lux)为单位(1勒克斯≈阴天室内房间的亮度)。不同生长阶段和家禽品种对光照强度的要求也不同:

(1)育雏(0-2 周):20-30 勒克斯。明亮的光线有助于雏鸡快速找到饲料和水,降低早期死亡率。

(2)产蛋鸡(生产阶段):光照强度10–20勒克斯。光照过强(>30勒克斯)会导致母鸡烦躁不安,并出现啄羽等有害行为。光照过弱(<5勒克斯)会降低采食量和产蛋量。

(3)肉鸡(育肥期):5-10勒克斯。较低的光照强度可使鸡只保持平静,减少运动造成的能量浪费,并促进快速增重。

实用技巧:灯光必须均匀分布在房屋内。避免出现暗角(<3勒克斯)或强光点。调整吊灯高度(离地2-3米)和灯具间距(每隔2-3米),以达到平衡。

3. 光谱成分——“哪些颜色最重要?”

近年来,家禽照明研究的重点是光谱优化,挑战了“任何白光都可以”的旧观念。

传统白炽灯偏向暖光(以红色为主),而荧光灯偏向冷光(以蓝色为主)。然而,两者的光谱范围都有限,无法精确满足家禽的需求。

相比之下,LED光谱可以定制,每个波长都发挥着不同的作用:

红光 (620–660纳米)可促进蛋鸡产蛋,并加速肉鸡增重;

蓝光 (450-495纳米)抑制肉鸡活动,但可能引起应激;

绿光 (520–560纳米)有助于增加鸡蛋重量;

UV -A(320–400 nm)支持维生素D3的合成,但需要严格控制。

实际上,建议蛋鸡舍采用以红色波长为主的混合光,而肉鸡舍则应优先采用蓝色含量较低的暖红色光。

4. 光照节奏——“持续性还是间歇性?”

照明计划可以是连续的,也可以是循环的:

(1)持续照明:

例子:

连续16小时。方法简单,但能耗高,而且会让鸟儿更容易疲劳。

(2)间歇照明:

例子:

分层:2 小时光照 / 2 小时黑暗(重复)。

肉鸡:1 小时光照/3 小时黑暗(循环)。

间歇性节律的益处:

节能30-50%。

让鸟类获得更多休息,降低压力和攻击性。

研究表明,与持续光照相比,产蛋率可以略有提高。

重要提示:作息时间必须保持稳定。频繁的改变会扰乱昼夜节律,给鸡群带来压力。

简而言之:

如果运用得当,这些参数可以将照明从一种辅助工具转变为提高家禽生产性能的强大工具。

从“传统灯具”到“智能照明”

过去几十年,家禽养殖的照明技术发生了翻天覆地的变化。每个阶段都带来了进步,但也存在局限性,这解释了为什么现在的养殖场都在向LED和智能系统转型。

白炽灯曾经是标准照明设备。它们的光谱接近自然阳光,而且前期成本低。然而,它们大部分能量都以热量的形式散失,寿命只有大约1000小时,而且不适合现代大型住宅。它们现在只适用于小型后院或临时照明场所。

与白炽灯相比,荧光灯能耗更低,亮度更高。然而,它们的光谱输出固定,含有汞,而且通常寿命只有8000小时左右。许多中型农场在能源转型时期都采用了荧光灯,但如今出于环保考虑以及光谱控制能力有限,荧光灯的价值受到了限制。

LED灯已成为主流选择。它们可降低高达70%的能耗,使用寿命超过5万小时,并可根据肉鸡、蛋鸡或种鸡的需求定制光谱设计。此外,它们不含汞,环保无害。虽然初始成本较高,但其长期性能和效率使LED灯成为集约化养鸡场最具成本效益的选择。

最新的技术是智能LED照明系统。除了高效节能之外,它们还能通过应用程序或中央管理软件进行远程控制,自动调节光照周期,并可与温湿度传感器集成。这些系统能够动态调整照明方案,确保作物在最大限度减少人工干预的情况下实现最佳生长和繁殖。虽然它们的初始成本较高,且需要专业人员安装,但对于追求精准管理的现代化农场而言,智能照明带来的益处是无可比拟的。

针对不同家禽类型的定制照明方案

照明策略绝不应该“一刀切”。不同种类的家禽对光照的反应各不相同,因此养殖户必须针对蛋鸡、肉鸡和种鸡制定不同的照明方案。

(1)蛋鸡(产蛋鸡)

光周期:生产期光照 16 小时(例如 5:00–21:00),休息期光照 8 小时。

强度:全屋均匀 15 勒克斯;避免阴影角落低于 10 勒克斯。

光谱:红光与蓝光的比例为 3:1(约 660 纳米红光 + 450 纳米蓝光),并限制 UV-A 照射(每天 1-2 小时),以提高钙吸收率和贝壳强度。

节律:间歇性循环(2 小时光照 + 2 小时黑暗)有助于节省能量,同时减少压力行为。

了解更多关于鸡舍照明对鸡蛋生产的影响。

(2)肉鸡(肉用禽类)

光周期:育雏期(0-2 周)24 小时光照,然后从第 3 周开始 20 小时光照 + 4 小时黑暗(例如,6:00-2:00)。

强度:育雏期为 25 勒克斯,以促进进食和饮水;生长阶段降低至 8 勒克斯,以限制活动并提高饲料转化率。

光谱:以红色为主(660 nm 处约占 70%),蓝色含量极少(<10%),以最大程度地减少压力。

节奏:早期持续光照,然后转为间歇循环(1 小时光照 + 3 小时黑暗),以平衡生长和休息。

(3)育种者

光周期:季节性模拟——逐渐将日照时间从 12 小时延长至 16 小时,如同春季一样。

强度:15-20勒克斯,强度足以支持活动,但又不会过强,以免干扰交配。

光谱:采用宽光谱照明(红、绿、蓝),模拟自然日光,刺激繁殖行为。

节律:在活跃期持续光照,以维持稳定的交配模式。

如果应用得当,这些量身定制的照明方案可以提高所有家禽舍的生产性能、动物福利和生产效率。

5. 家禽照明常见问题及解决方案

即使制定了周密的照明计划,日常农场管理中也常常会出现照明问题。以下是最常见的照明问题及相应的解决方案。

问题 1:光照分布不均匀

原因:灯具悬挂过高、灯具间距过大或灯具功率不足。

解决方案:采用交错式悬挂方式,而非直线悬挂。选择广角LED灯(光束角≥120°)。在角落处加装辅助灯,消除暗区。

问题二:产蛋量突然下降(排除疾病因素)

可能的原因:定时器故障导致光照时间缩短,灯泡故障导致光照强度降低,或者更换灯泡后光谱发生突变。

解决方法:每周检查定时器和灯具。更换灯具时,新灯管应在完全更换前用一周时间逐步适应。除非根据植物生长阶段进行调整,否则应保持光周期、光照强度和光谱稳定。

问题3:肉鸡啄羽或同类相食现象

原因:亮度过高(>10勒克斯)、蓝光过多或黑暗时间不足。

解决方案:将光照强度降低至 5–8 勒克斯。调整光谱,增加红色光,减少蓝色光。保证每天至少 4 小时连续黑暗环境,以保证充足的休息。

问题 4:照明成本高

解决方案:升级为LED灯具,节能高达70%。采用间歇式照明模式,减少照明时间。安装智能控制器,根据日光自动调节亮度,减少晴天时人工照明的使用。

家禽养殖LED照明的智能绿色未来

The future of poultry lighting is moving beyond simple illumination. For large-scale farms, the next decade will be defined by smart integration and sustainable design.

(1) Smart upgrades

Light–climate–feed integration: Smart systems will connect lighting with temperature, humidity, and feed intake data. For example, during heat stress, the system can automatically dim lights to reduce metabolic load.

Targeted lighting: With cameras and sensors, farms may provide individualized light programs. Weak or sick birds could receive longer photoperiods to encourage feeding, while the rest of the flock follows standard cycles.

Data-driven management: Systems will log photoperiods, intensity, and production metrics like egg count or weight gain. AI analysis will then suggest or automatically apply optimized lighting schedules tailored to each flock’s performance.

(2) Green development

Energy efficiency: Research is pushing LED efficiency beyond 150 lumens per watt, cutting power costs further. Solar-assisted systems are likely to become viable for remote or off-grid farms.

Eco-friendly materials: Mercury-free, recyclable fixtures will become the industry standard, aligning with environmental regulations and farm sustainability goals.

Welfare-focused lighting: Welfare directives, especially in Europe, are driving adoption of sunrise–sunset simulation instead of abrupt on/off cycles. Such gradual transitions reduce stress and improve overall flock health.

As technology advances, poultry LED lighting will no longer be just about visibility—it will become a central tool for precision farming, sustainability, and animal welfare.

Conclusion: Poultry Lights as a High-Return Investment

For farmers, poultry lighting is not a background detail—it is a direct driver of production, welfare, and profitability. The right program can improve egg yield, shorten growth cycles, and reduce stress, while poor lighting undermines all of these.

Traditional lamps may seem affordable, but their high energy use, short lifespan, and limited control make them costly over time. By contrast, poultry LED lighting offers precise spectrum tuning, stable intensity, and smart automation that align with modern farm needs. It reduces electricity bills, lowers maintenance, and creates healthier conditions for layers, broilers, and breeders alike.

The path forward is clear: adopting poultry LED lighting is not just an upgrade—it is an investment in long-term performance, sustainability, and competitiveness. For farms aiming to maximize efficiency and prepare for future demands, switching to LED is the most practical and profitable decision today.

Related Product

FAQs

Q1: Which light is better for broilers?

答:白光(全光谱LED灯)最适合肉鸡。与红光相比,白光可使采食量、肌肉生长和体重增加提高8-10%。白光还有助于保持稳定的饲料转化率(白光下饲料转化率为1.6,而红光下为1.8)。

Q2:为什么红光照射会导致产卵量减少?

答:红光可能过早触发催产素释放,缩短卵黄沉积时间。这会导致30周后鸡蛋重量降低。可通过在筑巢区域添加绿光(5勒克斯)来改善钙代谢和蛋壳质量,从而弥补这一不足。

Q3:红光能提高蛋鸡的产蛋量吗?

答:是的,红光(660纳米)通过刺激生殖激素,在长期使用(18-60周)过程中加速性成熟并增加产卵量。然而,与白光或绿光相比,红光照射下产出的卵重量始终较小,尤其是在30周后。

就鸡蛋质量而言,绿光优于红光,能产生更厚更坚固的蛋壳。

Q4:红光如何影响鸡的行为?

答:红光波长较长(660纳米),对昼夜节律的干扰最小,因此能减轻压力。它能促进动物的被动行为(休息、梳理羽毛),并减少群体中的攻击性。

相比之下,蓝光会增加家禽的焦虑(例如,喘气、鸭群聚集),而白光则能维持行为稳定性。

_thumb.jpg)