Comment l'éclairage des élevages de volailles affecte-t-il la production et la croissance ?

Table des matières

Pourquoi l'éclairage avicole est-il essentiel dans les élevages modernes ?

Explication des principaux paramètres de l'éclairage pour volailles

Des lampes traditionnelles à l'éclairage intelligent

Plans d'éclairage adaptés aux différents types de volailles

Problèmes courants liés à l'éclairage des élevages de volailles et solutions

L'avenir intelligent et écologique de l'éclairage LED pour l'élevage de volailles

Conclusion : L'éclairage avicole est un investissement à haut rendement

Pourquoi l'éclairage avicole est-il essentiel dans les élevages modernes ?

On croit souvent, à tort, que l'éclairage des élevages de volailles sert uniquement au confort du personnel. En réalité, cet éclairage a un impact direct sur la biologie des oiseaux .

Les poulets et autres volailles perçoivent un spectre lumineux plus large que les humains, incluant les ultraviolets, et leur croissance et leur reproduction sont étroitement liées aux signaux lumineux. La durée, l'intensité et le spectre de la lumière influencent la libération d'hormones via l'axe hypothalamo-hypophyso-gonadique, qui régule la production d'œufs, la croissance et la fertilité.

Dans les élevages avicoles fermés ou de grande taille, la lumière naturelle est soit irrégulière, soit totalement absente. Sans éclairage artificiel adéquat, la ponte des poules pondeuses peut diminuer, la croissance des poulets de chair peut être inégale et la fertilité des reproducteurs peut être compromise. Un éclairage efficace est donc indispensable : c’est un outil de gestion essentiel qui garantit une production accrue, un comportement stable du troupeau et une meilleure efficacité alimentaire.

Explication des principaux paramètres de l'éclairage pour volailles

L'éclairage LED d'une grange ne se résume pas à allumer et éteindre les lampes. Quatre facteurs techniques — la photopériode, l'intensité, le spectre et le rythme — interagissent pour influencer la croissance, le comportement et la productivité des volailles.

Nous les expliquons ci-dessous en termes simples, en soulignant les différents besoins des poules pondeuses , des poulets de chair et des reproducteurs .

1. Photopériode – « Combien de temps les lumières doivent-elles rester allumées ? »

La durée d'exposition quotidienne à la lumière influe directement sur la croissance et le cycle de reproduction des oiseaux. Les éleveurs doivent adapter les programmes en fonction de l'espèce et du stade de croissance.

(1) Poules pondeuses :

Phase de ponte : Les poules ont besoin de 14 à 16 heures de lumière continue (par exemple, 16 h de lumière : 8 h d’obscurité). Si la durée d’éclairage descend en dessous de 12 heures (comme en hiver), elles reçoivent un signal d’arrêt de ponte.

Élevage des poussins (0 à 6 semaines) : La durée d’éclairage est progressivement réduite de 24 heures à 8-10 heures. Ceci permet d’éviter que les poules n’atteignent leur maturité trop tôt.

(2) Poulets de chair :

Les animaux ont besoin de 18 à 22 heures de lumière tout au long de leur vie. Les longues journées allongent la durée des repas, ce qui entraîne une prise de poids. Cependant, au moins 2 à 4 heures d'obscurité sont essentielles pour le repos et la réduction du stress.

(3) Éleveurs :

Les cycles lumineux doivent imiter les variations saisonnières naturelles. L'allongement progressif de la durée du jour améliore la fertilité et le taux de ponte.

Erreur fréquente : croire que « plus long, c’est toujours mieux ». Par exemple, exposer les poules pondeuses à plus de 20 heures de lumière les stresse, réduit leur fertilité et diminue la production d’œufs.

2. Intensité lumineuse – « Quel niveau de luminosité doit-elle atteindre ? »

L'intensité lumineuse se mesure en lux (1 lux ≈ luminosité d'une pièce intérieure couverte). Les différents stades de développement et les types de volailles requièrent des niveaux différents :

(1) Couvée (0–2 semaines) : 20–30 Lux. Une lumière vive aide les poussins à trouver rapidement de la nourriture et de l'eau, réduisant ainsi la mortalité précoce.

(2) Poules pondeuses (phase de production) : 10–20 lux. Un éclairage trop fort (> 30 lux) les rend agitées et peut provoquer des comportements nuisibles comme le picage. Un éclairage trop faible (< 5 lux) réduit leur consommation d’aliments et la production d’œufs.

(3) Poulets de chair (phase d'engraissement) : 5–10 Lux. Une luminosité plus faible permet aux oiseaux de rester plus calmes, réduit le gaspillage d'énergie lié aux mouvements et favorise une prise de poids rapide.

Conseil pratique : La lumière doit être répartie uniformément dans la pièce. Évitez les zones d'ombre (moins de 3 lux) et les points chauds. Ajustez la hauteur de suspension (2 à 3 m du sol) et l'espacement des lampes (tous les 2 à 3 m) pour un éclairage équilibré.

3. Contenu spectral – « Quelles couleurs sont les plus importantes ? »

Ces dernières années, la recherche sur l'éclairage des volailles s'est concentrée sur l'optimisation du spectre, remettant en question l'ancienne croyance selon laquelle « n'importe quelle lumière blanche fera l'affaire ».

Les lampes à incandescence traditionnelles émettent une lumière chaude (à dominante rouge), tandis que les lampes fluorescentes émettent une lumière froide (à dominante bleue). Cependant, leurs spectres d'éclairage sont limités et elles ne répondent pas précisément aux besoins des volailles.

En revanche, les spectres des LED peuvent être personnalisés, chaque longueur d'onde jouant un rôle différent :

la lumière rouge (620–660 nm) favorise la production d’œufs chez les pondeuses et accélère la prise de poids chez les poulets de chair ;

la lumière bleue (450–495 nm) supprime l’activité des poulets de chair mais peut provoquer du stress ;

la lumière verte (520–560 nm) peut contribuer à augmenter le poids des œufs ;

l UV-A (320–400 nm) favorise la synthèse de la vitamine D3 mais nécessite un contrôle rigoureux.

En pratique, une lumière mixte à dominante rouge est recommandée pour les poulaillers de poules pondeuses, tandis que les poulaillers de poulets de chair devraient privilégier une lumière rouge chaude à teneur réduite en bleu.

4. Rythme lumineux – « Continu ou intermittent ? »

Les programmes d'éclairage peuvent être continus ou divisés en cycles :

(1) Éclairage continu :

Exemple:

16 heures d'affilée. Simple, mais avec une forte consommation d'énergie et une fatigue accrue chez les oiseaux.

(2) Éclairage intermittent :

Exemple:

Couches : 2 heures de lumière / 2 heures d'obscurité (en boucle).

Poulets de chair : 1 heure de lumière / 3 heures d'obscurité (en boucle).

Avantages du rythme intermittent :

Permet d'économiser de 30 à 50 % d'énergie.

Permet aux oiseaux de mieux se reposer, réduisant ainsi le stress et l'agressivité.

Les recherches montrent que les taux de ponte peuvent être légèrement améliorés par rapport à la lumière continue.

Remarque importante : les rythmes doivent rester constants. Des changements fréquents perturbent le rythme circadien et stressent le troupeau.

En bref:

Correctement appliqués, ces paramètres transforment l'éclairage d'un simple outil utilitaire en un puissant vecteur de performance pour l'élevage de volailles.

Des lampes traditionnelles à l'éclairage intelligent

L'éclairage utilisé en élevage avicole a connu une évolution spectaculaire ces dernières décennies. Chaque étape a apporté des progrès, mais aussi des limitations qui expliquent pourquoi les exploitations se tournent aujourd'hui vers les LED et les systèmes intelligents.

Les lampes à incandescence ont longtemps été la norme. Leur spectre est proche de celui de la lumière naturelle et leur coût initial est faible. Cependant, elles gaspillent la majeure partie de leur énergie sous forme de chaleur, leur durée de vie n'est que d'environ 1 000 heures et elles ne conviennent pas aux grandes maisons modernes. Elles restent pratiques uniquement pour les petits jardins ou les installations temporaires.

Les lampes fluorescentes ont permis de réduire la consommation d'énergie par rapport aux lampes à incandescence et d'offrir une luminosité supérieure. Cependant, elles fonctionnent selon un spectre lumineux fixe, contiennent du mercure et ont une durée de vie d'environ 8 000 heures. De nombreuses exploitations agricoles de taille moyenne les ont adoptées durant la période de transition énergétique, mais les préoccupations environnementales et le contrôle limité du spectre lumineux restreignent aujourd'hui leur intérêt.

L'éclairage LED est devenu la norme. Il permet de réduire la consommation d'énergie jusqu'à 70 %, offre une durée de vie de plus de 50 000 heures et permet une conception spectrale adaptée aux poulets de chair, aux poules pondeuses ou aux reproducteurs. De plus, il est sans mercure et respectueux de l'environnement. Malgré un coût initial plus élevé, ses performances et son efficacité à long terme font des LED l'option la plus rentable pour les élevages de volailles intensifs.

La dernière innovation réside dans les systèmes LED intelligents . Outre leur efficacité, ils permettent le contrôle à distance via des applications ou un logiciel de gestion centralisé, la programmation automatique des photopériodes et l'intégration avec des capteurs climatiques pour la température et l'humidité. Ces systèmes ajustent dynamiquement les programmes d'éclairage, garantissant une croissance et une reproduction optimales avec une intervention manuelle minimale. Leur coût initial et la nécessité d'une installation professionnelle sont plus élevés, mais pour les exploitations agricoles modernes visant une gestion de précision, l'éclairage intelligent offre des avantages inégalés.

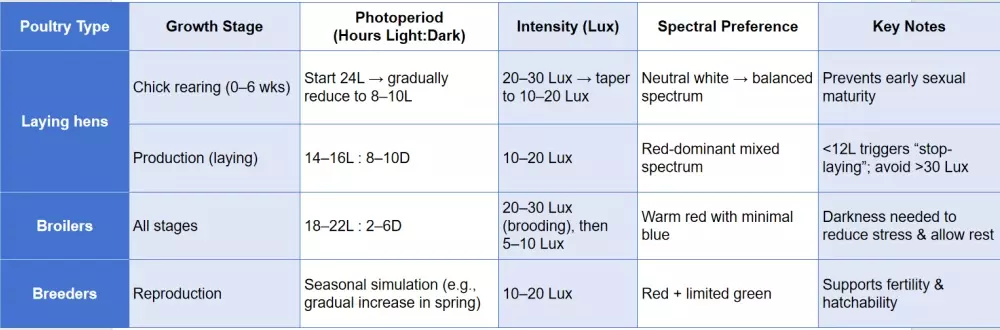

Plans d'éclairage sur mesure pour différents types de volailles

Les stratégies d'éclairage ne doivent jamais être « standardisées ». Les différentes catégories de volailles réagissent différemment à la lumière ; les éleveurs doivent donc adapter leurs programmes aux pondeuses, aux poulets de chair et aux reproducteurs.

(1) Poules pondeuses

Photopériode : 16 heures de lumière pendant la production (par exemple, 5h00-21h00) et 8 heures en phase de repos.

Intensité : 15 Lux uniformément dans toute la maison ; éviter les coins ombragés en dessous de 10 Lux.

Spectre : Rapport rouge/bleu de 3:1 (environ 660 nm rouge + 450 nm bleu), avec une exposition limitée aux UV-A (1 à 2 heures par jour) pour améliorer l'absorption du calcium et la résistance de la coquille.

Rythme : Les cycles intermittents (2 h de lumière + 2 h d'obscurité) aident à économiser l'énergie tout en réduisant les comportements liés au stress.

Apprenez-en davantage sur l'éclairage des poulaillers pour la production d'œufs .

(2) Poulets de chair (oiseaux de viande)

Photoperiod: 24 h light in the brooding phase (0–2 weeks), then 20 h light + 4 h dark from week 3 onward (e.g., 6:00–2:00).

Intensity: 25 Lux during brooding to encourage feeding and drinking; reduce to 8 Lux in the grow-out phase to limit activity and improve feed conversion.

Spectrum: Dominantly red (≈70% at 660 nm) with minimal blue (<10%) to minimize stress.

Rhythm: Continuous light early, then switch to intermittent cycles (1 h light + 3 h dark) to balance growth and rest.

(3) Breeders

Photoperiod: Seasonal simulation—gradually extend daylight hours from 12 to 16 as in spring.

Intensity: 15–20 Lux, strong enough to support activity but not excessive, which could disrupt mating.

Spectrum: Broad-spectrum lighting (red, green, blue) to mimic natural daylight and stimulate breeding behaviors.

Rhythm: Continuous light during the active phase to maintain consistent mating patterns.

When applied correctly, these tailored lighting programs improve performance, welfare, and efficiency across all poultry houses.

5. Common Problems in Poultry Lights and Solutions

Even with well-planned programs, lighting issues often appear in daily farm management. Below are the most frequent problems and actionable poultry lighting solutions.

Problem 1: Uneven light distribution

Cause: Lamps hung too high, wide spacing between fixtures, or insufficient lamp power.

Solution: Use a staggered hanging pattern instead of straight lines. Choose wide-angle LED lamps (≥120° beam angle). Add supplemental lights in corners to eliminate dark spots.

Problem 2: Sudden drop in egg production (excluding disease)

Possible causes: Shortened photoperiod due to timer failure, reduced light intensity from faulty lamps, or abrupt spectral changes after replacing bulbs.

Solution: Check timers and fixtures weekly. When replacing lights, phase in the new lamps over 1 week before a full switch. Keep photoperiod, intensity, and spectrum stable unless deliberately adjusted for growth stage.

Problem 3: Feather pecking or cannibalism in broilers

Causes: Excessive brightness (>10 Lux), too much blue light, or insufficient dark periods.

Solution: Reduce light intensity to 5–8 Lux. Shift spectrum toward red while reducing blue. Guarantee at least 4 continuous dark hours daily for rest.

Problem 4: High lighting costs

Solution: Upgrade to LED lamps to save up to 70% energy. Apply intermittent lighting cycles to reduce operating hours. Install smart controllers that adjust brightness automatically with daylight, lowering artificial light use during sunny hours.

Smart & Green Future of Poultry LED Lighting

The future of poultry lighting is moving beyond simple illumination. For large-scale farms, the next decade will be defined by smart integration and sustainable design.

(1) Smart upgrades

Light–climate–feed integration: Smart systems will connect lighting with temperature, humidity, and feed intake data. For example, during heat stress, the system can automatically dim lights to reduce metabolic load.

Targeted lighting: With cameras and sensors, farms may provide individualized light programs. Weak or sick birds could receive longer photoperiods to encourage feeding, while the rest of the flock follows standard cycles.

Data-driven management: Systems will log photoperiods, intensity, and production metrics like egg count or weight gain. AI analysis will then suggest or automatically apply optimized lighting schedules tailored to each flock’s performance.

(2) Green development

Energy efficiency: Research is pushing LED efficiency beyond 150 lumens per watt, cutting power costs further. Solar-assisted systems are likely to become viable for remote or off-grid farms.

Eco-friendly materials: Mercury-free, recyclable fixtures will become the industry standard, aligning with environmental regulations and farm sustainability goals.

Welfare-focused lighting: Welfare directives, especially in Europe, are driving adoption of sunrise–sunset simulation instead of abrupt on/off cycles. Such gradual transitions reduce stress and improve overall flock health.

As technology advances, poultry LED lighting will no longer be just about visibility—it will become a central tool for precision farming, sustainability, and animal welfare.

Conclusion: Poultry Lights as a High-Return Investment

For farmers, poultry lighting is not a background detail—it is a direct driver of production, welfare, and profitability. The right program can improve egg yield, shorten growth cycles, and reduce stress, while poor lighting undermines all of these.

Traditional lamps may seem affordable, but their high energy use, short lifespan, and limited control make them costly over time. By contrast, poultry LED lighting offers precise spectrum tuning, stable intensity, and smart automation that align with modern farm needs. It reduces electricity bills, lowers maintenance, and creates healthier conditions for layers, broilers, and breeders alike.

The path forward is clear: adopting poultry LED lighting is not just an upgrade—it is an investment in long-term performance, sustainability, and competitiveness. For farms aiming to maximize efficiency and prepare for future demands, switching to LED is the most practical and profitable decision today.

Related Product

FAQs

Q1: Which light is better for broilers?

A: La lumière blanche (LED à spectre complet) est optimale pour les poulets de chair. Elle améliore la consommation d'aliments, la croissance musculaire et la prise de poids de 8 à 10 % par rapport à la lumière rouge. La lumière blanche assure également un indice de conversion alimentaire constant (ICA de 1,6 contre 1,8 sous lumière rouge).

Q2 : Pourquoi la lumière rouge produit-elle des œufs plus petits ?

A : La lumière rouge peut déclencher prématurément la libération d'ocytocine, raccourcissant ainsi la durée de la formation du vitellus. Cela réduit le poids des œufs après 30 semaines. Pour compenser, il est conseillé d'ajouter de la lumière verte (5 lux) aux zones de nidification afin d'améliorer le métabolisme du calcium et la qualité de la coquille.

Q3 : La lumière rouge améliore-t-elle la production d’œufs chez les poules pondeuses ?

R : Oui, la lumière rouge (660 nm) accélère la maturation sexuelle et augmente le nombre d'œufs sur le long terme (18 à 60 semaines) en stimulant les hormones reproductives. Cependant, les œufs exposés à la lumière rouge sont systématiquement plus légers que ceux exposés à la lumière blanche ou verte, surtout après 30 semaines.

Pour la qualité des œufs, la lumière verte est supérieure à la lumière rouge, produisant des coquilles plus épaisses et plus résistantes.

Q4 : Comment la lumière rouge affecte-t-elle le comportement des poulets ?

A : La lumière rouge réduit le stress grâce à sa longueur d'onde plus longue (660 nm), ce qui perturbe très peu les rythmes circadiens. Elle favorise les comportements passifs (repos, lissage des plumes) et diminue l'agressivité au sein des groupes.

En revanche, la lumière bleue augmente l'anxiété chez les volailles (par exemple, halètement, regroupement chez les canards), tandis que la lumière blanche maintient la stabilité comportementale.

_thumb.jpg)