家禽の照明は生産と成長にどのような影響を与えるのでしょうか?

目次

現代の農場にとってなぜ養鶏用照明が不可欠なのでしょうか?

養鶏場に設置されている照明は、作業員の利便性のためだと誤解している人が多いようです。しかし実際には、養鶏場の照明は鳥の生態に直接影響を与えます。

鶏などの家禽は、紫外線を含む人間よりも広い光スペクトルを感知し、その成長と繁殖は光信号と密接に結びついています。光の持続時間、強度、スペクトルは、視床下部-下垂体-性腺系を介したホルモン分泌に影響を与え、卵子の生産、成長、そして繁殖能力を制御します。

閉鎖型または大規模養鶏場では、自然光が不安定、あるいは全く届かない場合があります。適切な人工照明がないと、採卵鶏の産卵率が低下し、ブロイラーは発育にムラが生じ、種鶏は繁殖力が低下する可能性があります。そのため、効果的な照明は必須であり、生産性の向上、安定した群れの行動、そして飼料効率の向上を保証する重要な管理ツールです。

家禽照明の主要パラメータの説明

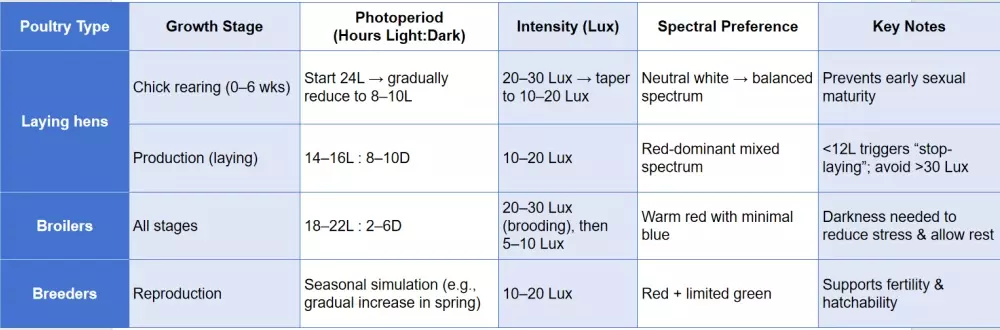

鶏舎用のLED照明は 、単にランプのオンオフを切り替えるだけではありません。光周期、強度、スペクトル、リズムという4つの技術的要素が連携して、鳥の成長、行動、そして生産性に影響を与えます。

以下では、産卵鶏、ブロイラー、種鶏のさまざまなニーズに焦点を当てながら、簡単に説明します。

1. 光周期 – 「ライトはどのくらいの時間点灯しておくべきですか?」

毎日の光への曝露時間は、鳥の成長と繁殖周期に直接影響します。養鶏業者は、鳥の種類と成長段階に応じてスケジュールを調整する必要があります。

(1)産卵鶏:

産卵期:14~16時間の連続点灯が必要です(例:16L:8D)。点灯時間が12時間未満(冬季など)になると、鶏は「産卵停止」の信号を受け取ります。

雛の飼育(0~6週):照明時間を24時間から8~10時間に徐々に減らします。これにより、鶏が早期に成熟するのを防ぎます。

(2)ブロイラー(肉用鶏):

生涯を通じて18~22時間の光を必要とします。日照時間が長いと摂食時間が長くなり、体重増加につながります。しかし、休息とストレス軽減のためには、少なくとも2~4時間の暗闇が不可欠です。

(3)ブリーダー:

照明スケジュールは自然の季節変化を模倣する必要があります。日照時間を徐々に長くすることで、繁殖力と産卵率が向上します。

よくある間違い:「長いほど良い」と考えること。例えば、採卵鶏に20時間以上の光を与えると、鶏にストレスを与え、繁殖力と産卵量が低下します。

2. 光の強さ – 「どれくらい明るくするべきか?」

光の強さはルクス(1ルクスは曇り空の室内の明るさに相当)で測定されます。鶏の飼育段階や種類によって必要な照度は異なります。

(1)育雛期(0~2週間):20~30ルクス。明るい光は雛が餌や水を素早く見つけるのを助け、早期死亡率を低下させます。

(2)産卵鶏(生産期):10~20ルクス。光が強すぎる場合(30ルクス超)、鶏は落ち着きを失い、羽つつきなどの有害な行動を示す。光が弱すぎる場合(5ルクス未満)、飼料摂取量と産卵量が減少する。

(3)ブロイラー(肥育期):5~10ルクス。明るさを低くすることで、鶏は落ち着き、運動によるエネルギーの浪費が減り、急速な体重増加が促されます。

実用的なヒント:家全体に光が均等に届くようにする必要があります。暗い隅(3ルクス未満)やホットスポットを避けてください。バランスを取るために、吊り下げる高さ(地上2~3メートル)とランプの間隔(2~3メートル間隔)を調整してください。

3. スペクトル含有量 – 「どの色が最も重要ですか?」

近年、家禽照明の研究ではスペクトルの最適化に重点が置かれており、「白色光であれば何でも良い」という古い考えに挑戦しています。

従来の白熱電球は暖色系(赤色優勢)の光に、蛍光灯は寒色系(青色優勢)の光に傾いています。しかし、どちらもスペクトル範囲が限られているため、家禽のニーズに正確に応えることはできません。

対照的に、LED スペクトルはカスタマイズ可能で、各波長が異なる役割を果たします。

l 赤色光(620~660 nm)は、鶏の産卵を促進し、ブロイラーの体重増加を加速します。

青色 光(450~495 nm)はブロイラーの活動を抑制しますが、ストレスを引き起こす可能性があります。

緑色 光(520~560 nm)は卵の重量増加に役立ちます。

UV -A(320~400 nm)はビタミンD3の合成をサポートしますが、慎重な制御が必要です。

実際には、産卵鶏舎では赤色の波長が中心の混合光が推奨されますが、ブロイラー鶏舎では青色の含有量が少ない暖色系の赤色光を優先する必要があります。

4. 光のリズム – 「連続か断続か?」

照明スケジュールは連続的またはサイクルに分割できます。

(1)連続点灯:

例:

16時間連続。シンプルですが、エネルギー消費量が多く、鳥の疲労も大きくなります。

(2)断続照明:

例:

レイヤー: 2 時間明るい / 2 時間暗い (繰り返し)。

ブロイラー: 1 時間明期 / 3 時間暗期 (繰り返し)。

断続的なリズムの利点:

30~50%のエネルギーを節約します。

鳥に休息を与え、ストレスと攻撃性を軽減します。

研究によれば、連続光に比べて産卵率がわずかに向上する可能性があるそうです。

重要事項:リズムは一定に保つ必要があります。頻繁な変化は概日リズムを乱し、群れにストレスを与えます。

要するに:

これらのパラメータを正しく適用すると、照明は単なる実用品から家禽のパフォーマンスを高める強力なツールへと変化します。

「伝統的なランプ」から「スマート照明」へ

養鶏における照明技術は、過去数十年で劇的に変化しました。それぞれの段階で進歩がもたらされましたが、同時に限界も生まれています。それが、養鶏場が現在LEDやスマートシステムへと移行している理由です。

白熱電球はかつて標準的な照明器具でした。スペクトルが自然光に近く、初期費用も低かったからです。しかし、エネルギーの大部分を熱として無駄にし、寿命も約1,000時間しかなく、現代の大規模住宅には不向きです。そのため、今でも実用的と言えるのは、狭い裏庭や一時的な設置に限られています。

蛍光灯は白熱灯に比べてエネルギー消費量が少なく、より明るい光を提供しました。しかし、蛍光灯はスペクトル出力が固定されており、水銀を含み、寿命は通常約8,000時間です。移行期には多くの中規模農場で導入されましたが、環境への配慮とスペクトル制御の限界により、今日ではその価値は限定されています。

LED照明は今や主流の選択肢となっています。消費電力を最大70%削減し、5万時間以上稼働し、ブロイラー、レイヤー、種鶏など、鶏種鶏に合わせてスペクトル設計をカスタマイズできます。また、水銀を含まず、環境にも優しい照明です。初期費用は高額ですが、長期的な性能と効率性を考えると、LEDは集約型鶏舎にとって最も費用対効果の高い選択肢です。

最新の取り組みはスマートLEDシステムです。効率性の向上に加え、アプリや中央管理ソフトウェアによる遠隔制御、日長の自動スケジュール設定、温度・湿度の気象センサーとの連携などが可能になります。これらのシステムは照明プログラムを動的に調整し、最小限の手動操作で最適な生育と繁殖を実現します。初期費用と専門家による設置は高額ですが、精密な管理を目指す現代の農場にとって、スマート照明は比類のないメリットをもたらします。

様々な家禽の種類に合わせた照明プラン

照明戦略は「画一的」であってはなりません。家禽の種類によって光に対する反応は異なるため、生産者は採卵鶏、ブロイラー、種鶏それぞれに適した照明プログラムを適用する必要があります。

(1)産卵鶏(レイヤー)

光周期: 生産期間中は 16 時間の光 (例: 5:00~21:00)、休止期間中は 8 時間の光。

強度: 家全体に均等に 15 ルクスを照射します。10 ルクス未満の影になる角は避けてください。

スペクトル: 赤と青の比率は 3:1 (約 660 nm の赤 + 450 nm の青)、カルシウムの吸収と殻の強度を高めるために UV-A の露出を制限 (1 日 1 ~ 2 時間)。

リズム: 断続的なサイクル (2 時間明るい + 2 時間暗い) は、ストレス行動を減らしながらエネルギーを節約するのに役立ちます。

卵生産のための鶏小屋の照明についての詳細をご覧ください。

(2)ブロイラー(肉用鳥)

Photoperiod: 24 h light in the brooding phase (0–2 weeks), then 20 h light + 4 h dark from week 3 onward (e.g., 6:00–2:00).

Intensity: 25 Lux during brooding to encourage feeding and drinking; reduce to 8 Lux in the grow-out phase to limit activity and improve feed conversion.

Spectrum: Dominantly red (≈70% at 660 nm) with minimal blue (<10%) to minimize stress.

Rhythm: Continuous light early, then switch to intermittent cycles (1 h light + 3 h dark) to balance growth and rest.

(3) Breeders

Photoperiod: Seasonal simulation—gradually extend daylight hours from 12 to 16 as in spring.

Intensity: 15–20 Lux, strong enough to support activity but not excessive, which could disrupt mating.

Spectrum: Broad-spectrum lighting (red, green, blue) to mimic natural daylight and stimulate breeding behaviors.

Rhythm: Continuous light during the active phase to maintain consistent mating patterns.

When applied correctly, these tailored lighting programs improve performance, welfare, and efficiency across all poultry houses.

5. Common Problems in Poultry Lights and Solutions

Even with well-planned programs, lighting issues often appear in daily farm management. Below are the most frequent problems and actionable poultry lighting solutions.

Problem 1: Uneven light distribution

Cause: Lamps hung too high, wide spacing between fixtures, or insufficient lamp power.

Solution: Use a staggered hanging pattern instead of straight lines. Choose wide-angle LED lamps (≥120° beam angle). Add supplemental lights in corners to eliminate dark spots.

Problem 2: Sudden drop in egg production (excluding disease)

Possible causes: Shortened photoperiod due to timer failure, reduced light intensity from faulty lamps, or abrupt spectral changes after replacing bulbs.

Solution: Check timers and fixtures weekly. When replacing lights, phase in the new lamps over 1 week before a full switch. Keep photoperiod, intensity, and spectrum stable unless deliberately adjusted for growth stage.

Problem 3: Feather pecking or cannibalism in broilers

Causes: Excessive brightness (>10 Lux), too much blue light, or insufficient dark periods.

Solution: Reduce light intensity to 5–8 Lux. Shift spectrum toward red while reducing blue. Guarantee at least 4 continuous dark hours daily for rest.

Problem 4: High lighting costs

Solution: Upgrade to LED lamps to save up to 70% energy. Apply intermittent lighting cycles to reduce operating hours. Install smart controllers that adjust brightness automatically with daylight, lowering artificial light use during sunny hours.

Smart & Green Future of Poultry LED Lighting

The future of poultry lighting is moving beyond simple illumination. For large-scale farms, the next decade will be defined by smart integration and sustainable design.

(1) Smart upgrades

Light–climate–feed integration: Smart systems will connect lighting with temperature, humidity, and feed intake data. For example, during heat stress, the system can automatically dim lights to reduce metabolic load.

Targeted lighting: With cameras and sensors, farms may provide individualized light programs. Weak or sick birds could receive longer photoperiods to encourage feeding, while the rest of the flock follows standard cycles.

Data-driven management: Systems will log photoperiods, intensity, and production metrics like egg count or weight gain. AI analysis will then suggest or automatically apply optimized lighting schedules tailored to each flock’s performance.

(2) Green development

Energy efficiency: Research is pushing LED efficiency beyond 150 lumens per watt, cutting power costs further. Solar-assisted systems are likely to become viable for remote or off-grid farms.

Eco-friendly materials: Mercury-free, recyclable fixtures will become the industry standard, aligning with environmental regulations and farm sustainability goals.

Welfare-focused lighting: Welfare directives, especially in Europe, are driving adoption of sunrise–sunset simulation instead of abrupt on/off cycles. Such gradual transitions reduce stress and improve overall flock health.

As technology advances, poultry LED lighting will no longer be just about visibility—it will become a central tool for precision farming, sustainability, and animal welfare.

Conclusion: Poultry Lights as a High-Return Investment

For farmers, poultry lighting is not a background detail—it is a direct driver of production, welfare, and profitability. The right program can improve egg yield, shorten growth cycles, and reduce stress, while poor lighting undermines all of these.

Traditional lamps may seem affordable, but their high energy use, short lifespan, and limited control make them costly over time. By contrast, poultry LED lighting offers precise spectrum tuning, stable intensity, and smart automation that align with modern farm needs. It reduces electricity bills, lowers maintenance, and creates healthier conditions for layers, broilers, and breeders alike.

The path forward is clear: adopting poultry LED lighting is not just an upgrade—it is an investment in long-term performance, sustainability, and competitiveness. For farms aiming to maximize efficiency and prepare for future demands, switching to LED is the most practical and profitable decision today.

Related Product

FAQs

Q1: Which light is better for broilers?

A:ブロイラーには白色光(フルスペクトルLED)が最適です。赤色光と比較して、飼料摂取量、筋肉の成長、体重増加が8~10%向上します。また、白色光は飼料要求率(FCR)の安定化にも役立ちます(赤色光ではFCRが1.8であるのに対し、白色光では1.6)。

Q2: 赤い光が小さい卵を生み出すのはなぜですか?

A:赤色光はオキシトシンの放出を早期に引き起こし、卵黄の産卵期間を短縮させる可能性があります。これにより、30週以降は卵重が減少します。カルシウム代謝と卵殻の質を向上させるために、営巣エリアに緑色光(5ルクス)を追加することで、この現象を補うことができます。

Q3: 赤色光は産卵鶏の卵生産を改善しますか?

A:はい、赤色光(660 nm)は生殖ホルモンを刺激することで性成熟を促進し、長期使用(18~60週)で卵子数を増加させます。ただし、赤色光照射下での卵子は、白色光や緑色光照射下と比較して、特に30週以降は重量が小さくなります。

卵の品質に関しては、緑色光は赤色光よりも優れており、より厚く丈夫な卵殻を生み出します。

Q4: 赤色光は鶏の行動にどのような影響を与えますか?

A:赤色光は波長が長い(660nm)ため、概日リズムの乱れを最小限に抑え、ストレスを軽減します。受動的な行動(休息、羽繕い)を促進し、群れの攻撃性を軽減します。

対照的に、青色光は家禽の不安(例えば、あえぎ、アヒルの群れ)を増大させますが、白色光は行動の安定性を維持します。

_thumb.jpg)