Photoperiod Management in Cattle Barns

The Necessity of Photoperiod Management for Dairy Cows

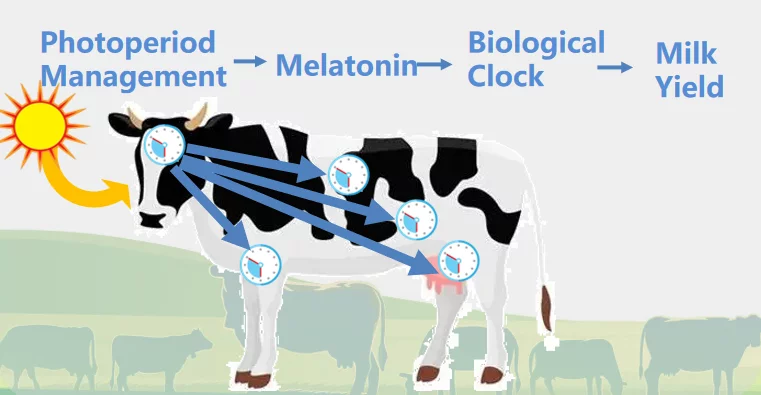

Periodic lighting changes regulate animals’ biological rhythms and directly influence growth, productivity, and reproduction. Light signals are transmitted through the eyes to the hypothalamus, where they regulate melatonin and gonadotropic hormone secretion. Proper lighting suppresses melatonin, thereby activating feed intake, metabolism, and lactation functions.

The Scientific Principles of Light Exposure on Dairy Cows

1. Key Effects:

1). Stimulates feed intake: Optimizes melatonin rhythms and increases appetite

2). Increases milk yield: Enhances mammary development and lactation efficiency

3). Improves overall health: Supports skeletal growth and nutrient absorption

2. Application Value:

Scientifically designed lighting programs directly improve productivity and operational efficiency.

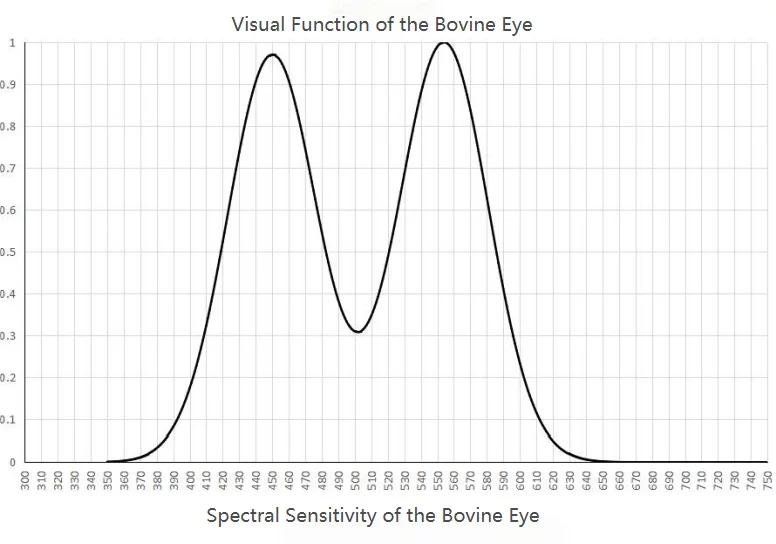

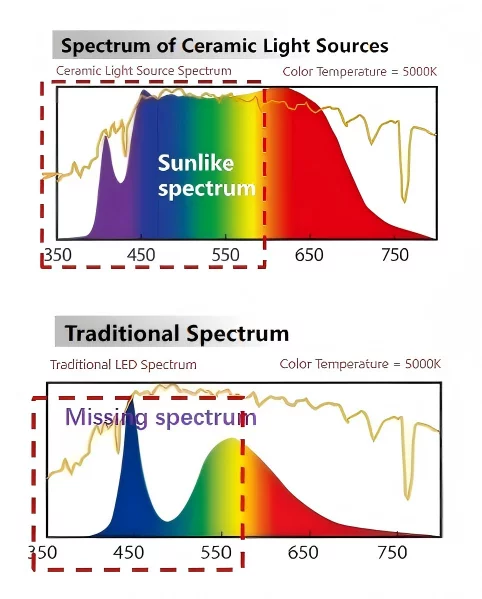

Based on 24 years of experimental research, dairy cattle are dichromatic animals, primarily sensitive to blue and green light and minimally responsive to red light. Continuous full-spectrum (sunlight-like) lighting synchronizes circadian rhythms and promotes vitamin D3 synthesis, strengthening bones and reducing the risk of lameness and osteoporosis.

3. Key Findings:

1). 16–18 hours of extended lighting vs. natural daylight (8–13.5 h, ≤70 lx)

2). Milk yield increased by 5–16% (average ~8%, ≈ +2 kg/day)

3). Feed intake increased by 6%

4). Response time: 2–4 weeks

Conclusion:

Research confirms that properly regulating melatonin suppression and secretion directly stimulates feed intake and is a key mechanism for increasing milk production in dairy cattle.

.webp)

The Scientific Principles of Lighting Impact on Dairy Cows

Effective livestock lighting starts with proper photoperiod management. Inappropriate lighting alone cannot deliver sustained productivity gains; optimal results require a combination of correct light cycles, fixture specifications, and professional lighting design.

Cattle have a 330° ultra-wide field of view and dichromatic vision (similar to red–green color blindness), with limited depth perception but high sensitivity to motion. Their visual spectrum ranges from 370–650 nm, with strong sensitivity to blue and green light. Cattle also respond to UVA light (370–400 nm), while showing low sensitivity to red light and a sensitivity trough in the 495–525 nm range.

Features and Advantages of Photoperiod Management

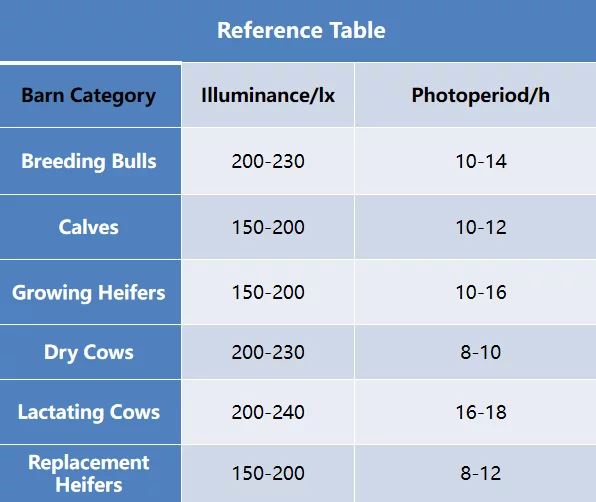

Different types and stages of cattle have varying requirements for light duration. The left diagram shows a reference table for light intensity and photoperiod in cattle barns (requires inclusion of light decay data during the usage period).

Scientific barn photoperiod management can increase milk yield by an average of 8% (up to 5–16%) and reduce overall lighting energy consumption by 30%+ under equivalent illumination levels. Fully automated systems can operate continuously for long periods, reducing labor requirements and supporting low-carbon, sustainable dairy production while delivering strong economic and social benefits.

Lighting Requirements for Photoperiod Management in Cattle Barns

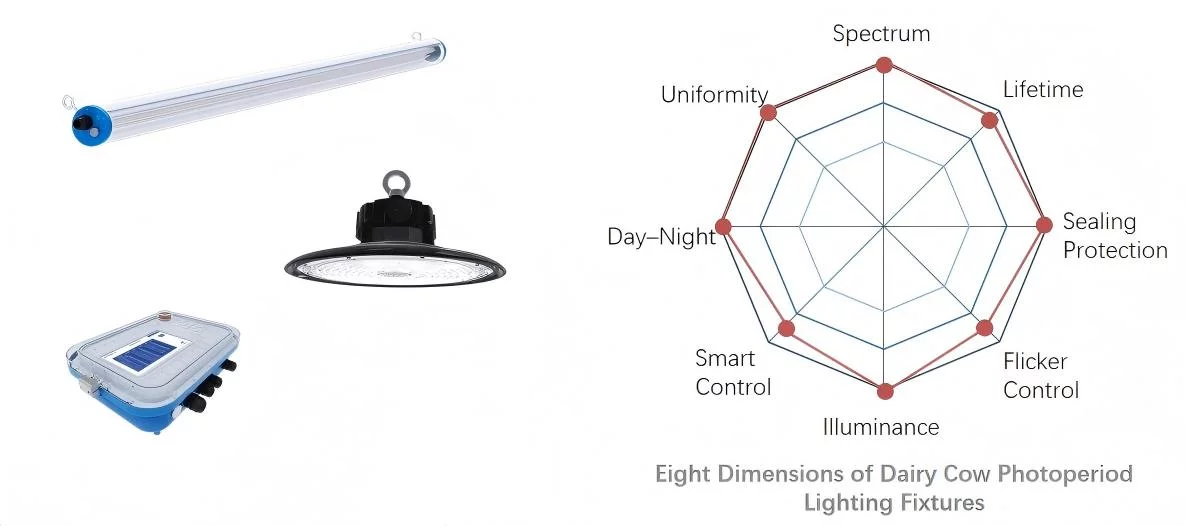

Effective dairy barn lighting goes beyond illuminance alone. Photoperiod lighting must be evaluated across eight key dimensions, including spectrum, uniformity, reliability, and intelligent control. Proper spectrum and photoperiod management regulate melatonin, stimulate feed intake, and support stable milk production, while uniform, flicker-free illumination reduces stress and improves animal comfort. At the system level, long lifetime, high sealing performance, and smart day–night control ensure reliable operation in harsh barn environments, enabling efficient, automated, and sustainable dairy production.

Spectrum in Dairy Cow Photoperiod Management

Due to dichromatic vision, cattle have limited visual resolution for certain objects. Colors such as yellow and blue appear less vivid to cattle, with perception dominated by shades of gray and black. Although the bovine visual system exhibits two spectral sensitivity peaks, continuous-spectrum lighting delivers a more balanced and biologically effective visual response.

Research indicates that effective regulation of melatonin secretion in dairy cattle requires specific spectral stimulation, with continuous, sunlight-like spectra producing optimal results. A spectrum closer to natural sunlight supports endogenous vitamin D3 synthesis, enhances animal comfort, and promotes overall health, ultimately contributing to the production of high-quality, healthy milk.

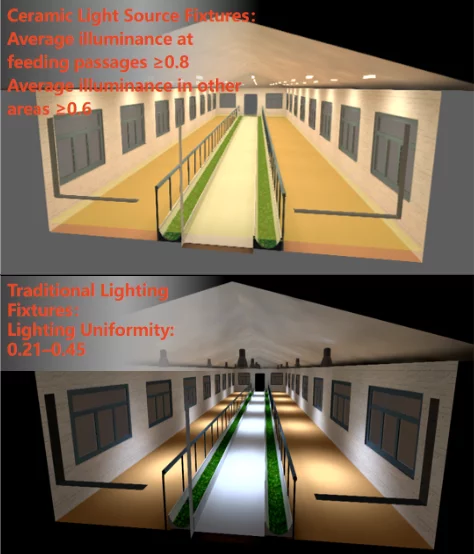

Uniform Lighting of Photoperiod Management

Effective photoperiod management for dairy cattle requires highly uniform illumination. Due to limited depth perception and poor stereoscopic vision, dairy cows are sensitive to uneven lighting conditions. Pronounced light–dark contrasts within the barn can cause stress and anxiety, negatively affecting milk production.

To eliminate light–dark alternation in dairy barns, scientific optical distribution and lighting design are essential. Through barn-specific lighting simulations and calculations, uniform light levels can be ensured across the floor area, avoiding sharp illuminance variations.

Illuminance uniformity is therefore a critical performance indicator in dairy barn lighting systems and a key factor in maintaining animal comfort and stable productivity.

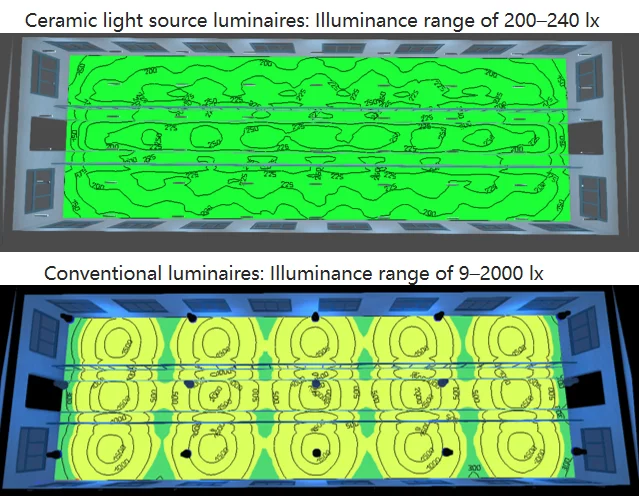

Illuminance of Photoperiod Management

Research indicates that illuminance levels in lactating cow feed alleys must be maintained at 200–240 lux to effectively suppress melatonin rhythms. Illuminance levels that are too high or too low fail to produce the desired biological response and do not deliver optimal production outcomes.

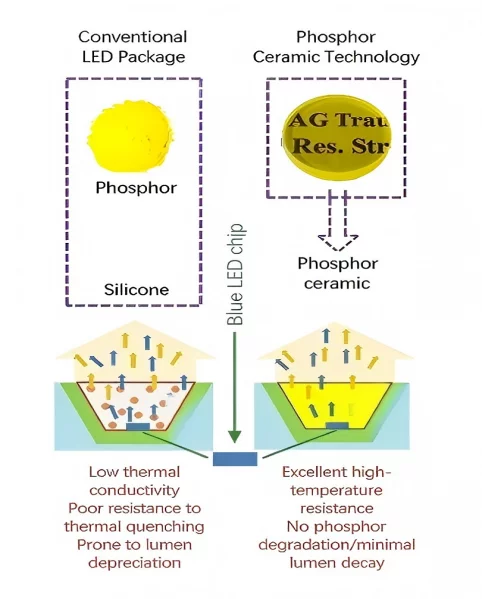

Lumen Maintenance Requirements and Phosphor Stability in Photoperiod Lighting

For photoperiod management lighting, under specified operating conditions, the lumen maintenance must not fall below 70% at 50,000 hours, corresponding to a normal service life of approximately 5 years.

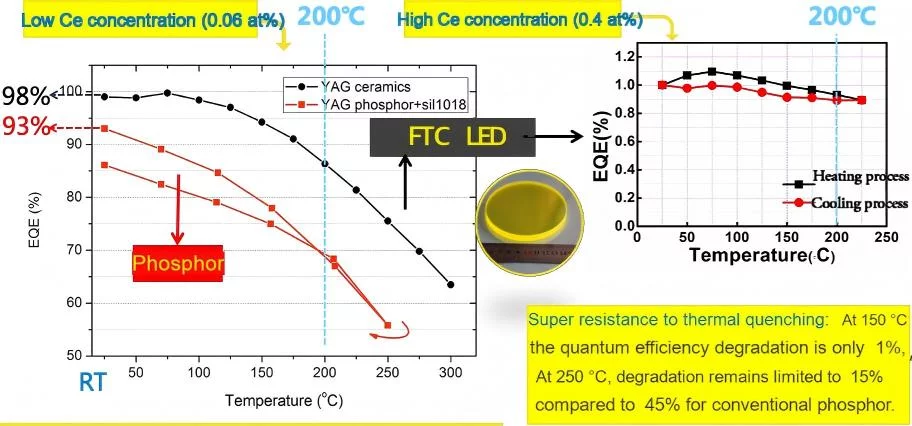

Based on our long-term research, lumen maintenance of light sources is primarily determined by the thermal quenching characteristics of the phosphor conversion materials. One of the key reasons for the rapid lumen depreciation of conventional LED light sources is the thermal degradation and failure of these phosphor conversion materials.

White LED Emission Principle:

White light is generated when a blue LED chip excites phosphor conversion materials, which emit yellow–green light. This emitted light mixes with the remaining unconverted blue light to produce white light.

Thermal Quenching Comparison Test: Phosphor vs. Fluorescent Ceramic

Phosphor ceramics exhibit exceptional resistance to thermal quenching. At 150 °C, the quantum efficiency degradation is only −1% (compared to −22% for conventional phosphor). At 200 °C, lumen degradation is −7% (vs. −35% for phosphor), and at 250 °C, degradation remains limited to −15% (vs. −45% for phosphor).

These results demonstrate the superior high-temperature stability and lumen maintenance performance of phosphor ceramic materials under extreme thermal conditions.

Harmful Gases in Dairy Barns

The air within dairy barns contains various harmful gases, including ammonia (NH₃), hydrogen sulfide (H₂S), carbon dioxide (CO₂), and methane (CH₄), which pose risks to animal health, productivity, and operational safety. The following are the primary harmful gases found in cattle barns:

1). Ammonia (NH₃)

Source: Digestive breakdown of feed and manure

Impact: Reduced feed intake and productivity; risk of chronic toxicity

2). Hydrogen Sulfide (H₂S)

Source: Decomposition of sulfur-containing organic matter in feed and manure

Impact: Decreased disease resistance and increased susceptibility to various illnesses

3). Methane (CH₄)

Source: Rumination and eructation (belching)

Impact: Increased risk of safety hazards

4). Carbon Dioxide (CO₂)

Source: Rumination and eructation

Impact: Causes hypoxia, reduced appetite, and chronic toxic effects

.webp)

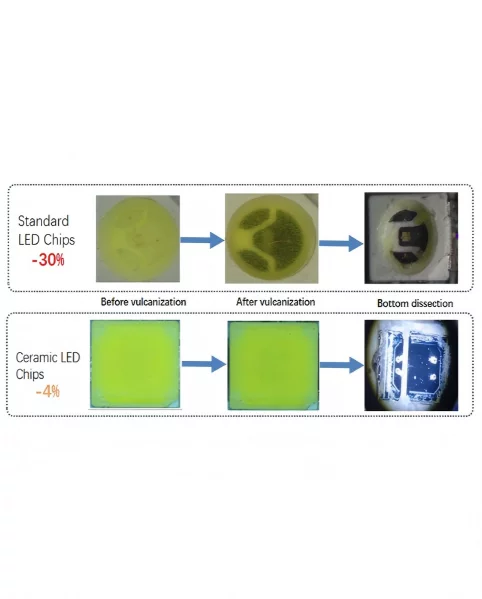

Why Conventional LEDs Fail in Sulfur-Rich Environments

Conventional LED light sources are highly vulnerable to sulfur corrosion due to their silicone-encapsulated phosphor packaging. Sulfur-containing gases can penetrate the porous silicone and phosphor layers, reacting with the silver-plated reflective layer and causing sulfidation.

Once sulfidation occurs, the reflective silver layer darkens and becomes light-absorbing, leading to lumen depreciation and correlated color temperature (CCT) shift. Furthermore, silver sulfide exhibits increased electrical conductivity at elevated temperatures, significantly increasing the risk of leakage current during operation. In severe cases, gold wire bond detachment at solder joints may occur, resulting in open-circuit failure and complete luminaire outage.

In contrast, Ceramiclite products demonstrate a clear advantage in sulfur-resistance performance compared to conventional light sources, offering significantly higher reliability in harsh, sulfur-rich environments.

Lumen Maintenance vs. Time — Comparative Trend Analysis

Test results confirm that fluorescent transparent ceramic materials can withstand heated aqua regia corrosion, demonstrating excellent chemical stability. In H₂S mixed-gas corrosion tests, ceramic light sources maintain stable lumen output over time, while conventional light sources show rapid degradation. This proves the superior corrosion resistance and long-term reliability of ceramic light source technology in harsh environments.

.webp)

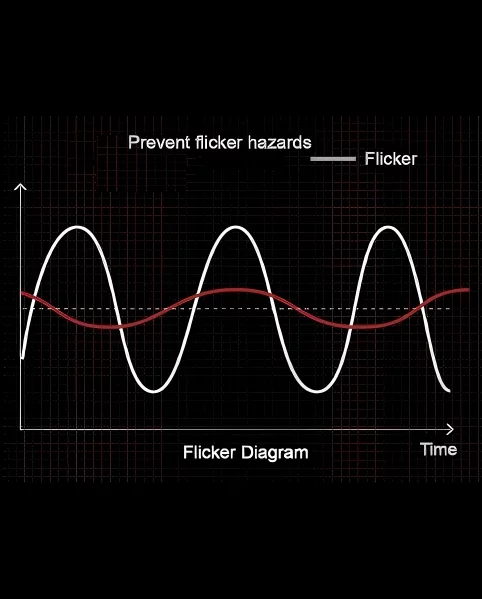

Flicker Control of Photoperiod Lighting

Flicker refers to the periodic fluctuation of luminous flux in electric light sources. Although dairy cattle are not highly sensitive to stereoscopic vision, their unique ocular structure makes them significantly more sensitive to flicker than humans, allowing them to perceive fluctuations invisible to the human eye. Research and practical experience indicate that flicker depth for dairy cattle should be strictly controlled to ≤3%, which is more stringent than the ≤5% limit typically applied to indoor lighting for humans, as excessive flicker can trigger stress responses and reduce milk yield.

To eliminate this risk, a constant-current 0–10 V dimming driver is employed, enabling smooth, flicker-free brightness adjustment from 0–100% across the entire dimming range. Sudden on/off switching may induce stress; therefore, a 15–30 minute gradual dimming transition is recommended to simulate natural light changes.

Due to their higher visual sensitivity and limited pupil adaptation, cattle are particularly responsive to rapid light fluctuations. Strict flicker control is essential to prevent stress, anxiety, reduced feed intake, and decreased milk production.

Sealing Performance of Photoperiod Lighting

The luminaire features a fully sealed design compliant with IP67 and IP69K protection ratings. IP67 ensures complete dust tightness and resistance to water immersion up to 1 meter for 30 minutes, while IP69K provides full dust protection and withstands high-pressure, high-temperature water jet cleaning.

The fixture can be directly cleaned using high-pressure water jets under the following conditions: water pressure of 8,000–10,000 kPa and **water temperature of 80 ± 5 °C, ensuring reliable operation and hygiene in demanding dairy barn environments.

Intelligent Circadian Control in Photoperiod Management

Circadian Rhythm: The circadian rhythm is the physiological mechanism of the “biological clock,” representing an approximately 24-hour cycle from day to night that regulates critical functions such as metabolism, sleep–wake cycles, heart rate, and blood pressure. Light is the most important time-setting cue (zeitgeber), with periodic natural daylight synchronizing biological rhythms to the Earth’s 24-hour rotation.

Dynamic Rhythm Control: A dynamic circadian algorithm simulates local sunrise and sunset patterns, controlling the on/off schedule of photoperiod management luminaires. The system automatically adjusts illuminance and spectral composition to support optimal circadian regulation.

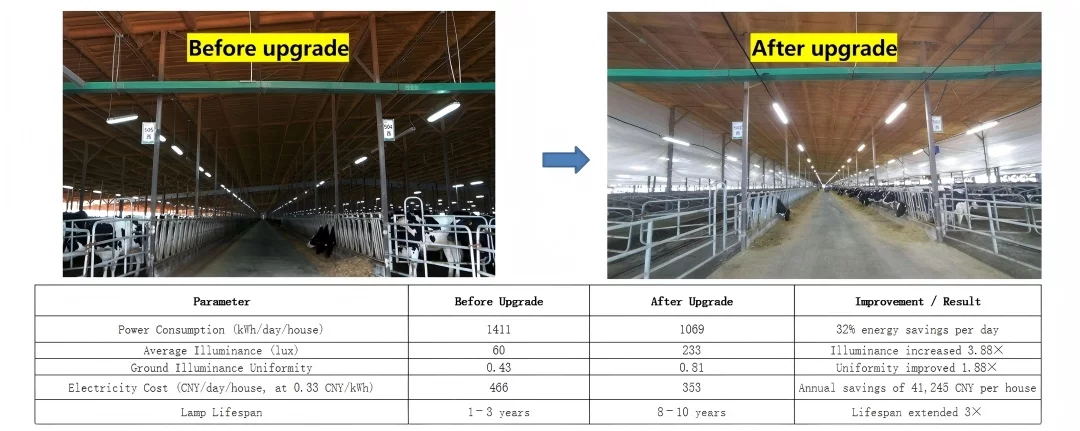

Case Study: Lighting System Upgrade at a Dairy Farm

Lighting System Solution for a Dairy Group's Ranch

After upgrade: average illuminance increased nearly 4×, illuminance uniformity nearly 2×, energy savings 32%, lamp lifespan extended over 3× under high humidity, high sulfur, and high ammonia conditions.

Applied Products

Designed for optimal barn lighting, the T21 LED barn light provides >240 lux average illuminance with ≥0.8 uniformity, ensuring consistent, high-quality light for livestock.

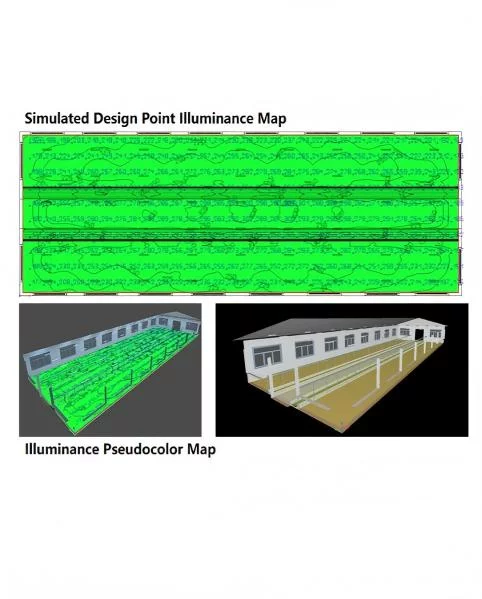

Simulated illuminance maps and 3D visualizations confirm uniform coverage and effective fixture layout.

Key Features:

a. High uniformity lighting for animal welfare

b. Optimized illuminance for operational efficiency

c. Verified through simulation and visualization

Thanks for your enquiry, we will contact ASAP.

Something went wrong...

_thumb.jpg)