Do Poultry Farms Really Need Chicken Coop Lighting?

.jpg)

Quick Reference: Chicken Coop Lighting Essentials

Chicken coop lighting is essential in modern poultry management. It helps hens maintain consistent laying cycles, especially during short winter days.

| Aspect | Recommended Practice |

|---|---|

| Photoperiod | 14–16 hours/day for layers; maintain stable schedule |

| Spectrum | Red light for reproduction; full-spectrum LED for balance; blue/green for welfare |

| Light Intensity | 10–20 lux at feeder/nest height |

| Uniformity | Avoid hotspots/shadows; ensure even illumination |

| Fixture Type | Flicker-free, dimmable LED chicken coop lights |

| Energy & Lifespan | LEDs: up to 60% energy savings; >50,000 hours lifespan |

Introduction: The Role of Chicken Coop Lighting

Chicken coop lighting is far more than a convenience for human visibility—it is a critical management tool that directly impacts hen welfare, flock behavior, and egg production. Across commercial poultry operations, integrators and farmers increasingly recognize that hens respond to light differently than humans. Beyond brightness, the spectrum, duration, and intensity of light govern hens' circadian rhythm, feeding patterns, and reproductive cycles.

For poultry professionals, the question is no longer merely "Do we need chicken coop lighting?" but rather "How can we implement an optimized chicken coop lighting program that ensures consistent egg production and hen welfare year-round?" This article explores the science, practical strategies, and best practices for designing effective lighting systems for poultry facilities.

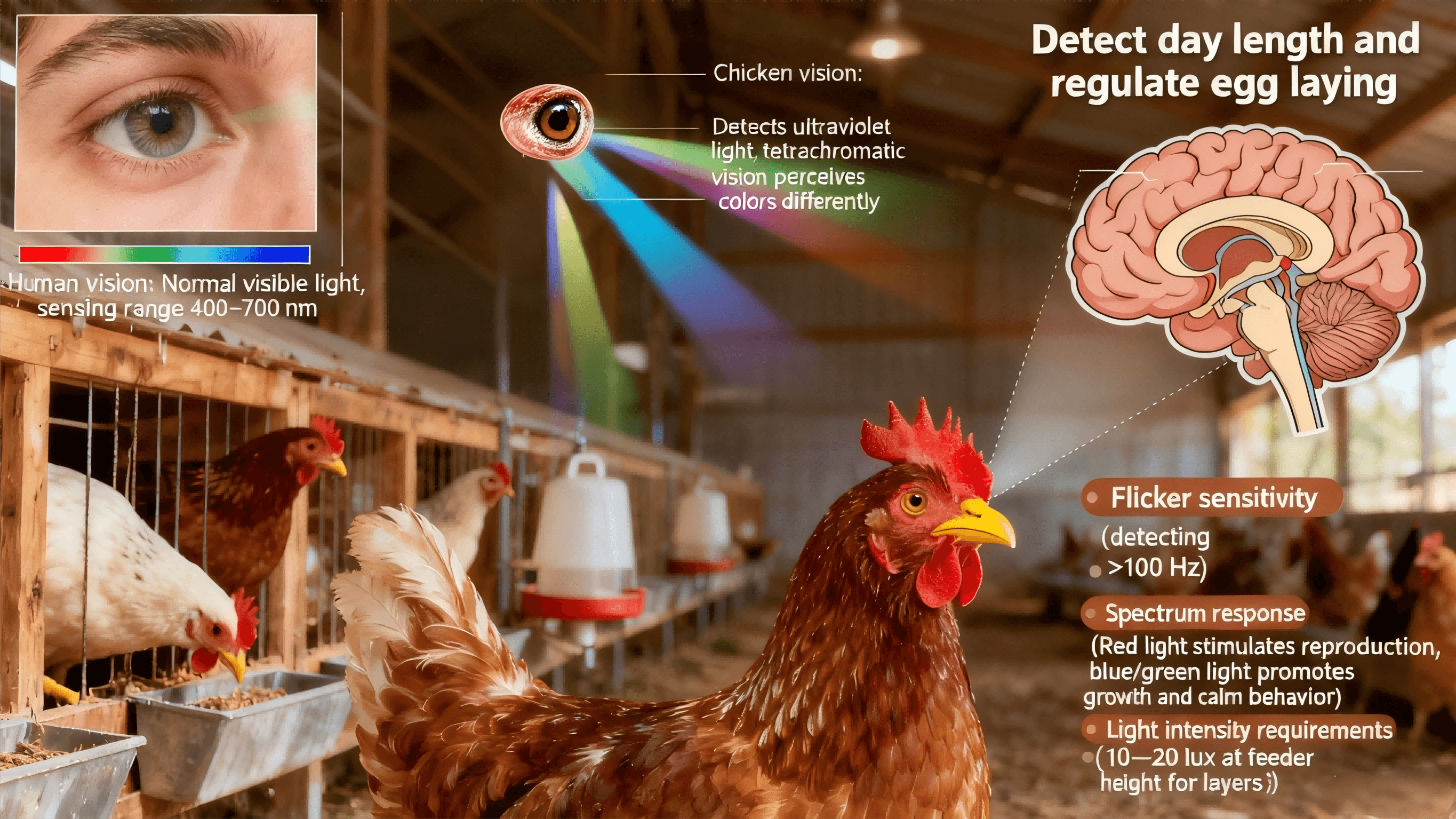

Understanding Poultry Vision and Light Sensitivity

Birds are biologically distinct from humans in how they perceive light. Chickens possess tetrachromatic vision, enabling them to detect ultraviolet (UV) wavelengths invisible to human eyes. Practically speaking, a light bulb that appears white to a farmer may be spectrally incomplete for a hen, impacting behavior and physiology.

Additionally, chickens have extraocular photoreceptors in the hypothalamus. These receptors sense day length and trigger hormonal responses that regulate egg laying. When daylight drops below approximately 12 hours during fall and winter, hens naturally reduce egg production unless artificial chicken coop lighting compensates for the shortfall.

Key biological sensitivities include:

Flicker Sensitivity: Chickens can detect flicker above 100 Hz, making high-frequency LED drivers essential.

Spectrum Response: Red light stimulates reproductive hormones; blue and green light influence growth and calming behavior.

Light Intensity: Layers require 10–20 lux at feeder height, whereas broilers thrive under lower intensities.

These factors underscore why chicken coop lighting programs must be poultry-centric rather than designed solely for human perception.

Natural Daylight vs. Artificial Chicken Coop Lighting

Natural sunlight provides full-spectrum illumination and seasonal cues, but it is unreliable for maintaining stable egg production year-round, particularly in temperate and northern climates. Artificial chicken coop light enables farmers to extend photoperiods, maintain flock consistency, and prevent seasonal drops in productivity.

| Lighting Source | Advantages | Limitations | Impact on Egg Production |

|---|---|---|---|

| Natural Sunlight | Full spectrum including UV; free energy | Inconsistent; short days in winter reduce laying | Seasonal fluctuation; egg output drops in fall/winter |

| LED Chicken Coop Lights | Programmable spectrum; energy-efficient; long lifespan; low heat | Initial cost; requires proper setup | Consistent year-round egg production; higher laying rates |

| Fluorescent Lighting | Historically affordable | Flicker issues; lower lifespan; hazardous materials | Moderate improvement; inferior to LEDs |

| Incandescent Lighting | Warm spectrum supports reproduction | Inefficient; high heat; short lifespan | Improves laying but economically outdated |

Studies (Poultry Science, Southern SARE) show that hens exposed to 14–16 hours of controlled artificial light maintain 5–15% higher laying rates than flocks relying solely on natural daylight.

How Chicken Coop Lighting Boosts Egg Production

Optimized chicken coop lighting for egg production directly influences hens' reproductive physiology through photoperiod control, spectrum optimization, and intensity management.

Photoperiod Control

Extending the light period to 14–16 hours per day signals the hypothalamus to stimulate ovulation. This is crucial for maintaining consistent egg production during short winter days when natural daylight can fall below 10 hours.

Spectrum Optimization

Different wavelengths affect birds in specific ways:

| Light Spectrum | Biological Effect | Egg Production Impact |

|---|---|---|

| Red (600–700 nm) | Stimulates reproductive hormones | Increases egg laying rates |

| Blue/Green (400–500 nm) | Calms birds; supports feed conversion | Improves welfare; indirectly supports production |

| Full-Spectrum LED | Mimics natural daylight | Balanced output; stabilizes laying; reduces stress |

Light Intensity and Uniformity

Uniform lighting ensures that all hens receive adequate illumination at feeder and nest box height. Uneven light can cause stress, aggression, and reduced laying performance. LED barn lights with carefully calculated beam angles prevent shadows and hotspots, supporting uniform egg production across the flock.

Energy Efficiency and Sustainability

Modern LED chicken coop lighting consumes up to 60% less energy than fluorescent or incandescent systems, with lifespans exceeding 50,000 hours. Reduced heat output also lowers ventilation demands, enhancing overall energy efficiency.

Practical Guidelines for Implementing Chicken Coop Lighting

Designing an effective lighting program involves strategic planning and attention to hen biology:

Gradual Introduction: Begin pullets with low light intensity (5–10 lux) to prevent premature sexual maturity.

Controlled Day Length: Gradually increase photoperiods as hens approach laying age.

Consistent Schedules: Avoid sudden changes in duration, spectrum, or intensity to reduce stress and prevent disruptions in egg production.

High-Quality LED Fixtures: Use flicker-free, dimmable LEDs to match poultry sensitivity.

Monitor Performance: Regularly check egg production metrics and adjust lighting programs based on flock response.

When implemented correctly, a chicken coop lighting system balances biology, technology, and economics, improving hen welfare and farm profitability.

Conclusion: Strategic Chicken Coop Lighting is Essential

Chicken coop lighting is not optional—it is a cornerstone of modern egg production. Properly designed artificial lighting compensates for seasonal daylight fluctuations, stabilizes laying performance, and allows precise control over poultry welfare. By combining optimized photoperiods, spectra, and intensity, farmers can ensure higher, more consistent egg production, healthier flocks, and energy-efficient operations.

For commercial poultry operations, investing in chicken coop lighting for egg production is one of the most effective strategies to maximize return, maintain flock health, and future-proof farm infrastructure.

_thumb.jpg)