Technical Specification Of Cattle Chute Lights

Table of Contents

Cattle-Centric Lighting Design

Technical Requirements for Cattle Chute Lights

Control & Efficiency of Cattle Lighting

Measurement & Compliance

Operational Benefits

Conclusion

Introduction:

The Technical Specification for Cattle Chute Lights (T/SZFAA 06-2021), issued by the Shenzhen Facility Agriculture Industry Association (SZFAA), provides scientifically based requirements for artificial lighting in cattle facilities. This standard sets out detailed criteria for cattle chute lights and commercial dairy light fixtures, ensuring that lighting design prioritizes animal biology, energy efficiency, and operational practicality.

When properly implemented, these lighting systems improve cattle welfare, reproduction, and productivity in dairy, beef, and breeding operations—making them an essential part of modern livestock management.

Cattle-Centric Lighting Design

Traditional lighting design metrics (e.g., lux, lumens) are human-oriented and insufficient for livestock. Cattle chute lights must be designed around bovine visual biology.

Key biological insights drive the standard:

Cattle Vision Spectrum:

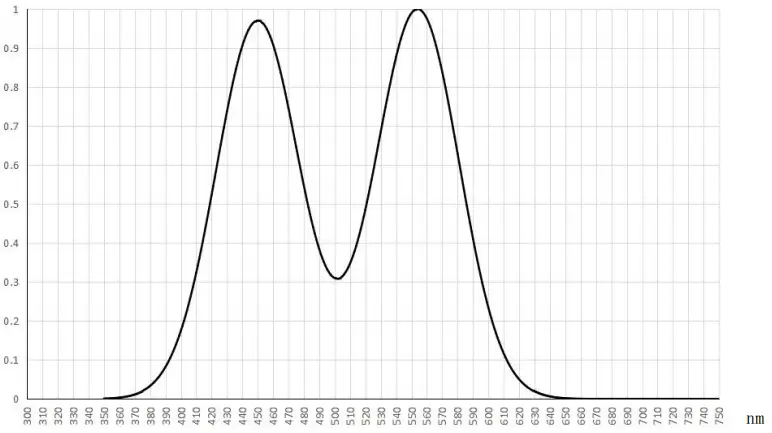

Cattle perceive light from 370–650 nm, with peak sensitivity at 450 nm (blue) and 554 nm (orange-yellow). They have poor detection of red light (>650 nm) and reduced sensitivity in the green range (495–525 nm).Cattle-Specific Lighting Metrics:

CaPF (Cattle Photon Flux): Total photon output (μmol/s, 370–650 nm)

CaPFD (Cattle Photon Flux Density): Photon density at target surfaces (μmol/m²·s)

CaQE (Cattle Quantum Efficiency): Energy-to-photon efficacy (≥1.5 μmol/J)

By focusing on these metrics, commercial dairy light fixtures can be evaluated for true biological effectiveness instead of relying only on human visual standards.

Technical Requirements for Cattle Chute Lights

High-quality cattle chute lights must adhere to strict technical requirements to ensure both animal welfare and long-term operational efficiency. One of the most critical aspects is spectral quality. Lighting systems should deliver a continuous spectrum within the 370–650 nm range, avoiding sharp or isolated spectral peaks that can disturb cattle vision.

For this reason, white LED fixtures with a color temperature between 3500K and 5500K are recommended as the primary spectrum source. In certain cases, supplemental red light can be used for human night inspection, but this should only be introduced when supported by scientific evidence to avoid disrupting cattle physiology.

Another important factor is photoperiod management. Research shows that a long-day photoperiod (LDPP) of more than 12 hours—typically 16 to 18 hours—is ideal for lactating cows, as it maximizes milk yield and improves feed intake. In contrast, dry cows benefit from a short-day photoperiod (SDPP) of fewer than 12 hours. To minimize stress, light transitions must be gradual, simulating natural dawn and dusk over 30 to 60 minutes. Sudden on/off cycles are strictly discouraged, as they can negatively impact cattle behavior and overall productivity.

Proper light distribution and uniformity are also essential in cattle facilities. Illumination at feeding troughs should reach a uniformity level of at least 0.8, measured across 1.5 m × 2 m areas, while general barn spaces should maintain a minimum of 0.7. To achieve this, light fixtures should provide a beam angle of at least 90°, ensuring even coverage without creating hotspots or shadows that may stress the animals.

.png)

In addition, flicker and photometric performance play a crucial role in cattle comfort and system reliability. Cattle chute lighting systems must have a flicker index of no more than 3% within frequencies of 125–250 Hz. They should also deliver stable performance over time, with photon flux maintenance of at least 70% at 50,000 operating hours and lumen output no lower than 90% of the rated initial value.

Finally, durability is a defining feature of high-performing commercial dairy light fixtures. All fixtures should carry a minimum ingress protection rating of IP66 to guard against dust and moisture, while areas subject to frequent cleaning, such as washdown zones, require IP69K-rated lights. The materials must resist corrosion from ammonia, nitrates, and salts, validated through a 200-hour salt spray test, and they should withstand prolonged exposure to 3% ammonia at 35°C for at least three months without degradation.

Control & Efficiency of Cattle Lighting

Efficient control systems make cattle chute lights not only effective but also cost-saving. A well-structured system should provide flexibility, precision, and durability.

Spectral and Intensity Modulation – Controllers must allow adjustments of spectrum and light intensity, ensuring lighting conditions are optimized for lactating, dry, or breeding cows.

Automated Photoperiod Programming – Scheduling features enable accurate day-length management, supporting both productivity and animal welfare.

Power Factor Standards – Fixtures must maintain ≥0.9 for >50W, ≥0.7 for 10–50W, and ≥0.5 for <10W systems to reduce energy loss.

Power Supply Efficiency – A minimum of 85% efficiency helps keep electricity costs low over the system's lifetime.

In summary, smart controls make commercial dairy light fixtures more than just lighting equipment—they become strategic tools for farm management.

Measurement & Compliance

For cattle chute lighting systems to deliver reliable results, strict measurement and compliance protocols must be followed. These standards ensure that lighting performance aligns with both biological requirements and regulatory guidelines.

.png)

Measurements begin with cattle-specific metrics such as CaPFD (Cattle Photon Flux Density), which must be evaluated using spectrally calibrated instruments to reflect how cattle actually perceive light. While lux can serve as a rough indicator, accurate conversion to CaPFD values is essential, often relying on conversion factors (e.g., a 4000K LED light with an XD factor of 70). In addition, compliance testing covers multiple areas: spectral accuracy, photon flux stability, flicker levels, IP rating validation, and corrosion resistance under farm conditions.

By adhering to these precise testing standards, farmers and facility managers can trust that their commercial dairy light fixtures not only meet technical specifications but also deliver consistent benefits to cattle health, welfare, and productivity.

Operational Benefits

The benefits of well-designed cattle chute lighting systems extend across productivity, energy savings, and animal welfare.

Milk Production Gains – Long-day lighting (16–18 hours) increases lactating cows’ milk yield by 5–16% and feed intake by 6%.

Energy Savings – LEDs with high CaQE (≥1.5 μmol/J) reduce energy costs while maintaining biological effectiveness.

Animal Welfare Improvements – Uniform, flicker-free lighting reduces stress, improves resting patterns, and supports reproductive health.

Together, these outcomes demonstrate that commercial dairy light fixtures are vital investments that pay back in both economic and biological performance.

Conclusion

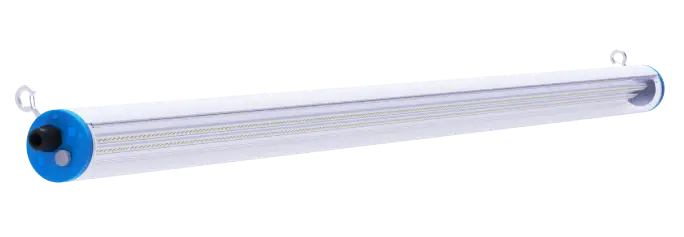

Choosing the right type of LED barn light is the final step in implementing an effective cattle lighting strategy. The design and build quality of the LED barn lights determine how well the system performs under challenging farm conditions.

For instance, models such as the T21 LED Barn Light are engineered specifically for agricultural use, offering wide beam angles for uniform coverage, IP69K protection for high-pressure washdown environments, and corrosion resistance to withstand ammonia and nitrates. These features make them ideal for barns, feeding troughs, and chute areas where durability and hygiene are critical. At the same time, their high energy efficiency and long service life ensure that they remain cost-effective over time.

Ultimately, the selection of robust and efficient cattle chute lights or commercial dairy light fixtures ensures long-term reliability, reduced maintenance, and sustained biological benefits for the herd. Investing in purpose-built LED solutions is therefore a strategic decision for any modern dairy or cattle operation.

_thumb.jpg)