IK Rating for LED Light Fixtures: The Ultimate Guide

Table of Contents

How is Impact Protection Rating Tested?

Breaking Down IK Ratings for LED Lighting

Why High IK Ratings are Critical for Your Facility?

IK Rating & IP Rating: The Dual Pillars of Durability

Which IK Rating Do You Need? (Selection Guide)

Examples and Applications of IK Ratings

Introduction

Imagine this scenario: A forklift in your warehouse accidentally clips a low-hanging light fixture, or a high-pressure water jet in a livestock shed knocks a lamp loose. In seconds, your facility faces shattered glass, safety hazards, and costly downtime.

This is where understanding what is IK rating becomes critical.

For facility managers in industrial, sports, and livestock sectors, lighting isn't just about brightness; it's about survival in tough environments. While Ingress Protection (IP) ratings handle water and dust, the IK rating in lighting defines how well a fixture can withstand physical impact.

Choosing the right rating isn't about always buying the most expensive, armored-tank specification. It's about finding the perfect balance between durability and cost-efficiency.

In this guide, we will break down the IK rating standard (IEC 62262) and help you select the ideal protection level—whether it's the robust IK08 standard or the extreme IK10—to ensure your operations never go dark.

What is an IK Rating?

The IK rating meaning is straightforward: it stands for "Impact Protection" (the K comes from "Kinetic" energy). It is an international numeric classification that indicates the degree of protection provided by electrical equipment enclosures against external mechanical impacts.

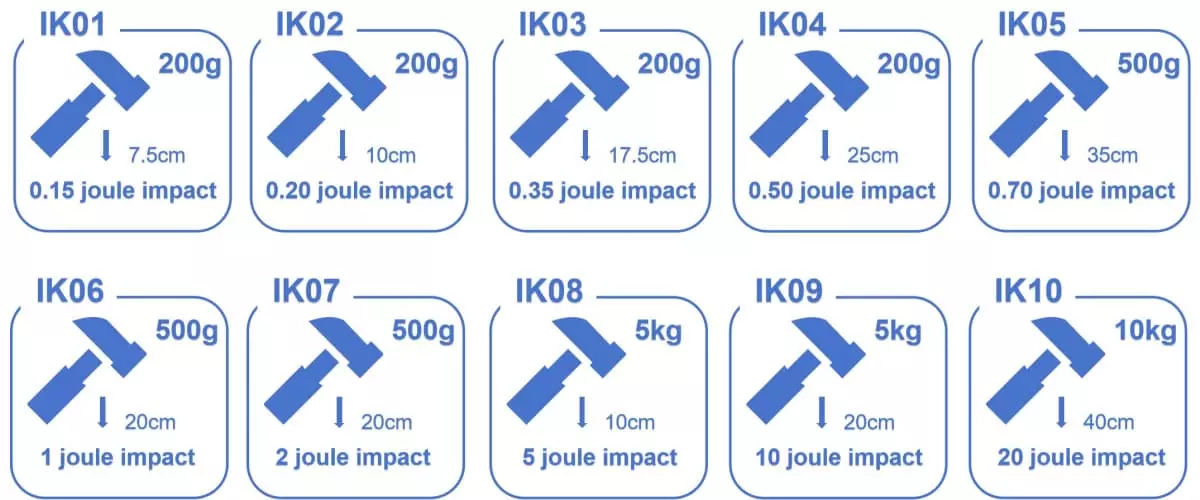

Defined by the standard IEC 62262, the scale ranges from IK00 (no protection) to IK10 (maximum protection).

For LED light fixtures, this number tells you exactly how much energy (measured in Joules) the fixture can absorb without breaking.

l Low Ratings (IK00-IK06): Typically found in standard residential or decorative lighting.

l High Ratings (IK07-IK10): Essential for industrial, sports, and agricultural applications where rough handling is expected.

The IK Rating Chart

When selecting fixtures, you don't need to guess. Use this IK rating chart to compare the impact energy against real-world scenarios.

IK Code | Impact Energy (Joules) | Equivalent Impact Scenario (Approximate) | Protection Level |

IK00 | 0 | No protection | None |

IK01 - IK05 | < 1 Joule | A gentle tap or light knock | Very Low |

IK06 | 1 Joule | A 500g object dropped from 20cm | Standard Livestock |

IK07 | 2 Joules | A 500g object dropped from 40cm | Low Risk Areas |

IK08 | 5 Joules | A 1.7kg hammer dropped from 30cm | Industrial Standard |

IK09 | 10 Joules | A 5kg object dropped from 20cm | High Risk |

IK10 | 20 Joules | A 5kg mass dropped from 40cm | Vandal Resistant |

Note: The IK impact rating increases exponentially. An IK08 fixture (5 Joules) is significantly stronger than an IK06 fixture (1 Joule), making it the preferred upgrade for modern facilities.

How is Impact Protection Rating Tested?

You might wonder, how is IK rating tested? It is not as simple as hitting a light with a baseball bat. To comply with the IK rating standard, manufacturers use a rigorous scientific method known as the Charpy Pendulum Test or a Vertical Free Fall Hammer test.

A picture of modern impact test machine.

Source: Wikipedia

The Testing Process:

Controlled Environment: The testing takes place under specific atmospheric conditions to ensure accuracy.

The Impact: A specified weight (the hammer) is dropped or swung from a precise height to hit the enclosure.

Strike Points: The fixture is hit five times on each exposed face to ensure there are no weak spots.

If the fixture maintains its integrity and safety after these impacts, it is awarded the corresponding IK rating. This ensures that when you see a specification like IK08 or IK10, it is a certified promise of durability, not just marketing fluff.

Breaking Down IK Ratings for LED Lighting

Not every facility needs a light fixture built like a tank. Understanding the nuances of IK rating for lighting helps you avoid overspending on unnecessary specs while ensuring you don't under-spec for safety.

Here is how the hierarchy works in the real world:

l IK01 – IK06 (Low Impact):

These ratings are generally restricted to indoor decorative lights or recessed downlights.

Note: While many standard livestock lights on the market are still rated IK06 (protecting against 1 Joule), this is often insufficient for modern farming environments where equipment or animals can easily breach the housing.

l IK07 (2 Joules):

Common in offices, schools, and hallways. These fixtures can withstand accidental bumps, but they are not designed to resist deliberate force or heavy industrial accidents.

l IK08 (5 Joules – The Industry Standard):

This is the "sweet spot" for most professional applications. An IK08 rating means the fixture can withstand the impact of a 1.7kg hammer dropped from 30cm.

For the majority of industrial warehouses, general sports courts, and well-managed livestock facilities, IK08 offers excellent protection. It is robust enough to survive basketball impacts or accidental tool drops, making it the most cost-effective choice for durability.

l IK09 (10 Joules):

A step up for high-risk public areas, such as subway stations or unsupervised campuses, where minor vandalism is a concern.

l IK10 (20 Joules – The Gold Standard):

The highest IK 10 impact rating is often labeled "Vandal Resistant." Capable of absorbing 20 Joules (a 5kg mass dropped from 40cm), this is reserved for the most extreme environments—such as prisons, heavy industrial zones with mobile cranes, or professional stadiums where ball velocity is maximum.

Why High IK Ratings are Critical for Your Facility?

Ignoring IK impact ratings is a gamble with safety and ROI. A cracked lens doesn't just look bad; it breaks the waterproof seal, leading to electrical failure. Here is why specific sectors demand high durability:

In Livestock Farming (Pigs, Cows, Poultry)

Animals are unpredictable. A startled sow or a cow can kick a low-hanging fixture with surprising force. While standard IK06 lights might shatter, an IK08 or IK10 fixture remains intact, preventing glass from contaminating feed.

The IP69K Factor:

In farming, impact resistance is only half the battle. Because barns require frequent sanitation, you must look beyond just IK. You need the ultimate combination: IK08/IK10 + IP69K.

While IK ratings handle the physical hits, IP69K ensures the fixture can withstand high-pressure (100 bar), high-temperature (80°C) steam cleaning. Ceramiclite recommends this dual protection to ensure the light survives both the animal's kick and the pressure washer.

In Sports Stadiums

In tennis, cricket, or hockey, projectiles travel at high speeds. A shattered light over a playing field is a major liability that stops the game immediately.

Ø Recreational Courts: IK08 is typically sufficient to withstand standard ball impacts.

Ø Professional Arenas: An IK 10 rating provides the maximum insurance against high-velocity direct hits.

In Warehouses & Industry

Industrial spaces are full of vibration and movement. Forklift masts, moving robotic arms, or falling inventory can clip lighting fixtures. High IK ratings ensure that a minor accident doesn't turn into a maintenance shutdown.

IK Rating & IP Rating: The Dual Pillars of Durability

When reading specification sheets, you will often see IP and IK rating listed side-by-side. It is important not to view these as "one vs. the other," but rather as partners in protection.

Ø IP (Ingress Protection): Acts as the "Raincoat." It stops water, dust, and steam from entering the fixture (e.g., IP66, IP67, IP69K).

Ø IK (Impact Protection): Acts as the "Shield." It stops physical blows from breaking the casing (e.g., IK08, IK10).

The Critical Link:

If a fixture has a high IP rating (waterproof) but a low IK rating (brittle), a single physical impact will crack the housing. Once cracked, the IP rating becomes useless—water enters, and the light fails.

For any outdoor, industrial, or agricultural application, "dual certification" is mandatory. You should aim for a baseline of IP66 combined with IK08 to ensure true longevity.

Which IK Rating Do You Need? (Selection Guide)

Still asking "what are IK ratings best suited for my project?" Use this simple checklist to match your environment with the right spec:

Low Traffic / Indoor Offices:

Recommendation: IK07. Sufficient for rare, accidental contact.

General Industry / Recreational Sports / Standard Agriculture:

Recommendation: IK08.

Why? This is the rational choice. It handles significantly more force than IK06 and covers 90% of physical risks without the premium cost of extreme fortification.

High-Risk Zones / Professional Stadiums / Heavy Machinery Areas:

Recommendation: IK10.

Why? Mandatory where deliberate damage, high-speed projectiles, or heavy collisions are daily risks.

Examples and Applications of IK Ratings

Theory is useful, but seeing how IK rating lighting performs in the field helps drive the decision home. Here is how Ceramiclite fixtures solve specific industry challenges:

Sports Lighting (Stadiums & Courts)

l Scenario: A tennis ball traveling at 120 km/h strikes a floodlight directly.

l The Ceramiclite Solution: Our Sports lights come equipped with IP66 weather protection and options for IK08 or IK10 impact resistance.

l Result: Whether it is a training court (IK08) or a professional arena (IK10), the fixture absorbs the shock without cracking. This means facility managers don't need to rent cherry pickers to replace broken lights after a match, ensuring continuous play.

(Suggested Image: A Ceramiclite High Bay installed high above an indoor tennis court.)

Livestock & Agriculture

l Scenario: A pig farm requires daily high-pressure sanitation, and animals occasionally bump into low-level equipment.

l The Ceramiclite Solution: We offer specialized livestock lighting with IP67/IP69K ratings to withstand ammonia corrosion and steam cleaning.

l Result: While we provide standard IK06 models, we highly recommend our IK08 upgraded fixtures for breeding areas. This combination of IK08 strength + IP69K sealing ensures the light survives both the animal’s kick and the pressure washer, maximizing the lifespan of your barn lighting.

(Suggested Image: A close-up of a Ceramiclite tubular light being washed down in a livestock shed.)

Industrial Warehousing

l Scenario: High vibrations from overhead cranes and the risk of accidental forklift impacts.

l The Ceramiclite Solution: Our Industrial UFO High Bays feature a robust IK08 rating paired with IP67 waterproofing.

l Result: The IK08 rating effectively handles mechanical vibrations and accidental knocks common in logistics centers, making it the reliable, cost-effective standard for industrial facilities.

(Suggested Image: A wide shot of a logistics warehouse illuminated by Ceramiclite LED High Bays.)

Conclusion

Choosing the right light fixture is about risk management. Saving a few dollars upfront on a low-rated fixture often leads to significantly higher costs later—through frequent replacements, maintenance labor, and operational downtime.

Whether you need the industrial reliability of IK08 or the extreme defense of IK10, ensuring your specs match your environment is the key to long-term savings.

Ready to upgrade to durable lighting? Explore our range of IK08 and IK10 certified LED fixtures at Ceramiclite today to find the perfect match for your facility.

_thumb.jpg)