産業照明基準 OSHA コンプライアンスガイド

目次

産業用照明における OSHA コンプライアンスを確保するにはどうすればよいでしょうか?

OSHA 照明基準が産業環境で重要な理由

産業現場において、適切な照明は単なる利便性ではなく、法的および安全上の要件です。OSHA (労働安全衛生局)の産業照明基準 は、工場、倉庫、生産現場における照明の明るさ、均一性、安全性の基準を定めています。

これらの規格は、労働安全衛生局 (OSHA)によって発行され 、作業者を事故から保護し、目の疲れを軽減し、すべての作業が正確かつ確実に実行されるように設計されています。

照明レベルがOSHAの最低要件を下回ると、リスクは増大します。滑り、距離の見落とし、操作ミスなどが発生しやすくなります。視界不良は生産性の低下、疲労の増加、さらには高額なダウンタイムや法的罰則につながる可能性があります。

多くの施設管理者は、照明システムの規制遵守とコストおよび実用性のバランスを取ることが必ずしも容易ではないという難しさを身をもって経験しています。古い蛍光灯やメタルハライドランプはまだ「使える」かもしれませんが、時間の経過とともに明るさが落ち、重要な作業エリアが照度不足に陥ります。たとえ照明が十分に明るく見えても、不均一な配光やグレアによって作業員の視界が遮られ、疲労やミスが増える可能性があります。

忙しい産業環境では、こうした小さな照明の問題は、安全上の懸念が生じたり、OSHA の検査のきっかけになったりするまで、気付かれないことがよくあります。

一般産業向けの OSHA 照明基準を理解して適用すると、 組立ラインから保管通路まで、あらゆる作業スペースが安全性とパフォーマンスの両方の期待を満たすことが保証されます。

OSHAの照明要件の説明

OSHA の照明規則は一見すると技術的に見えますが、その目標はシンプルです。すべての職場を安全かつ明瞭に見渡せるようにすることです。

OSHA照明基準は 、いくつかの主要なセクションに分かれています。

OSHA 1910 は、工場、倉庫、作業場を含む一般産業 を対象としています。

OSHA 1915 は造船所および海洋事業 に適用されます。

OSHA 1926 は建設現場および一時作業区域 を規制します。

これらの規格の中でも、OSHA 1910.37は 最も頻繁に参照されるセクションの一つです。この規格は、停電時や緊急時の安全な避難を確保するための避難経路と非常通路の照明要件を規定しています。OSHAはまた、米国規格協会(ANSI)と照明工学協会(IES)が共同で策定したガイドラインであるANSI/IES RP-7も頻繁に参照しており、これは様々な産業作業における適切な照明レベルを推奨しています。

照明性能はフートカンデラ(fc)で測定されます。1フートカンデラは、1フィート離れた1本のろうそくの光量に相当します。海外の読者の方のために説明すると、1fcは約10.76ルクスです。OSHA(労働安全衛生局)は、様々な作業区域の最低照度レベルを設定する際に、フートカンデラを測定単位として使用しています。

適合性を確認するため、検査員は作業者の目の高さまたは作業レベルに設置した照度計を用いて照度を測定します 。測定は作業エリア内の複数の地点で行われ、平均化することで、均一かつ適切な照明を確保します。明るい箇所だけでなく、作業スペース全体にわたって均一で信頼性の高い照明が確保されていることが重要です。

OSHA の照明基準と測定方法の詳細な概要については、公式の OSHA 照明要件ページをご覧ください。

作業エリアごとの最小照度レベル

作業区域ごとに照明のニーズは異なります。例えば、荷積み場は実験室と同じ明るさを必要としません。そのため、OSHAの倉庫 やその他の施設の照明基準では、安全性と視認性の両方を維持するための最低照度が定められています 。

これらの値はフートカンデラ(fc)で測定され、 10.76 を掛けることでルクスに変換できます。

以下は、産業環境で推奨される一般的な照明レベルです。

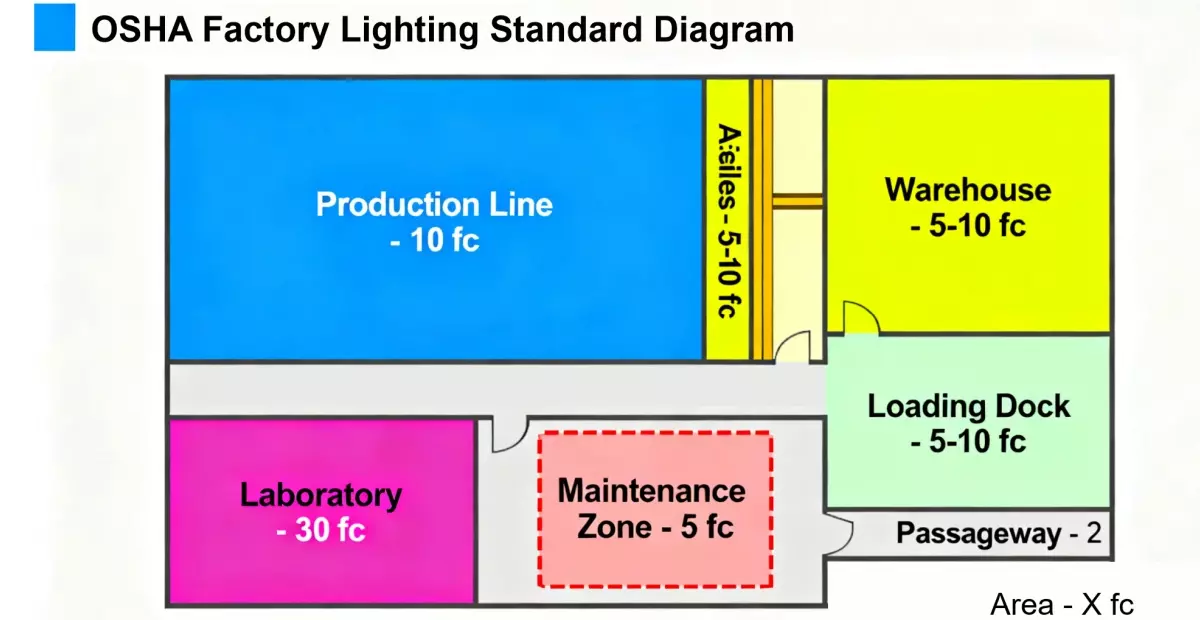

工場および生産ライン: 10 fc (≈108 ルクス) – 一般的な組み立ておよび検査には十分です。

倉庫、荷積み場、通路: 5~10 fc(≈54~108 ルクス)– 移動や資材の取り扱いには十分です。

研究室および救急ステーション: 30 fc (≈323 ルクス) - 精密作業や安全チェックのためのクリアな視界を確保します。

階段と通路: 2 fc (≈22 ルクス) – つまずきを防ぎ、安全な移動を維持します。

メンテナンスゾーン、トンネル、地下エリア: 5 fc (≈54 ルクス) - 修理作業に十分な照明を提供します。

OSHA産業照明基準図

産業用照明暗すぎると障害 物が隠れてしまい、事故のリスクが高まります。一方、明るすぎると まぶしさや目の疲れ、疲労の原因となります。最適な方法は、安全性と正確性を確保できる明るさと、快適性を確保できる柔らかさのバランスの取れた照明です。

均一で適切に分散された照明は、作業者が自信を持って作業を遂行し、エラーを減らすのに役立ちます。これは、研究室や倉庫環境における OSHA 照明基準に準拠し続けるために重要な要素 です。

OSHAの照明器具およびカバーの要件

OSHAの照明カバー要件は、明るさのレベルだけでなく、 照明器具の安全性、つまり照明器具自体が危険にならないことに重点を置いています。産業照明基準によれば、職場のすべての照明器具は、適切に遮蔽、設置され、衝撃や破損から保護されなければなりません。

すべての照明器具には、電球が破損した場合にガラスや破片が落下するのを防ぐため、保護カバー または飛散防止シールドを取り付ける必要があります。倉庫、給油所、荷積み場 など、機械やフォークリフトが稼働する場所では、この保護が特に重要です。

器具は作業面から少なくとも7フィート(約2メートル)の高さに設置する必要があります。それより低い高さに設置する必要がある場合は、OSHA(労働安全衛生局)の規定により、偶発的な接触を防ぐためのガードまたは保護ケージの 設置が義務付けられています。器具には露出した通電部品 や指が届くほどの大きな開口部があってはなりません。また、振動による緩みを防ぐため、すべての照明器具はしっかりと固定する必要があります 。

これらの要件を満たすことで、コンプライアンスの問題を回避できるだけでなく、より安全で長持ちする照明システムが確保され、要求の厳しい産業環境における作業員、設備、在庫が保護されます。

一般的なコンプライアンスギャップとOSHA違反

優れた照明システムを備えた施設であっても、実際の運用においてはOSHAの産業照明基準を満たしていないことがよくあります 。以下に挙げる一般的な違反は、単なる技術的な見落としではなく、事故、罰金、そして責任につながる現実的なリスクです。

1. 「ハイシェルフの盲点」

背の高いラックが設置された倉庫では、光の減衰や照明器具の配置の悪さにより、上層階に必要な照度の一部しか得られないことがよくあります。このような薄暗い場所で商品を取り出している作業員は、距離の判断を誤ったり、障害物を見落としたりする可能性があり、落下物やフォークリフトとの衝突のリスクが高まります。

OSHAは 、地上作業だけでなく、すべての作業レベルに適切な照明を義務付けています。規制遵守のためには、ラックの高さを変えて定期的に照度テストを行うことが不可欠です。

2. 「メンテナンスの罠」

機器や施設のメンテナンス作業では、作業員が手持ちランプ、延長コード、ポータブル投光器など、臨時の照明を設置することがよくあります。しかし、これらの多くは防爆または防水性能を満たしておらず、特に埃、湿気、揮発性化学物質が存在する環境では問題となります。

これにより、ショート、感電、さらには火災といった隠れた危険が生じます。

OSHA 1926.405(a)(2)(ii)(J)では、すべての臨時照明は恒久的な設備と同じ安全基準を満たす必要があると規定されています。

3. 「グレアハザード」

照明不足は問題ですが、明るすぎる照明 や遮蔽されていない照明器具 も同様に危険です。作業員がフォークリフトを操作したり、光沢のある金属面を扱ったりする場所では、グレアによって一時的な失明を引き起こす可能性があります。一瞬の視力喪失は、深刻な怪我につながる可能性があります。

OSHA は、 視覚疲労やグレア関連の事故を防ぐために、拡散照明または遮蔽照明を使用し、輝度の均一性を確保することを推奨しています。

4. 色再現性とコントラストを無視する

見落とされがちなもう一つの問題は、演色性の低いランプの使用です。製造現場や検査現場では、演色評価数(CRI)の低い照明では配線の色、ラベル、表面の欠陥の識別が難しく、誤接続や製品品質の問題に直接つながる可能性があります。

OSHA 準拠の照明は、 色と材質を安全に認識できるように、ほとんどの産業環境で最低 70の CRIを維持する必要があります。

5. 定期的な照明監査の欠如

多くの施設では、設置後に照明レベルを再確認していません。時間の経過とともに、ほこりの蓄積、レンズの黄ばみ、LEDルーメンの低下により、 明るさが20~30%低下する可能性があります。事故が発生した場合、事後調査で照明システムがOSHAの最低ルクス要件を下回っていたことが判明することがよくあります。

コンプライアンスを維持し、罰金を回避するには、6 ~ 12 か月ごとに定期的に監査を実施し、結果を文書化することが不可欠です。

まとめると、 OSHA違反は、薄暗い隅、眩しい場所、メンテナンスが行き届いていない場所など、小さなことから始まることがよくありますが、最終的には高額な損害につながる可能性があります。積極的な点検、適切な照明設計、そしてOSHAの照明基準の遵守は、職場の安全と法令遵守の両方を実現します。

産業用照明における OSHA コンプライアンスを確保するにはどうすればよいでしょうか?

産業用照明基準を満たすことは 、単にチェックリストにチェックを入れるだけの作業ではありません。従業員の安全を確保し、罰金を回避し、円滑な操業を維持するための重要な要素です。最適なアプローチは、コンプライアンスをシンプルで繰り返し可能な4つのステップにまとめることです。

1. 監査 – 現状を測る

まず、ルクスメーターを用いて照明の徹底的な監査を実施します。生産フロア、倉庫、荷積みエリアを、一日の様々な時間帯に歩き回ります。暗い場所、グレアの出ている場所、明るさのムラなどを特定します。これらの測定値を記録し、OSHA(労働安全衛生局)推奨のルクスレベルと比較します。

2. 計画 – スマートアップグレードマップを作成する

監査結果に基づき、照明改善計画を策定します。フォークリフトレーン、階段、組立エリアなど、視認性が安全性に直接影響する高リスクゾーンを優先します。レイアウト変更、照明器具の配置、エネルギー効率目標などを検討します。

3. 実装 – 認定LED照明を設置する

OSHA準拠のLED照明器具をお選びください。UL 、DLC、CEなど、 適切な認証を取得しています。過酷な環境や危険な場所での使用には、適切なIP規格 と防爆規格をご確認ください。

ハイベイとエネルギー効率に優れた産業用 LED 照明システムは 、均一な明るさ、長寿命、最大 70% のエネルギー節約を実現する理想的な選択肢です。

4. 維持 – 長期にわたって基準を維持する

設置後もコンプライアンスは維持されます。6ヶ月ごとに照度チェックを実施 し、器具を定期的に清掃してください。わずかなほこりでも明るさが20%低下する可能性があります。停電時の対応として、バックアップ電源付きの非常照明を設置し 、継続的な安全確保に努めましょう。

このシンプルな監査、計画、実装、維持のループに従うことで 、施設はOSHAに完全に準拠しながら、産業用LED照明 の効率、寿命、コスト削減のメリットを享受できます。。

OSHA照明基準を満たすことの利点

OSHA 照明基準に準拠することは、 罰金を回避することにとどまらず、従業員と長期的な生産性への投資となります。

より安全で集中した作業

適切な照明は、作業員の視界を良くし、危険を回避し、疲労を軽減するのに役立ちます。隅々まで明るく照らされていれば、滑ったり、つまずいたり、機器の取り扱いを誤ったりするリスクが大幅に低減します。

効率と士気の向上

良好な視界は生産ラインの円滑な稼働を維持し、組み立てや検査といった精密作業をサポートします。明るい環境では、従業員はより自信を持ち、仕事に熱心に取り組めます。

エネルギーとメンテナンスコストの削減

LED 照明に切り替えると、エネルギー消費量を50~70% 削減できるほか、器具の寿命が延び、メンテナンスによるダウンタイムも短縮されるため、安全性と持続可能性の両方のメリットが得られます。

より強力な評判とコンプライアンス

OSHA基準を満たす施設は、専門性と信頼性を証明します。コンプライアンスは、従業員の安全を守るだけでなく、顧客監査や安全審査においてブランド力を強化することにもつながります。

つまり、適合照明への投資は、持続可能なパフォーマンスと長期的な成功への投資を意味します。

結論

産業照明基準の理解と遵守OSHAは 、規制遵守だけでなく、より安全でスマート、そして効率的な職場環境の構築にも取り組んでいます。適切な照明は、労働者の安全を確保し、視認性を高め、高額な事故を防ぐのに役立ちます。

最新のLED照明システムにより、OSHA(欧州安全衛生局)の規制遵守はかつてないほど容易になりました。LEDは、安定した明るさ、低いエネルギーコスト、最小限のメンテナンスで、あらゆるエリアで必要な照度レベルを確実に満たします。

信頼性の高い OSHA 準拠の照明に投資し、安全性と生産性に優れた職場を構築しましょう。

CeramicLiteのプロフェッショナル産業用照明ソリューションをご覧ください今日。

_thumb.jpg)