Lux vs Lumens vs Candela: The Definitive Guide for Lighting

Table of Contents

Introduction: The "High Lumens" Trap

Lux vs Lumens vs Candela: Key Differences Table

Which Metric Matters Most for Your Project?

Stop Guessing. Start Engineering.

Introduction: The "High Lumens" Trap

Have you ever bought an LED light labeled with high "Lumens," only to install it and find the area still looks dim? You are not alone. This is the most common mistake in lighting upgrades.

Many buyers believe that Lumens is the only metric for brightness. But in reality, lighting is three-dimensional. Whether you are lighting a backyard, a warehouse, or a stadium, relying solely on Lumens can lead to poor visibility and wasted energy.

To truly control your lighting environment, you need to understand the "Triangle of Light": Lux, Lumens, and Candela.

In this guide, Ceramiclite’s experts break down these three confusing terms into simple concepts. We will explain how they interact, why they matter, and how to stop guessing and start calculating the exact light you need.

What is Lumens?

When you look at a spec sheet, Lumens (lm) is often the first number that jumps out. Technically known as Luminous Flux, it represents the total quantity of visible light energy emitted by a source in all directions. Think of it as the "horsepower" of your lighting engine—it tells you the raw potential of the fixture.

However, in the commercial lighting industry, Lumens can be the most misleading metric if viewed in isolation. A high lumen rating simply indicates that the LED chips are generating a lot of light, but it doesn't account for where that light goes.

This leads to a common frustration for buyers: the difference between Source Lumens and Delivered Lumens. Many manufacturers market the theoretical output of the LED chip (Source Lumens), ignoring the light lost inside the fixture's lens or heat sink. For a warehouse manager or industrial buyer, paying for 30,000 lumens is pointless if an inefficient optical design only delivers 20,000 lumens out of the fixture. High lumen output with low efficacy (lumens per watt) is just wasted electricity disguised as brightness.

What is Lux?

While Lumens measure what leaves the fixture, Lux (lx) measures what actually arrives at your target. This is the metric of Illuminance—the intensity of light hitting a specific surface area. In the metric system, one Lux equals one Lumen spread over one square meter.

For professionals, Lux is not just a number; it is the benchmark for compliance and operational success. It translates abstract light data into tangible user experiences. The requirements vary drastically depending on the precision of the task at hand.

Take livestock farming as a prime example. In a poultry house, the lighting design is delicate; you might aim for a uniform 20 to 30 Lux on the floor. This level is scientifically calibrated to encourage feeding without causing aggression or stress among the birds. Conversely, in an industrial precision workshop or an electronics assembly line, the standard jumps dramatically to 750 Lux or higher. Here, the high illuminance is critical for safety and quality control, ensuring that workers can see microscopic details without eye strain. Ultimately, you buy Lumens, but you are paying for Lux.

What is Candela?

In the realm of specialized lighting—particularly for Sports and High-Mast applications—Candela (cd) is arguably the most critical yet overlooked parameter. It measures Luminous Intensity, or how "dense" the light is in a specific direction.

If Lumens represents the size of the water tank, Candela is the pressure at the nozzle. It determines the throw and penetration of the light beam. This is where general-purpose floodlights fail against professional stadium lights. A fixture might have massive lumen output, but if it lacks high candela (intensity), the light will scatter into the atmosphere before it ever reaches the ground.

This distinction is vital for large-scale venues. Consider a Cricket Stadium where lights are mounted on poles 30 to 40 meters high. The light must travel a significant distance and still hit the pitch with enough intensity for high-speed cameras and players. A fixture with high Lumens but low Candela will light up the night sky (creating light pollution), but leave the center of the pitch dark. To push light from the top of a mast down to the wicket, you need a narrow beam angle and high Candela values. In short, Candela is the force that delivers the light exactly where you need it, over long distances.

Lux vs Lumens vs Candela: Key Differences Table

To help you make the right decision for your facility, we have summarized the critical distinctions between these three metrics. Note how the "Primary Focus" shifts depending on your role in the project.

Metric | Unit | What it Measures | The Simple Question It Answers | Primary Application Focus |

Lumens | lm | Total Output (Luminous Flux) | "How much total light is this bulb producing?" | Energy Efficiency (Comparing lm/W efficacy for industrial retrofits). |

Lux | lx | Result on Surface (Illuminance) | "How bright will the floor/desk actually be?" | Compliance & Safety (Meeting standards for workspace or animal welfare). |

Candela | cd | Intensity in Direction (Luminous Intensity) | "How strong is the beam? How far can it reach?" | Optical Design (Crucial for stadium lighting & high-mast poles). |

The Relationship

Understanding these lighting terms individually is good, but understanding how they interact is what separates a lighting professional from a novice. The easiest way to visualize this relationship is to imagine a garden water hose.

Lumens is the Water Flow: Imagine you turn on the tap. The total amount of water flowing out of the hose every second represents Lumens. It doesn't matter if you spray it wide or narrow; the total volume of water (light energy) remains the same.

Lumens is the Water Flow: Imagine you turn on the tap. The total amount of water flowing out of the hose every second represents Lumens. It doesn't matter if you spray it wide or narrow; the total volume of water (light energy) remains the same.

Candela is the Nozzle Pressure: Now, imagine you twist the nozzle to narrow the stream. The water shoots further and harder. You haven't added more water, but you have concentrated it into a specific direction. This increased intensity is Candela.

Lux is the Wet Surface: Finally, look at the ground where the water hits. The wetness of the grass represents Lux.

² If you use a wide spray (Low Candela), the water covers a large area, but the ground is only slightly damp (Low Lux).

² If you use a focused jet (High Candela), you cover a smaller area, but that spot gets soaked instantly (High Lux).

The Takeaway: In lighting design, you cannot just ask for "more Lux" without considering the beam angle (Candela) and total output (Lumens). They are inextricably linked.

Reference:

https://en.wikipedia.org/wiki/Lux

https://en.wikipedia.org/wiki/Lumen_(unit)

https://en.wikipedia.org/wiki/Candela

https://www.britannica.com/science/candela

How to Convert Lux to Lumens?

In many projects, you start with a Lux requirement—for example, a warehouse manager knows they need 200 Lux on the floor—and you need to work backward to figure out how many Lumens to buy.

The basic relationship is defined by the formula:

Lumens=Lux×Area (square meters)Lumens=Lux×Area (square meters)

Note: If you are working in square feet (foot-candles), the logic is similar, but the units differ.

Quick Calculator

Use our tool below to get a baseline estimate for your project needs.

Lux to Lumens Calculator

Result: 0 Lumens

Why "Calculated Lumens" is rarely "Required Lumens"

While the calculator above gives you a mathematical baseline, please proceed with caution. The formula Lumens=Lux×Area assumes a perfect world where 100% of the light from the fixture hits the floor. In the real world, this never happens.

As lighting engineers at Ceramiclite, we always factor in two critical variables that simple calculators miss:

1. Light Loss Factor (LLF): Over time, LED output degrades slightly, and dirt accumulates on lenses. We design with a depreciation factor (usually 0.8 or 0.9) to ensure your facility stays bright even after 5 years.

2. Coefficient of Utilization (Cu): Not all light leaves the fixture in the right direction. Some is absorbed by walls or lost in the ceiling (especially in high-bay applications).

Pro Tip: The result you see above is the minimum theoretical lumen output. For a robust industrial or sports lighting design, you typically need to aim for 30% to 50% higher lumen output to account for these real-world losses.

Which Metric Matters Most for Your Project?

Context is king. A high-lumen fixture that is perfect for a warehouse might be a disaster for a chicken coop. Now that you understand the definitions, here is how professional lighting designers prioritize these metrics across Ceramiclite’s three core sectors.

1. Sports Lighting (Cricket Grounds, Football Stadiums)

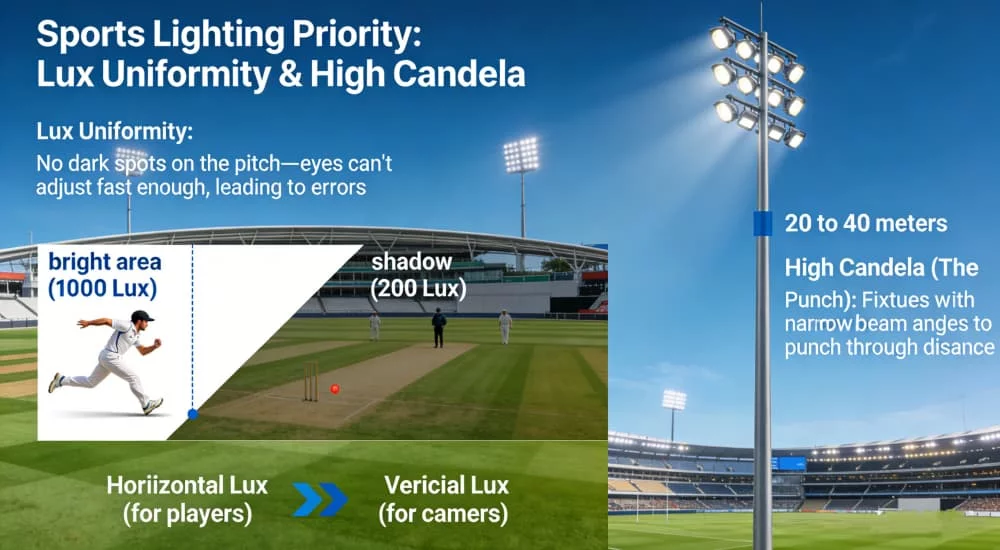

The Priority: Lux Uniformity & High Candela

In sports lighting, "bright enough" is not enough. The light must be consistent.

l Why Lux Uniformity: You cannot have dark spots on the pitch. If the bowler runs from a bright area (1000 Lux) into a shadow (200 Lux), their eyes cannot adjust fast enough, leading to errors. We focus on Horizontal Lux for the players and Vertical Lux for the cameras.

l Why Candela (The Punch): Because stadium poles are often 20 to 40 meters high, you need fixtures with exceptionally high Candela (narrow beam angles) to punch through the distance.

l The Ceramiclite Approach: We prioritize fixtures with advanced optics that deliver high intensity (Candela) to the field center while minimizing spill light to the neighbors.

2. Livestock Lighting (Poultry Farms, Dairy Barns)

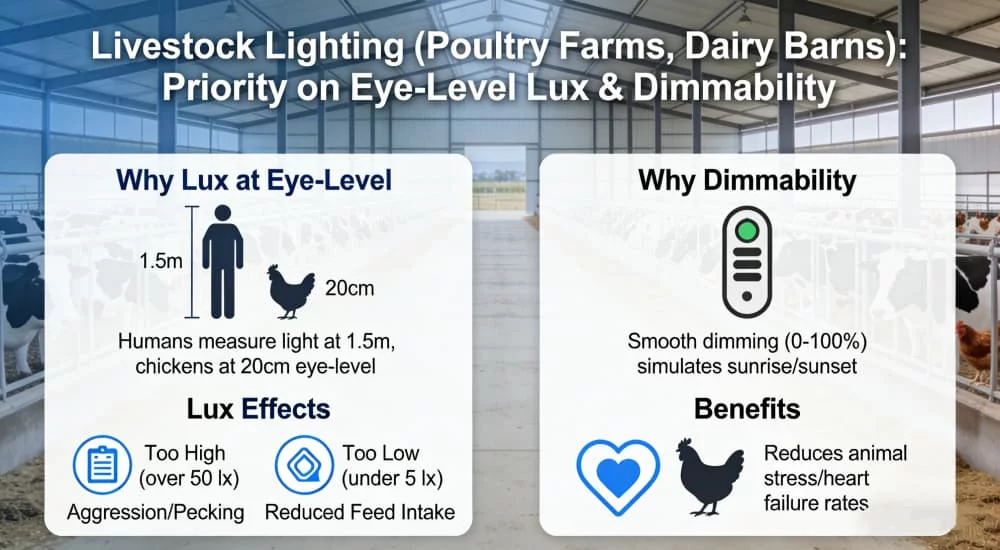

The Priority: Lux at Eye-Level & Dimmability

For animals, light is a biological signal, not just visibility.

l Why Lux at Eye-Level: A human standing in a barn might measure light at 1.5 meters high, but a chicken lives at 20cm. We calculate Lux at the animal's eye level. Too high Lux (over 50 lx) can cause aggression and pecking; too low (under 5 lx) reduces feed intake.

l Why Dimmability: You don't need static brightness; you need control. Smooth dimming (0-100%) is required to simulate sunrise and sunset, reducing animal stress and heart failure rates.

l The Ceramiclite Approach: We focus on spectrum-specific Lux (optimized for animal vision) rather than just raw Lumens, ensuring better growth rates and welfare.

3. Industrial Lighting (Warehouses, Manufacturing)

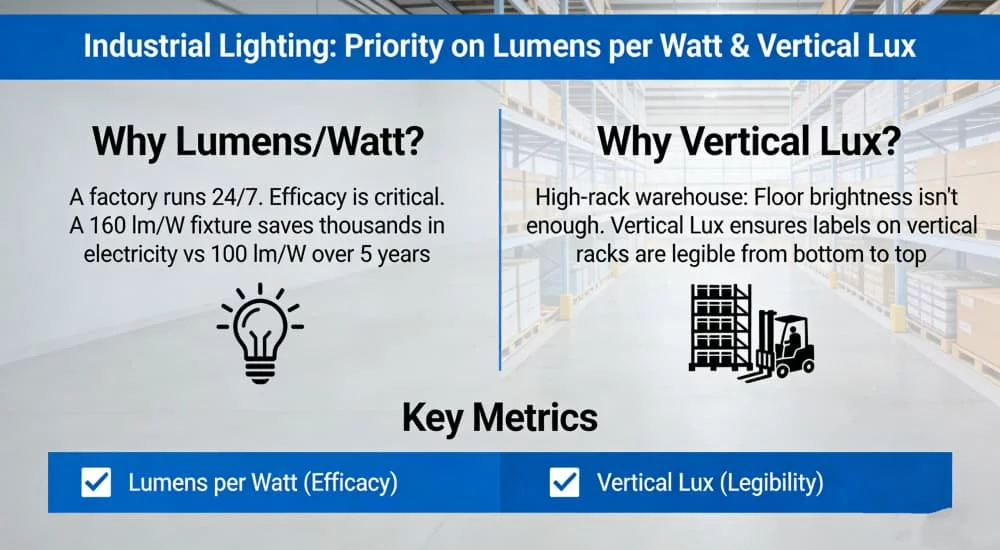

The Priority: Lumens per Watt (Efficiency) & Vertical Lux

In the industrial sector, lighting is an operational cost and a safety factor.

l Why Lumens/Watt: A factory runs 24/7. The most critical metric here is Efficacy. A fixture delivering 160 lumens per watt will save thousands of dollars in electricity compared to a standard 100 lm/W fixture over five years.

l Why Vertical Lux: In a high-rack warehouse, it doesn't matter if the floor is bright if the forklift driver cannot read the label on the shelf. We design for Vertical Lux to ensure labels on vertical racks are legible from bottom to top.

l The Ceramiclite Approach: We balance high-efficiency output with low-glare optical lenses to prevent driver fatigue.

Stop Guessing. Start Engineering.

Lighting calculations are complex. A simple math error between Lux and Lumens can result in a dark stadium, stressed livestock, or a dangerous workplace.

Why risk your investment on a theoretical calculator?

At Ceramiclite, we don't just sell lights; we provide certainty. Our engineering team uses professional DIALux simulation software to build a 3D model of your specific facility. We calculate the exact reflection, beam angles, and light loss factors to prove the results before you buy a single fixture.

Ready to see your project in the best light?

_thumb.jpg)