Pole Barn Lighting Guide: Layouts, Lumens & Solutions

Table of Contents

Define Your Purpose (What is the Barn For?)

Choosing the Right Fixture Type

Understanding the Specs: CCT, CRI, and Photoperiod

Why Upgrade to LED Pole Barn Lights?

The Hidden Weakness of Standard LEDs

Ceramiclite Solution: FTC Technology & Graphene Innovation

How to Calculate Pole Barn Lighting Precisely?

Introduction

A pole barn is one of the most versatile buildings on a property. You might use it for cold storage, a machine shop, or to house livestock.

While the outside of the building looks the same, what you do inside dictates the lighting you need. One type of light does not fit all.

If you install a standard shop light in a dairy barn, the ammonia will corrode it within months. If you use a dim agricultural bulb in a workshop, you won’t be able to see well enough to work safely.

Choosing the right pole barn lighting comes down to three things: what you are doing, how high your ceiling is, and how durable the fixture needs to be. This guide covers exactly what you need for every application.

Define Your Purpose (What is the Barn For?)

Before buying fixtures, identify the main use of your building. Lighting requirements change drastically depending on the work being done.

1. Warehousing & Equipment Storage

If you are just parking tractors or storing hay, you don't need expensive, high-intensity lights.

The Goal: Basic visibility.

What You Need: Enough light to navigate safely and find tools. Instant-on LEDs are best for cold winters so you aren't waiting for lights to warm up.

2. Workshops & Garages

If you are repairing engines, welding, or doing woodwork, you need bright, clean light.

The Goal: See details clearly and work safely.

What You Need: High brightness (Lumens) and a cool white color (5000K). You also need a high CRI (Color Rendering Index) to see true colors—essential when reading wiring diagrams or matching paint.

3. Horse Barns

Horses are sensitive to flickering lights and harsh shadows.

The Goal: Safety for the animal and the handler.

What You Need: Flicker-free drivers are a must to keep animals calm. Good color rendering helps you spot health issues on the animal’s coat or hooves.

4. Livestock Farming (Poultry, Dairy, Swine)

This is the most demanding environment. Standard lights often fail here.

The Goal: Durability and production.

What You Need: You face dust, moisture, and corrosive gases like ammonia. You need sealed, corrosion-resistant fixtures. You also need dimming capabilities to control light cycles (photoperiods), which directly impacts milk yield and egg production.

Choosing the Right Fixture Type

Once you know the purpose of your pole barn, you need to pick the right shape and style of light. Ceiling height is usually the deciding factor.

Here is a breakdown of the three most common pole barn lighting types and the features you should look for.

1. UFO High Bay Lights

These are round, heavy-duty fixtures named for their saucer-like shape. They are the standard for industrial and large agricultural spaces.

These are round, heavy-duty fixtures named for their saucer-like shape. They are the standard for industrial and large agricultural spaces.

ü Best For: High Ceilings (15 ft and higher).

ü How They Work: UFO High Bays pack a lot of power into a small body. They use a lens to focus light downward, punching through the distance from a high truss to the floor.

ü Why You Need Them: If you have a large machine shed or an open-stall barn, you need raw power. A few of these can light up a massive space. They are also usually built tough (IP65+ waterproof ratings).

ü Product Recommendation: The UFO HB01 Series. Unlike standard aluminum lights, these use FTC technology to resist corrosion, making them perfect for wash-down bays.

2. Linear / Tube Lights

These are long, rectangular fixtures, similar to the old fluorescent shop lights but much more durable.

These are long, rectangular fixtures, similar to the old fluorescent shop lights but much more durable.

ü Best For: Low to Medium Ceilings (8 ft to 14 ft) or Long Aisles.

ü How They Work: Instead of a focused beam, linear lights have a wide angle (often 120 degrees or more). This spreads the light out horizontally.

ü Why You Need Them: If your ceiling is low, a High Bay light will be too intense in one spot and leave the rest dark. Linear lights eliminate shadows. They are ideal for over workbenches, in milking parlors, or down the center of an aisle.

ü Product Recommendation: The LED Barn Light T5. These are linkable (you can plug one into the next) and fully waterproof, so you can clean them easily.

3. LED Bulbs (Retrofit)

These look like standard light bulbs but are engineered for commercial use.

These look like standard light bulbs but are engineered for commercial use.

ü Best For: Upgrading existing fixtures without rewiring.

ü How They Work: They screw directly into standard E26 (medium) or E39 (mogul) sockets.

ü Why You Need Them: If you already have sockets installed and just want better light or energy savings, this is the cheapest route. However, they don't offer the same protection or coverage as a dedicated fixture.

ü Product Recommendation: The D80 LED Bulbs. These are specifically designed for poultry farms, offering smooth dimming that standard store-bought bulbs can't match.

4. Essential Features Explained

When buying, check the specifications for these three critical features depending on your needs:

① 0-10V Dimming (Crucial for Livestock)

What is it? A standard method to control brightness smoothly from 100% down to 0%.

Why you need it: In a workshop, you might dim lights to reduce glare. In a livestock barn, it is mandatory. You need to simulate sunrise and sunset to keep animals calm and regulate their biological cycles (like egg-laying).

How to buy: Look for "0-10V Dimmable" in the product title. Note: This usually requires installing a separate dimmer switch.

② Motion Sensors (Microwave or PIR)

What is it? A sensor that automatically turns the light on when it detects movement and off when the room is empty.

Why you need it: Great for storage rooms, feed rooms, or garages where your hands are full. It saves electricity by ensuring lights aren't left on by accident.

How to buy: Some UFO High Bays have a port to screw in a sensor. Ask if the sensor is built-in or sold as an add-on accessory.

③ Dusk-to-Dawn Photocell

What is it? A small sensor that detects sunlight. It turns the light on at sunset and off at sunrise automatically.

Why you need it: This is for exterior pole barn lighting. It provides security around the perimeter without you having to flip a switch every night.

How to buy: Look for fixtures labeled "with Photocell" or "Dusk-to-Dawn".

Understanding the Specs: CCT, CRI, and Photoperiod

When shopping for LED pole barn lights, you will see a lot of numbers on the box. You don't need to be a lighting engineer, but you do need to understand these three specs to avoid buying the wrong light.

1. Color Temperature (CCT)

Measured in Kelvins (K), this tells you how "warm" (yellow) or "cool" (blue) the light looks.

u 5000K (Daylight): This is the standard for workshops and garages. It mimics bright noon sunlight. It keeps you alert and makes it easier to see details on blueprints or engine parts.

u 3000K - 4000K (Warm/Neutral White): This is better for livestock barns. A softer, warmer light is less stressful for animals. If you are lighting a swine barn or a horse stable, stick to this range to keep the animals calm.

2. CRI (Color Rendering Index)

Rated on a scale of 0-100, CRI measures how accurately a light reveals colors compared to natural sunlight.

u Why it matters in a shop: If you are rewiring a trailer, you need to tell the difference between a red wire and an orange wire. Low CRI lighting makes them look the same.

u Why it matters for livestock: You need to spot health issues early. High CRI lighting (80+) helps you see discoloration on a horse's hoof or pale combs on poultry, allowing for quicker veterinary intervention.

3. Photoperiod (Light Cycles)

This is critical for farmers. Photoperiod management means controlling how many hours of light your animals get each day.

u The Science: Light affects hormones. For chickens, longer days stimulate egg production. For dairy cows, extending "daylight" hours can increase milk yield.

u The Gear: To do this, you need lights that are compatible with dimmers and timers. You cannot manage photoperiods effectively with simple on/off switches.

Why Upgrade to LED Pole Barn Lights?

If you are still using old Metal Halide bulbs or fluorescent tubes, you are losing money every month. Here is why upgrading to LED is a smart business move.

1. Energy Efficiency (Save Money)

LEDs are about 70-80% more efficient than traditional HID (High-Intensity Discharge) lamps.

Real numbers: A 400-watt Metal Halide fixture can be replaced by a 150-watt LED High Bay. You get the same (or better) brightness for less than half the electricity cost. For a barn running lights 12-16 hours a day, the payback period is often less than a year.

2. Instant On (Works in the Cold)

Old lighting technologies hate the cold. If you have ever flipped a switch in a freezing barn and waited 10 minutes for the lights to flicker to full brightness, you know the frustration.

The LED Advantage: LEDs are instant-on, even in sub-zero temperatures. When you walk into the barn at 5 AM, the lights are ready immediately.

3. Low Heat (Fire Safety)

Old bulbs get incredibly hot. In a pole barn filled with dry hay, sawdust, or fuel, a hot bulb is a serious fire risk, especially if it shatters.

The LED Advantage: LEDs run much cooler. This significantly lowers the risk of accidental fires and keeps the barn temperature more comfortable in the summer.

The Hidden Weakness of Standard LEDs

Here is the uncomfortable truth about the LED industry: Most "agricultural" lights sold today are just repackaged warehouse lights. They rely on materials that are fundamentally unsuited for the chemical reality of a farm.

To understand why they fail, we have to look inside the chip.

1. The Silicone & Phosphor Trap

Standard LED chips use a mixture of phosphor powder and silicone glue to encapsulate the chip and create white light.

u The Problem: Silicone is porous. Under the high heat of operation, the molecular structure of silicone expands.

u The Result: Moisture and corrosive gases penetrate the silicone barrier. Over time, the silicone yellows and cracks (carbonization). This causes "Color Shift"—your bright white light turns dim blue or purple after a year of use. Furthermore, because silicone is a poor heat conductor, heat gets trapped inside, frying the chip from within.

![]()

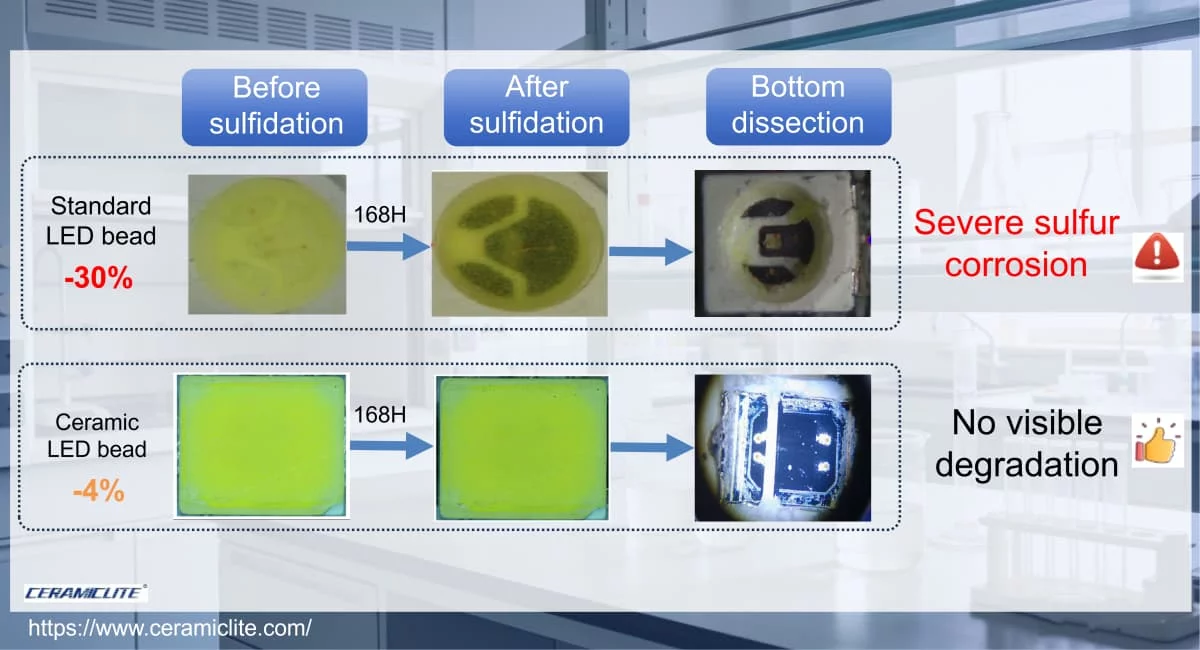

2. Vulnerability to Chemical Attacks (Sulfurization)

Livestock environments are rich in Sulfur (from manure and water) and Ammonia.

u The Reaction: Standard LEDs rely on silver-plated lead frames. Sulfur gas (Hydrogen Sulfide) easily penetrates the silicone packaging and reacts with the silver.

u The Failure: This reaction creates Silver Sulfide (Ag2S), a black compound. The reflective silver turns black, absorbing light instead of reflecting it. The result is rapid, irreversible light loss (lumen depreciation) and eventual total failure.

3. The Housing & Maintenance Nightmare

Standard UFO High Bays are designed for clean warehouses, not dirty barns.

u Corroding Aluminum: Most use die-cast aluminum housings. In an acidic barn environment (ammonia), aluminum oxidizes and corrodes, eventually compromising the waterproof seal.

u Dust Traps: Standard heat sinks have deep, thin fins. These trap feathers, dust, and cobwebs, creating a "thermal blanket" that overheats the fixture.

u Impossible to Clean: Because they have complex fins and standard waterproofing (IP65), you cannot wash them with high-pressure jets. You are forced to leave them dirty, which further reduces lifespan.

Ceramiclite Solution: FTC Technology & Graphene Innovation

We didn't just tweak a standard light; we replaced the core materials. Ceramiclite’s solution is built on two pillars: FTC (Fluorescent Transparent Ceramic) LED Chip Technology and advanced Graphene Composite housings.

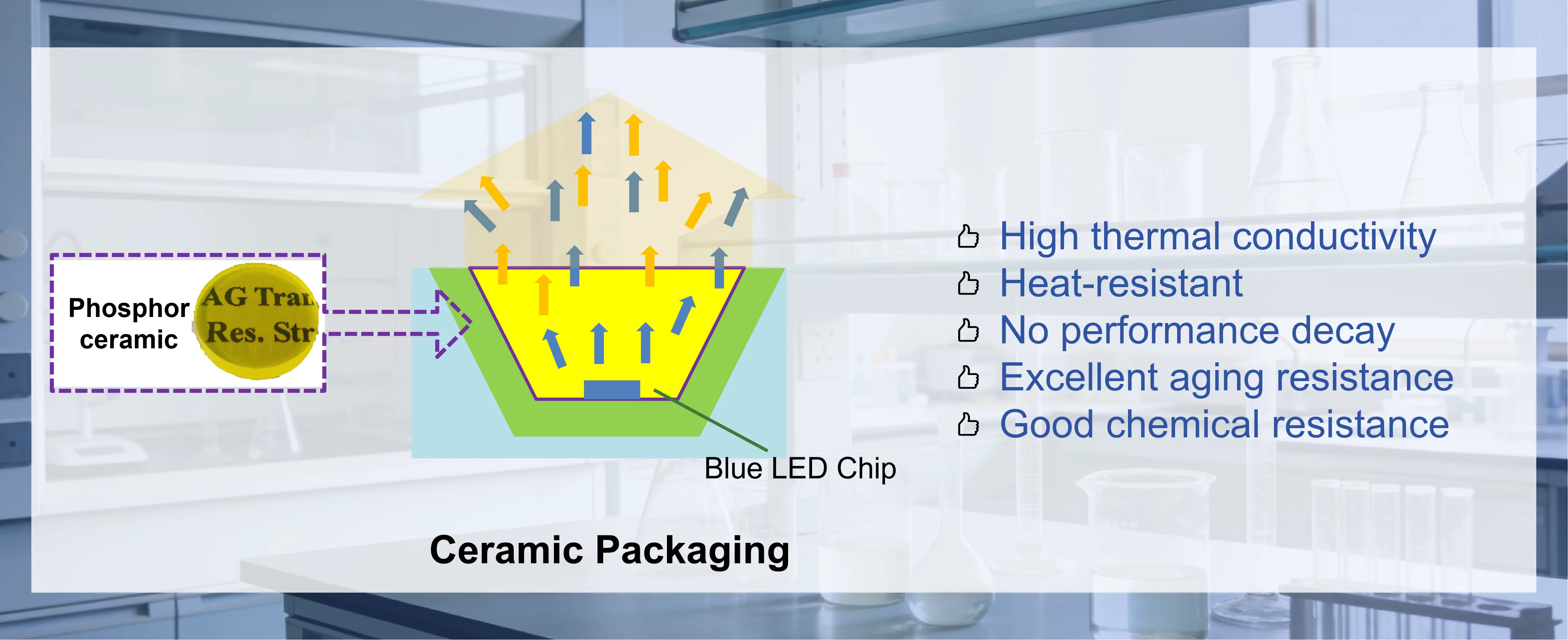

1. What is FTC Technology? (The Chip Revolution)

We have replaced the unreliable "phosphor powder + silicone" mixture with a solid-state Fluorescent Transparent Ceramic. This is a game-changer for industrial and agricultural lighting.

a. Solid-State Durability

FTC is a solid ceramic wafer. It does not use silicone glue. This gives it exceptional physical and chemical stability, making it immune to the aging and cracking that plagues standard LEDs.

b. Unmatched Thermal Conductivity

Silicone is an insulator. FTC ceramic is a conductor. It has a thermal conductivity of up to 10 W/m·K, and the thermal resistance is 50 times lower than traditional chips.

Why this matters: It pulls heat away from the light source instantly. Even under high power, the surface temperature remains low (e.g., only ~89°C at stable states for high-power COB), drastically extending lifespan.

c. Zero Color Shift

Because ceramic doesn't degrade like silicone, the light source maintains its original color temperature for years. There is no "drifting" to blue or purple.

2. Extreme Chemical Resistance

We tested FTC chips against the harshest elements.

The Sulfur Test: Under strictly controlled testing (15ppm Hydrogen Sulfide concentration for 168 hours), the Ceramiclite FTC chip surface showed no change.

The Result: Our chips are virtually impervious to acid, alkali, ammonia, and sulfur. This makes them the only logical choice for poultry and swine facilities.

3. Real-World Longevity (The Data)

This isn't just marketing; it's verified by LM-80 testing.

<5% Degradation: After 100,000 hours of operation, FTC-based LEDs show less than 5% luminous attenuation. Standard LEDs often lose 30% brightness in a fraction of that time.

This allows us to offer industry-leading warranties of 5 to 8 years.

4. Beyond the Chip: The HB01 Graphene Advantage

The chip is protected by an equally advanced housing. Our HB01 High Bay eliminates the weaknesses of aluminum.

u Graphene Material: We infuse the housing with graphene. This material dissipates heat faster than die-cast aluminum and is chemically inert—it will not corrode in ammonia environments.

u Smooth Surface Design: The HB01 is designed without the deep, dust-trapping fins of standard lights. Dust and feathers slide off, keeping the fixture running cool.

u IP69K Washdown Ready: These lights are sealed to the highest standard. You can clean them with high-pressure, high-temperature water jets (1450 psi at 80°C) without fear. This is essential for biosecurity in livestock farming.

(Note: For low-ceiling applications, our T16 Tri-proof barn lights utilize specialized anti-ammonia plastic to ensure the same level of protection.)

How to Calculate Pole Barn Lighting Precisely?

Don't guess. A poorly planned layout creates shadows that can make work dangerous or startle livestock.

While you can run a quick estimate, we recommend a more scientific approach to ensure you aren't wasting money on too many lights or straining your eyes with too few.

Step 1: Define Your Target Foot-Candles (FC)

Lighting needs vary by task. Based on IES (Illuminating Engineering Society) standards, here are the targets you should aim for on your working surface (usually 30 inches off the floor):

Ø General Storage / Farm Machinery: 10 - 20 FC

Ø Livestock (General Handling): 20 - 30 FC

Ø Workshops / Repair Bays: 50 - 75 FC

Ø Detail Work (Painting/Fine Assembly): 75 - 100 FC

Step 2: Select the Right Fixture

Not all lumens are created equal. For efficiency, choose High Bay lights with a luminous efficacy of >130 lm/W.

Ø Color Temperature: Stick to 4000K-5000K for clarity.

Ø CRI: Aim for CRI ≥ 80 if color accuracy matters (e.g., matching paint or checking animal health), though CRI ≥ 70 is acceptable for general storage.

Ø Protection: Ensure IP65 or higher to resist dust and moisture.

Step 3: The Scientific Calculation Formula (Core)

To get a precise number, we need to account for light that gets absorbed by walls or lost over time (dirt accumulation).

Formula:

Number of Fixtures = (Area × Target FC) / (Lumens per Fixture × CU × MF)

Understanding the Factors:

CU (Coefficient of Utilization): How much light actually reaches the floor based on wall reflection.

For a typical pole barn with light-colored metal walls, use 0.6. For darker wood walls, use 0.5.

MF (Maintenance Factor): Accounts for lumen degradation and dirt buildup over time.

With regular cleaning, use 0.8. For a conservative estimate (or dusty environments), use 0.7.

Example Calculation:

Let’s light a 30x40 ft (1,200 sq. ft.) workshop.

Target: 50 FC (Workshop standard).

Fixture: Ceramiclite HB01 (20,000 Lumens).

Assumptions: Light metal walls (CU = 0.6), relatively clean (MF = 0.8).

Total Lumens Required = 1,200 sq. ft. × 50 FC = 60,000 Lumens

Effective Lumens per Light = 20,000 × 0.6 × 0.8 = 9,600 Lumens

Fixtures Needed = 60,000 / 9,600 = 6.25

Result: You need 7 fixtures to guarantee your light levels meet the 50 FC standard.

Step 4: Layout Best Practices

Ø Mounting Height: Hang lights high enough to clear trusses but low enough to maximize brightness.

Ø Spacing (S/MH Ratio): Check the manufacturer’s "Spacing-to-Mounting Height" ratio. If unavailable, a 1:1 ratio (spacing equals mounting height) is a safe starting point to ensure uniform overlap.

Ø Wall Distance: Place the first row of lights at a distance from the wall equal to 1/2 of your fixture spacing. This lights up the perimeter workbenches without wasting light on the wall itself.

Ø Zoning: Wire your lights on separate switches (e.g., Storage Zone vs. Workbench Zone). There is no need to light the whole barn at 100% brightness just to grab a screwdriver.

Need a Guarantee? Let Us Simulate It.

The calculation above is based on standard assumptions. However, every barn is unique—truss obstructions, wall colors, and machinery layouts all affect light.

Do you want a professional lighting plan that guarantees zero shadows and no glare?

Contact Ceramiclite today. Send us your barn dimensions, and our engineers will create a FREE DIALux lighting simulation tailored specifically to your space. Get it right the first time.

Conclusion

When building or upgrading a pole barn, lighting is often the last thing on the budget list. It is tempting to grab the cheapest "high-lumen" lights you can find online.

But as we have seen, brightness is only half the story.

If your pole barn is just a garage, standard LEDs are fine. But if your barn houses livestock, chemicals, or heavy machinery, those standard lights are on a countdown to failure from day one. The invisible enemies—ammonia, sulfur, heat, and moisture—will degrade the plastic and corrode the aluminum.

By choosing Ceramiclite’s FTC technology and Graphene-infused fixtures, you aren't just buying lights; you are investing in infrastructure.

ü You get fixtures that resist acid and corrosion for a decade, not just a year.

ü You get the ability to wash them down with high-pressure jets without fear.

ü You get the precise spectral control needed to keep your animals healthy and productive.

Your pole barn is built to last a lifetime. Your lighting should be too.

Ready to future-proof your barn?

Browse our specialized Pole Barn Lighting Collection or reach out to our team for a custom solution.

FAQ

1. How many lights do I need in my pole barn?

It depends entirely on the size and use. For a simple storage barn, you might only need 10-20 foot-candles (FC) of light. For a detailed workshop, you need 50+ FC. As a rule of thumb, aim for roughly 50 lumens per square foot for workshops. Use the formula in Chapter 7 to calculate exactly based on your square footage, or ask us for a free layout.

2. What is the best lighting for a 30x40 shop?

For a 30x40 ft shop (1,200 sq. ft.) with a 12-16 ft ceiling, we typically recommend 4 to 6 units of Ceramiclite 150W HB01 UFO High Bays. This setup provides excellent brightness for general mechanical work. If the ceiling is lower (under 10 ft), use rows of T5 Linear Lights to avoid shadows.

3. How many lumens do I need for a 40x60 shop?

For a 40x60 ft shop (2,400 sq. ft.), you need approximately 120,000 lumens to achieve a bright 50 foot-candle workshop standard. This typically requires 6 to 8 Ceramiclite HB01 High Bays. If used only for storage (20 FC), about 48,000 lumens (3-4 fixtures) is sufficient.

4. How many lumens do I need to light a 30x40 shop?

To achieve a standard workshop brightness of 50 Foot-Candles, you generally need around 60,000 to 75,000 total lumens. This assumes light-colored walls and ceilings. If your interior is dark wood or unlined metal, you may need to increase this by 20% to account for light absorption.

5. What is the best lighting layout for a pole barn?

The best layout minimizes shadows. For open workshops, use a Grid Layout (e.g., 2 rows of 3 lights) to ensure uniform coverage. For aisles or dairy stanchions, use a Linear Layout running parallel to the work area. Always aim for a 1:1 spacing-to-height ratio—if lights are mounted 15 ft high, space them 15 ft apart.

6. Is 5000K or 6000K brighter?

Technically, they have similar brightness (lumens), but our eyes perceive them differently. 5000K (Daylight) is the industry standard for workshops—it is pure white and comfortable. 6000K has a blue tint; while it looks "glaringly" bright, it can cause more eye strain, distort colors, and is generally not recommended for professional workspaces. We recommend 5000K for detailed work and 4000K for livestock comfort.

7. How to choose LED lights for dairy barns?

Dairy barns are high-ammonia environments. Do not use standard aluminum LEDs. You must look for fixtures that are:

a. Corrosion-resistant (like Ceramiclite FTC chips and Graphene housings).

b. IP69K rated (to withstand high-pressure washdowns).

c. Dimmable (to extend photoperiods for higher milk yield).

8. Are LED barn lights difficult to install?

No, most are designed for easy installation. UFO High Bays usually come with a simple hook mount—just hang them from a truss chain and plug them in. Linear Lights often use snap-on surface clips or suspension cables.

Safety Tip: Always ensure your wiring is rated for the environment (e.g., using conduit in wet areas).

_thumb.jpg)