Poultry Farm Upgrades to Ceramiclite T21 LED Lights

Poultry Farm Upgrades to Ceramiclite T21 LED Light

Customer Background

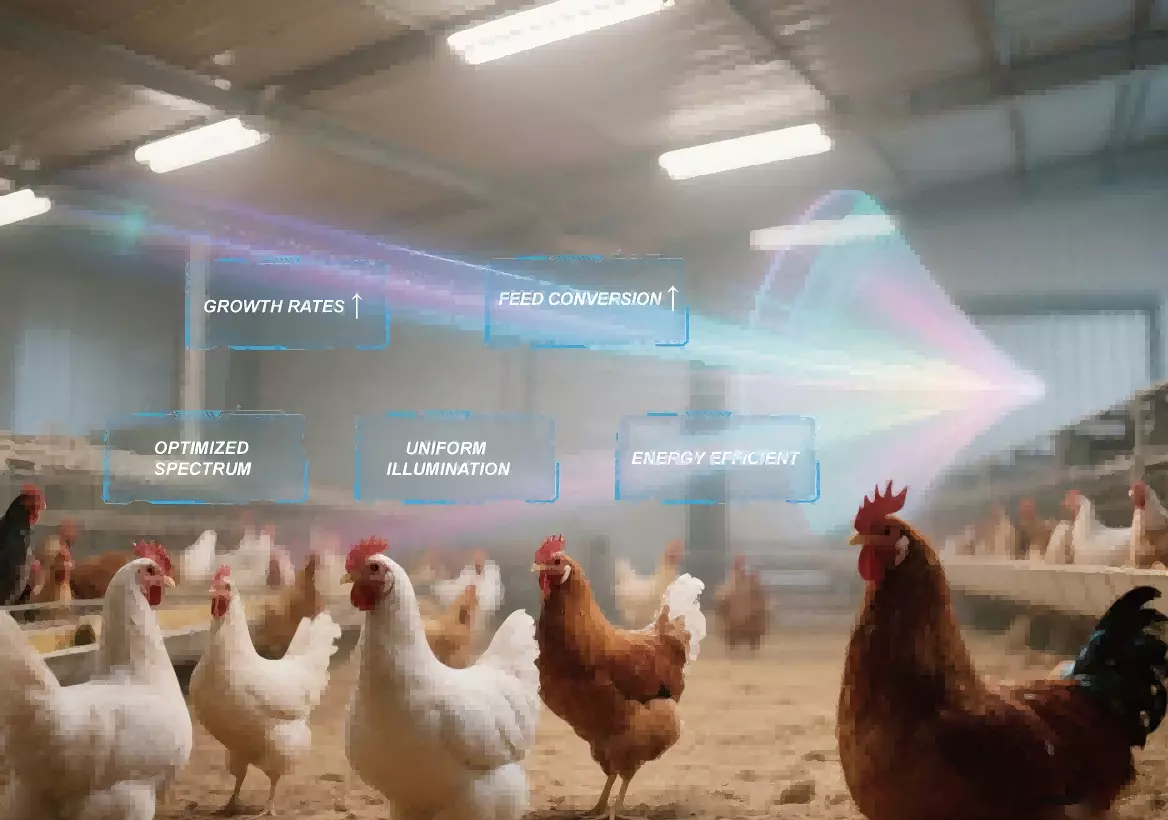

A mid-scale broiler farm operating four grow-out houses (totaling roughly 12,000 m²) had been relying for years on a mix of old fluorescent tubes and aging metal-halide fixtures. As the equipment deteriorated, the farm began facing uneven lighting, frequent bulb failures, and rising electricity bills. To stabilize the barn environment and improve flock performance, the farm decided it was time to modernize its lighting system—aiming for lower energy use, more consistent illumination, and healthier, more uniform bird growth.

-

.webp)

High Energy Consumption

-

Frequent lamp replacements and maintenance downtime

-

Uneven lighting with dark corners, causing bird crowding and stress

-

Excess heat from HPS/MH lamps, increasing ventilation load

-

Poor light spectrum control, affecting feed intake, growth rate, and behavior

Our Solution

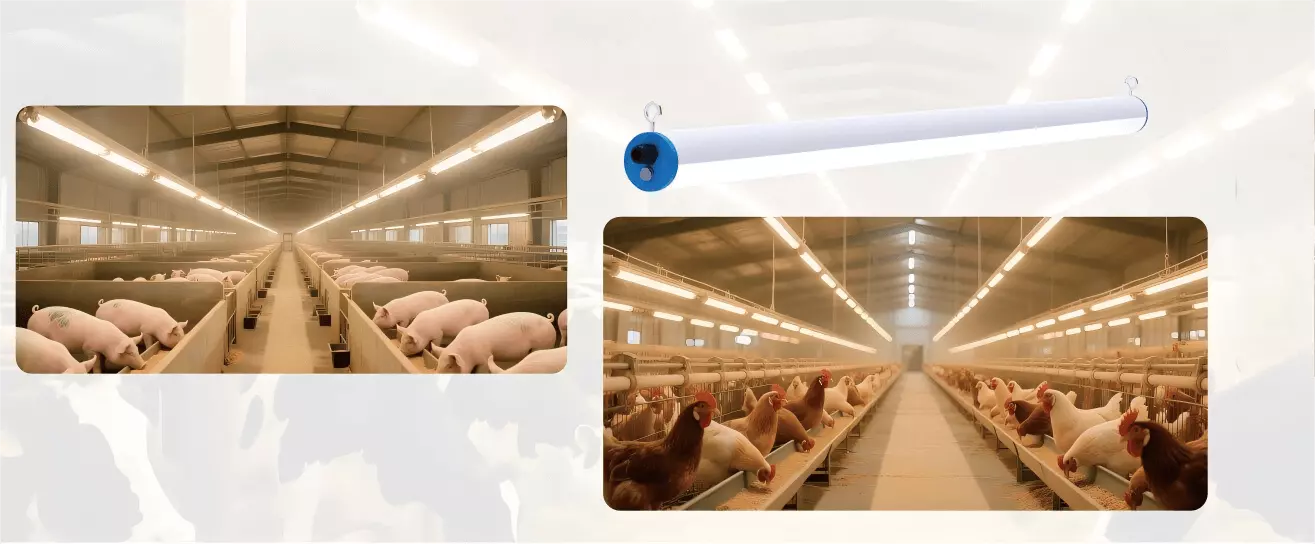

Ceramiclite designed and deployed a complete poultry lighting system using T21 LED barn lights, built with corrosion-resistant housings and fully IP66-sealed construction. The setup is engineered to withstand high humidity, dust, and ammonia levels commonly found in poultry houses, ensuring reliable long-term operation with minimal maintenance.

Key Solution Highlights

-

Uniform lighting layout achieving U₀ ≥ 0.6–0.7 across the entire house

-

.webp)

Adjustable light intensity and spectrum tailored to broiler growth stages

-

.webp)

Soft, flicker-free warm lighting to reduce stress and aggressive behavior

-

Smart dimming with programmed sunrise/sunset transitions

-

Timer-based automatic photoperiod control for each production cycle

Outcome & Benefits

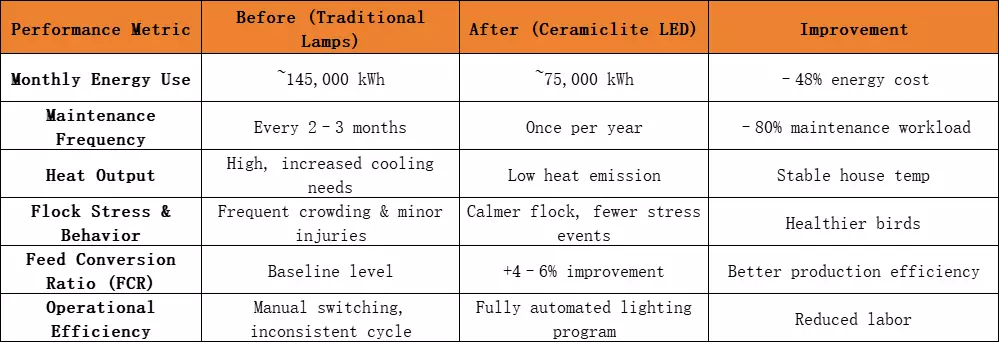

This project shows how replacing outdated barn lighting with Ceramiclite T21 high-efficiency LED fixtures led to practical improvements in daily farm operations—more consistent flock behavior, easier system management, and noticeably lower long-term energy and maintenance costs.

Measured Improvements

Project Implementation Details

-

Site Assessment & Lighting Audit

Before installation, the Ceramiclite engineering team conducted a full audit of the poultry house, including:1). Existing illuminance levels (average 18–25 lux with uneven distribution)2). Uniformity ratio as low as 0.35, causing bright–dark spots3). Mounting height of 3.5–4.2 meters4). Dust, ammonia, and humidity levels common in poultry environments5). Existing wiring & power distribution checks to ensure compatibility with T21 fixturesThis assessment guided the optimal fixture layout and dimming configuration. -

.webp)

Lighting Design & Simulation

Based on measured parameters, a custom lighting plan was created using Dialux:

1). Lighting target: 30–40 lux for broilers; 20–25 lux for resting periods2). Uniformity target: ≥0.653). Layout: 2 rows per bay, evenly spaced to eliminate shadows4). Beam angle & optics: Anti-glare, wide-beam design of T21 for smooth distribution5). Dimming curve: Custom sunrise–sunset cycle programmed to reduce flock stressThe simulation ensured the system met both animal welfare standards and energy efficiency goals.

-

.webp)

Installation & Deployment

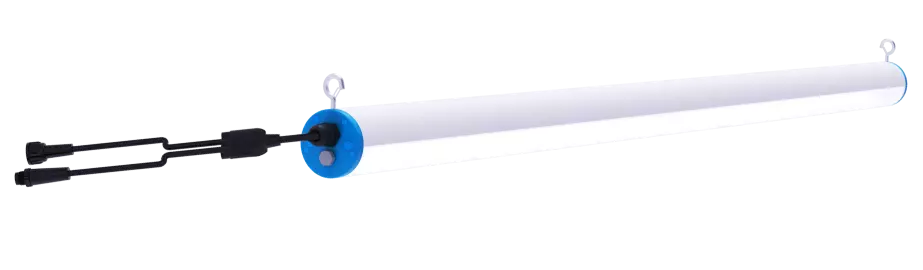

The farm upgraded to Ceramiclite T21 poultry LED lights with the following configuration:

1). Total fixtures installed: 86 units2). Mounting height: 3.8 meters3). Cable system: Moisture-resistant and ammonia-proof connectors4). IP rating: IP65 sealed luminaires for continuous operation in dusty/humid houses5). Power control: Integrated with the farm’s existing dimmer controller6). Installation time: Completed in 1.5 days without disrupting daily feeding schedulesThe lightweight design of T21 allowed technicians to complete mounting quickly and safely. -

On-Site Testing & Commissioning

After installation, the engineering team performed full system calibration:

Measured average illuminance:Before: 22 luxAfter: 38 luxUniformity:Before: 0.35After: 0.72Color rendering (CRI): Improved from <70 to 80+Power draw:Previous system: ~4.2 kWT21 system: 2.3 kW (45% reduction)A gradual dimming program was tested on-site to verify smooth transitions during feeding and resting periods.

Testimonial

Product Recommendation

-

T21 LED Poultry Light

The Ceramiclite T21 LED Poultry Light delivers optimized barn lighting tailored for poultry and livestock environments — providing consistent, flicker-free illumination that promotes animal welfare and uniform growth while withstanding humid, ammonia-rich agricultural conditions.

_thumb.jpg)

.webp)