Precision Lighting for Poultry Production

.png)

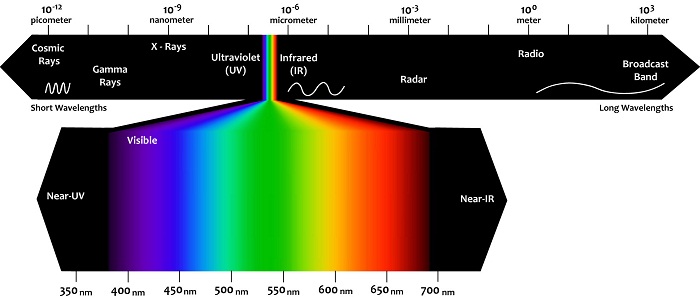

Precision lighting is redefining modern poultry production. Instead of providing simple illumination, it creates biologically optimized environments that directly influence flock performance. Chickens perceive light differently from humans, with a visual range of ~300–700 nm and sensitivity to ultraviolet (UV). Within this range, light spectrum, intensity, and timing play a critical role in shaping feeding behavior, stress levels, reproductive success, and overall flock health.

By adopting structured precision lighting programs, poultry producers move beyond basic visibility to achieve measurable, repeatable outcomes in growth, welfare, and product quality.

Click to Jump:

1. The Science Behind the Spectral Impact of Precision Lighting

2. Engineering an Effective Precision Lighting Environment

3. The Path Forward: Adaptive Precision Lighting in Poultry Farming

1. The Science Behind the Spectral Impact of Precision Lighting

At the heart of precision lighting is the ability to harness specific light wavelengths to deliver targeted biological responses in poultry farm. This approach shifts from generic illumination to customized spectral programs grounded in avian physiology, enabling producers to optimize flock outcomes with measurable precision.

1.1 Ultraviolet (350–400 nm): The Vitality Catalyst

.png)

Image source: sciencenotes.org

Ultraviolet light helps replicate the benefits of natural sunlight, often lacking in modern enclosed poultry houses. Research shows that controlled UV exposure supports vitamin D3 synthesis, improves calcium metabolism, and contributes to stronger skeletal health—important for reducing deformities in fast-growing broilers.

Practical trials suggest that providing just one hour of UV light daily during the laying cycle can increase eggshell thickness by ~0.05 mm and reduce the incidence of soft-shell eggs to below 0.5%. Beyond skeletal effects, UV also assists birds in distinguishing nutrient-rich feed and identifying healthy flock mates, encouraging natural social behaviors and reducing aggression.

1.2 Blue (480–490 nm): The Calming Signal

Blue wavelengths in precision lighting exert a calming effect, lowering corticosterone—the primary stress hormone in poultry. This contributes to steadier flock behavior and fewer aggressive interactions.

.png)

Image source: theraspecs.com

For example, applying blue-dominant lighting three days before harvest has been shown to reduce escape attempts by up to 70% and improve meat tenderness by around 15%. For high-density operations, integrating blue spectra is a proven strategy to enhance welfare and improve processing efficiency.

1.3 Green (530–550 nm): The Growth Accelerator

Green light stimulates early cellular and muscular development, laying the foundation for healthier growth. Several studies report that green wavelengths activate satellite cells in muscle tissue, boosting skeletal and muscular expansion.

Image source: chroma.com

During brooding, providing 18 hours of green-enriched lighting per day has been associated with tibia length increases of ~8% and early body weight gains of ~12%. Such improvements contribute to better feed efficiency and reduced time to market.

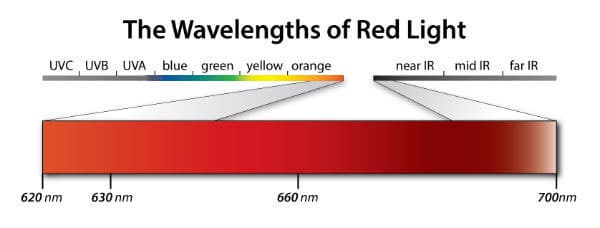

1.4 Red (660–680 nm): The Metabolic Driver

Red light directly influences the hypothalamus, stimulating appetite centers and reproductive pathways. This spectral input enhances feed intake and supports hormonal activity critical for breeding success.

Image source: redlightman.com

In breeding programs, six hours of red-dominant lighting per day has been reported to increase feed consumption by ~20% and raise fertility rates to as high as 90% under optimal conditions. By linking wavelength to biological function and KPIs, precision lighting provides a reproducible framework to balance growth and reproduction.

Precision lighting establishes a direct pathway from wavelength → biological function → performance outcome, enabling poultry producers to design repeatable and scientifically grounded lighting programs.

2. Engineering an Effective Precision Lighting Environment

An effective precision lighting system requires more than bulb selection—it integrates spectrum, timing, and technology to provide uniform, stress-free conditions across the flock's lifecycle.

Key components include:

Tunable LED arrays: Deliver dynamic spectral blends tailored to each growth phase.

Circadian controllers: Synchronize artificial cycles with birds’ natural rhythms.

UV modules: Compensate for the absence of natural sunlight in closed houses.

Intensity zoning: Prevents overcrowding stress and reduces aggression in high-density flocks.

Flicker control (>300 Hz): Ensures stress-free environments by matching poultry’s high flicker sensitivity.

Implementation guidelines:

0–2 weeks (brooding): 20–50 lux to stimulate activity and exploration.

Grow-out phase: 10–20 lux to maintain calm and conserve energy.

Always use dimmable precision lighting to create gradual transitions and avoid sudden intensity shifts that may trigger stress.

3. The Path Forward: Adaptive Precision Lighting in Poultry Farming

As the poultry industry advances toward precision agriculture, adaptive precision lighting is becoming a cornerstone technology. Unlike traditional static systems, adaptive lighting dynamically adjusts spectra, intensity, and photoperiod based on bird age, behavior, and biological markers. This data-driven approach enables producers to maximize both animal welfare and production efficiency.

Recent field trials demonstrate the impact of spectral sequencing: applying green light during the brooding phase to stimulate early skeletal and muscular development, followed by red light during the grow-out phase to enhance growth rate and feed efficiency. Results have shown double-digit improvements in feed conversion ratio (FCR)—a critical performance metric in modern poultry farming.

In an era of rising feed costs, stricter animal welfare regulations, and sustainability demands, spectral optimization through precision lighting offers a proven, science-backed solution. It not only lowers operational costs and mortality but also helps producers achieve consistent egg and meat quality, aligning profitability with long-term sustainability goals.

4. Conclusion

Integrating precision lighting into spectrum management, intensity control, and photoperiod scheduling empowers poultry producers to unlock measurable improvements across flock performance and farm profitability. By tailoring light color, strength, and duration to the birds' biological needs, farms can achieve:

Stronger skeletal development through optimized wavelengths that stimulate bone growth and reduce leg disorders.

Faster and more uniform growth, as consistent light cues promote regular feeding and activity patterns.

Lower mortality rates by minimizing stress and supporting stronger immune responses.

Higher consistency in both egg and meat quality, ensuring reliable output that meets commercial standards.

Today, precision lighting is no longer just a supplementary management tool—it has become a cornerstone of modern poultry production. It supports producers in balancing animal welfare with efficiency, reducing energy costs, and advancing toward more sustainable and profitable farming systems.

5. Poultry Lighting Bulbs

The D80 poultry lighting bulbs are designed to deliver precision lighting excellence across the full UV-to-red spectrum.

Spectrum optimization: Supports every flock stage, from brooding to breeding.

Flicker-free performance (>300 Hz): Provides smooth sunrise and sunset transitions, reducing stress.

Durability and efficiency: Built for longevity, reducing maintenance costs and energy consumption while ensuring uniform coverage.

Upgrade to D80 LED light bulbs for poultry lighting and implement standardized precision lighting solutions to achieve measurable improvements in flock welfare, productivity, and sustainability.

_thumb.jpg)