Photometric Plan Guide: For Compliant, Efficient Lighting

Table of Contents

When Do You Need a Photometric Lighting Plan?

4 Key Reasons to Includes Photometric Plans

How to Read a Photometric Plan & Chart?

How We Conduct a Professional Photometric Study?

Introduction

You wouldn’t pour a concrete foundation without a structural blueprint. You shouldn’t install commercial lighting without a Photometric Plan.

For architects, facility managers, and contractors, lighting is no longer just about "making it bright." It is about mandatory compliance and investment protection. A proper lighting design is the difference between passing a final building inspection and facing costly tear-downs due to light trespass violations. It is the specific calculation that ensures your project meets safety codes while minimizing your energy bill.

Whether you are retrofitting a warehouse or planning a new parking lot, skipping the analysis phase is a financial risk.

In this guide, we will demystify the photometric study, explain how it optimizes your Capital Expenditure (CapEx), and show you how to ensure your project is compliant before you buy a single fixture.

v Pro Tip: Don't have CAD drawings? Don't worry. At the end of this guide, we’ll explain how CeramicLite offers FREE photometric analysis including professional site surveys and data collection.

What is a Photometric Plan?

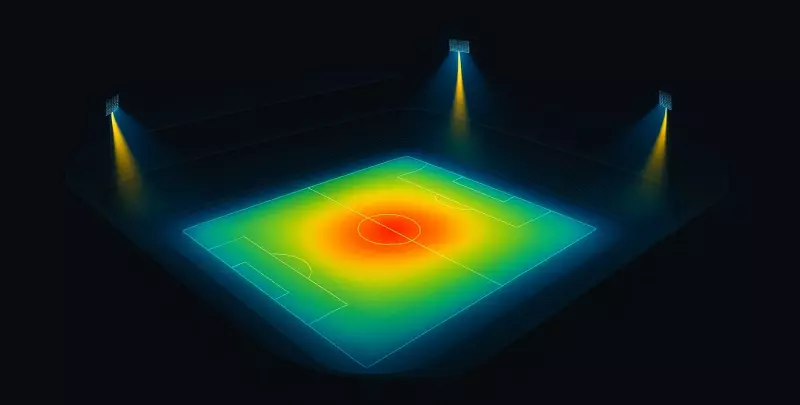

A photometric plan (also known as a photometric analysis or study) is not just a heat map; it is a precise digital simulation of how light will behave in a specific physical space.

Unlike a standard CAD layout which simply shows where fixtures are placed, a photometric plan calculates how much light hits every square foot of your surface. It accounts for ceiling height, surface reflectance, and potential obstructions.

The Science Behind the Simulation: IES Files

The accuracy of any photometric study relies on data. This data comes from IES Files (Illuminating Engineering Society).

Think of an IES file as the "DNA" of a specific LED fixture. It is a standard format (IESNA LM-63) that contains critical photometric data, including:

Ø Luminous Intensity Distribution: How the light spreads (beam angle).

Ø Lumen Output: The total amount of light emitted.

By importing these IESNA LM-63 files into advanced simulation software, we can predict exactly how a CeramicLite high bays or sports lights will perform in your specific environment—down to the decimal point.

When Do You Need a Photometric Lighting Plan?

While simple residential projects might rely on guesswork, commercial and industrial projects require precision. Here are the four primary scenarios where a photometric plan is essential:

1. Regulatory Permits & Municipal Codes

Most cities in the US and Europe now enforce strict "Dark Sky" ordinances. To obtain a building permit, you often must submit a photometric site plan proving that your light will not "trespass" onto neighboring properties (Light Trespass). Without this report, your permit may be denied.

2. Large Commercial & Industrial Projects

For expansive areas like parking lots, logistics centers, or sports stadiums, a trial-and-error approach is impossible. You need to verify light levels across vast distances to ensure visibility.

3. Green Building Certifications (LEED / WELL)

If your project is aiming for LEED (Leadership in Energy and Environmental Design) or WELL certification, you must adhere to strict guidelines regarding light pollution reduction and energy efficiency. A detailed photometric study is the only way to document these credits.

4. Safety & Liability (OSHA Compliance)

In workplaces, poor lighting causes accidents. A photometric plan ensures your facility meets OSHA lighting standards (Occupational Safety and Health Administration). By eliminating dark spots and shadowing, you protect your workforce and reduce the liability risk of slip-and-fall lawsuits.

4 Key Reasons to Includes Photometric Plans

Why should you spend time on a simulation? Because in the lighting world, data equals money.

1. Optimize CapEx & OpEx (Financial Efficiency)

This is the biggest value driver for business owners:

Ø Optimize CapEx (Capital Expenditure): Don't buy more lights than you need. A photometric plan calculates the exact number of fixtures required to hit your target lux/fc levels. We often help clients reduce their fixture count by 20% just by optimizing placement.

Ø Reduce OpEx (Operational Expenditure): By selecting the most efficient optics and placement, you reduce total energy consumption, lowering your electricity bill for years to come.

2. Ensure Code Compliance

Violating local light ordinances can result in fines or mandates to remove and replace installed fixtures. A photometric study is your insurance policy against these costly mistakes.

3. Risk Mitigation: Eliminate Shadows

Safety isn't just about average brightness; it's about uniformity. A plan identifies potential shadows caused by racking, machinery, or trees before installation, allowing you to adjust the design for maximum safety.

4. Visualize Success (Proof of Concept)

"Bright enough" is subjective; Foot-candles are objective. A photometric plan provides a visual representation (3D renderings and false-color maps) that aligns the expectations of architects, owners, and installers. You get to see the result before spending a dollar.

How to Read a Photometric Plan & Chart?

Receiving a photometric report can be overwhelming. It often looks like a topographic map covered in numbers. However, you don't need to be an engineer to understand the three most critical components that determine the quality of your lighting.

1. Understanding the Metrics: Foot-Candles (fc) vs. Lux

The most common number you will see on the plan is the Foot-Candle (fc), which is the standard unit of measure for illuminance in the United States.

l Definition: One foot-candle equals one lumen of light density per square foot.

l Metric Conversion: If you are working on international projects, you might see Lux (lx). The conversion is simple: 1 fc ≈ 10.76 lux.

l What to look for: Check the "Calculation Points" grid. Are the numbers meeting your target? For example, a general warehouse floor might need 30 fc, while detailed assembly work might require 75 fc.

2. The Critical "Uniformity Ratio"

Brightness is easy; uniformity is hard. This is the single most important indicator of a professional design versus a cheap one.

l What it is: The ratio between the average brightness and the minimum brightness (Avg/Min) or the maximum and minimum (Max/Min).

l Why it matters: A low uniformity ratio means your eye has to constantly adjust between bright spots and dark patches, causing eye fatigue and safety hazards.

l The Benchmark: For a standard commercial parking lot, a typical target is a Max/Min ratio of 15:1 or better. If your report shows a ratio of 50:1, you have dangerous "hot spots" and deep shadows—send it back for redesign.

3. Deciphering Visuals: Isolux Lines

Look for the curved lines on the chart. These are Isolux Lines (or Isocandela lines).

Think of them like elevation lines on a hiking map, but instead of altitude, they show brightness. They connect all points with the same light level. These lines help you instantly visualize the "drop-off"—how quickly the light fades as you move away from the pole.

How We Conduct a Professional Photometric Study?

At CeramicLite, we don't just plug numbers into a generic calculator. We follow a rigorous 4-step engineering process to ensure your plan is buildable, compliant, and cost-effective.

Step 1: As-Built Documentation & Site Survey (Our Specialty)

Garbage in, garbage out. A simulation is only as good as the data you start with.

Many clients come to us without current CAD drawings. That is not a problem. We offer professional site survey services to create "As-Built Documentation." We measure the actual physical environment—pole locations, building heights, and obstructions—to ensure the simulation reflects reality, not just a theoretical rectangle.

Step 2: Needs Analysis based on IESNA Standards

We determine the correct light levels based on IESNA Recommended Practices (Illuminating Engineering Society of North America).

l Lighting a sports stadium? We refer to RP-6 (Sports and Recreational Area Lighting) to ensure uniform visibility for players and spectators.

l Optimizing a livestock farm? We apply specialized agricultural lighting guidelines to enhance animal welfare and productivity.

l Lighting an industrial floor? We consult RP-33 for safe industrial environments.

We ensure your targets meet the specific safety and operational standards for your industry.

Step 3: Fixture Selection & IES File Curation

Every LED fixture has its unique features. We analyze your needs and select the specific CeramicLite fixtures that offer the best optic distribution for your space. We strictly verify our IESNA LM-63 data to ensure the simulation matches the real-world performance.

Step 4: Advanced Simulation (DIALux)

We use DIALux, the industry-standard software for lighting calculation. This allows us to account for complex variables like "Light Loss Factors" (LLF) and surface reflectance. The result is a plan that stands up to scrutiny from city inspectors and safety auditors.

Conclusion

A photometric plan is the bridge between a vague idea and a successful, compliant lighting project. It protects you from regulatory fines, eliminates safety risks, and ensures every dollar of your CapEx is spent efficiently.

Don't guess with your lighting. Whether you have a complete set of CAD drawings or just a rough idea of what you need, CeramicLite is here to help.

Ready to see your light before you buy it?

Click the button below to request your Free Photometric Analysis. If you lack data, ask about our site survey services—we’ll handle the measuring for you.

[ Request Your Free Photometric Plan Now ]

_thumb.jpg)