Why Choose Ceramiclite LED Lighting Solution?

In extreme livestock, sports and industrial environments, lighting is not a commodity, it is infrastructure.

Ceramiclite develops advanced LED lighting systems with fluorescent transparent ceramic LED material engineered to operate reliably under high temperature, high corrosion, and chemically aggressive conditions where conventional LED technologies degrade, drift, or fail prematurely.

Our advantage is not a single component or feature. It is a materials-first engineering approach that transforms ceramic science into long-term, deployable lighting reliability.

Built on Advanced Ceramic Materials & Scientific Engineering

In sulfur-rich, ammonia-heavy, high-heat, or corrosive environments, traditional LED packages, typically based on silicone encapsulation and organic phosphors suffer from:

Rapid lumen depreciation

Color shift and optical instability

Accelerated corrosion and packaging degradation

Shortened service life and frequent maintenance

Ceramiclite addresses these failures at the material level, not through incremental product tuning.

By integrating transparent ceramics, phosphor ceramics, and composite ceramic phosphor technologies into the LED core, we achieve a fundamentally different performance profile:

Superior thermal management:

Ultra-low thermal resistance enables efficient heat dissipation under continuous high-power operation.Exceptional lumen stability:

Minimal light decay and color drift, even under elevated ambient temperatures.Chemical and corrosion resistance:

Proven durability against sulfur, ammonia, acidic vapors, and harsh industrial atmospheres.

.jpg)

In real-world operating environments, Ceramiclite LED lighting systems with fluorescent transparent ceramic LED material deliver a significantly extended service life in conditions where standard LED solutions typically fail prematurely. Performance remains stable and predictable over time, not merely at the point of installation, with consistent lumen output and optical reliability throughout the system's lifecycle. As a result, maintenance cycles are substantially reduced, operational interruptions are minimized, and long-term operating costs are better controlled.

At Ceramiclite, we do not optimize around inevitable failure, we engineer it out at the material level.

From Materials & Optics to Deployable Engineering Solutions

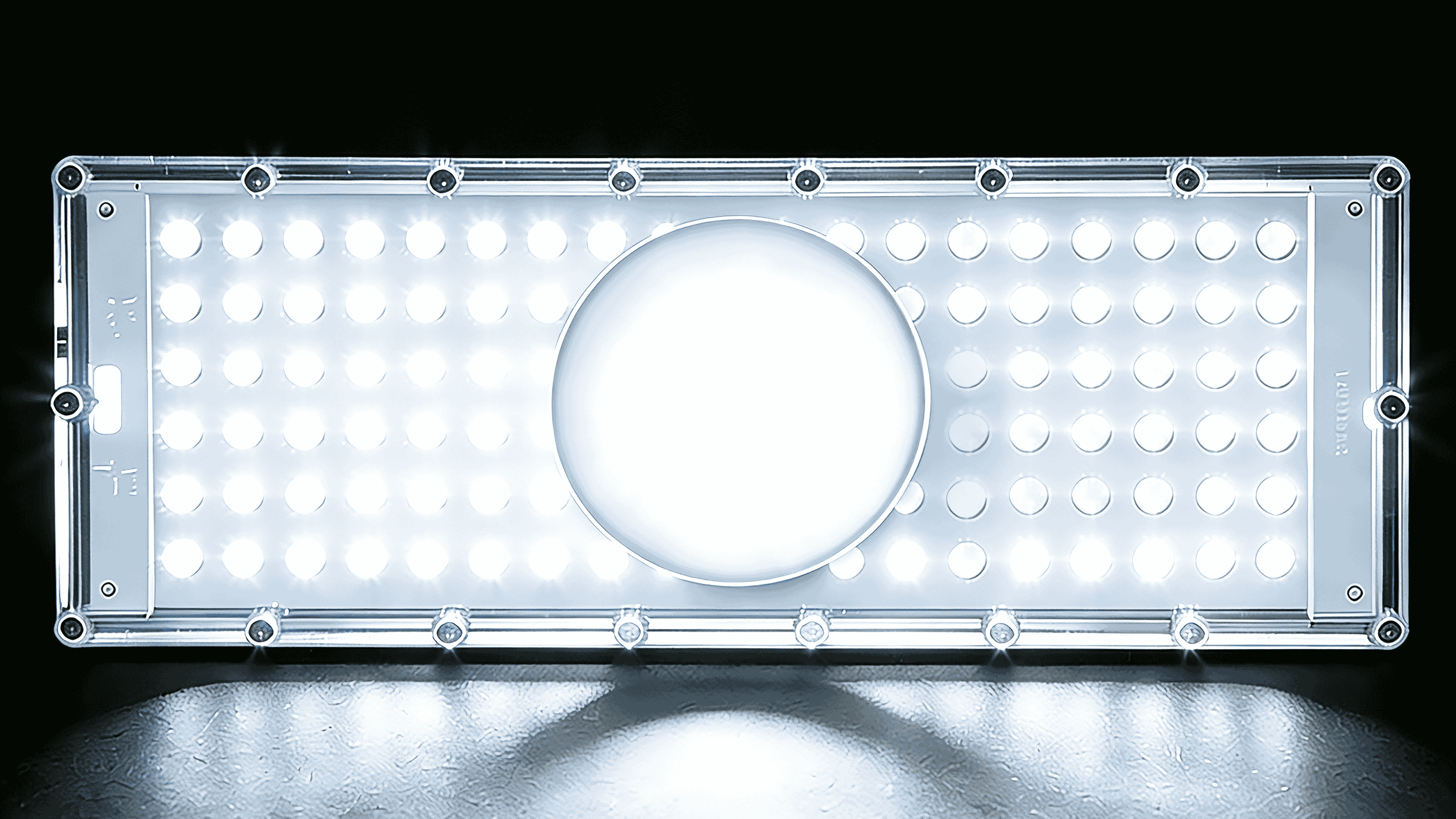

Product Level: Engineering the Luminaire Itself

At the product level, Ceramiclite starts with the luminaire as a complete working unit, not just a light engine.

Each fixture is designed around high-power ceramic LED cores, with optical lenses, housings, and thermal paths developed as an integrated system. Optical distributions are selected based on real application needs, such as wide-area uniformity, glare limitation, or long-throw illumination, rather than generic beam angles. At the same time, thermal structures are engineered to sustain stable output under continuous operation, ensuring that heat dissipation, light decay, and component stress remain within controlled limits over time.

This approach ensures that every luminaire leaving production is already optimized for its intended operating environment, rather than relying on field adjustments to compensate for design limitations.

System Level: Designing How Light Works in the Space

Beyond the individual fixture, Ceramiclite treats lighting as a system operating within a defined space.

Photometric calculations and layout simulations are carried out to ensure required illuminance levels, uniformity ratios, and glare limits are met under real installation conditions. Control compatibility, including dimming, scheduling and intelligent regulation is considered at the design stage, allowing lighting behavior to match operational routines instead of remaining static.

Energy efficiency is evaluated not only by fixture efficacy, but by how the entire system performs over time, balancing output stability, control strategy, and maintenance frequency to reduce long-term operating costs.

Project Level: Adapting Engineering to the Environment

At the project level, Ceramiclite translates system design into site-specific execution.

Different environments such as ports, livestock facilities, chemical plants, or sports venues impose very different constraints related to corrosion, temperature, cleaning methods, and operating schedules. Fixtures, optics, controls, and installation methods are adjusted accordingly. Performance assumptions are verified against site conditions, and deployment support is provided to ensure correct installation, aiming, and commissioning.

This reduces the gap between design intent and on-site performance.

In summary, Ceramiclite does not treat products, systems, and projects as separate stages. By engineering across all three levels, we ensure that ceramic LED technology delivers consistent, predictable performance once it is installed and put into operation.

Ceramic LED Lights for Multiple Applications

Across livestock, sports, and industrial applications, Ceramiclite applies the same ceramic-based engineering approach to deliver predictable, long-term LED lighting performance where conventional LED solutions often fail.

Livestock Barn Lighting

Livestock barns expose lighting to ammonia, humidity, dust, and frequent wash-downs. Ceramiclite LED barn lighting solution uses ceramic LED technology that resists chemical corrosion and maintains stable output under long operating hours. Professionally tuned spectra support animal growth, behavior, and circadian rhythms, while uniform, low-glare distribution reduces stress. In addition, intelligent dimming and lighting control enable gradual transitions and precise light management, improving animal welfare while reducing maintenance in hard-to-access facilities. The result is reliable lighting with fewer failures and reduced maintenance in hard-to-access facilities.

Sports Lighting

Ceramiclite sports lighting solution delivers sustained high-power illumination with minimal lumen depreciation under continuous operation. Precision optical systems ensure high uniformity and effective glare control for athletes, spectators, and cameras. Stable color temperature, high color consistency, and flicker-free performance meet broadcast-grade requirements for high-speed and ultra-slow-motion filming. Intelligent dimming and control enable flexible operation for training, competition, and televised events across professional and multi-purpose sports venues.

Industrial Lighting

Ceramiclite industrial LED high bay lighting is engineered for factories, warehouses, ports, and other high-bay environments with long operating hours and harsh conditions. Ceramic LED technology ensures stable lumen output and thermal reliability, while optimized optics provide uniform, glare-controlled illumination for large work areas. Rugged construction resists dust, moisture, and mechanical stress, and flicker-free operation with intelligent dimming support improves energy efficiency and operational flexibility over the full service life.

Sustained Reliability Across the Full Lifecycle

In industrial and infrastructure applications, ceramic LED lighting performance is judged over years of operation, not at the moment of installation. Ceramiclite therefore designs its LED lighting systems with full lifecycle performance in mind, from initial specification through long-term operation.

Technical Reliability: Designed Into the Core

Reliability begins at the light source itself. Ceramiclite's ceramic LED cores are engineered with ultra-low thermal resistance, allowing heat to be dissipated efficiently even under high power density. This directly supports stable lumen output at elevated ambient temperatures and reduces the rate of long-term degradation.

At the same time, fluorescent transparent ceramic LED materials provide inherent resistance to sulfur, ammonia, and corrosive chemicals, preventing the packaging failures, lumen loss, and color shift commonly observed in conventional LED solutions.

Engineering & Project Support: Reducing Risk Over Time

Reliability is not only a materials issue, but also an engineering and execution issue. Ceramiclite supports projects from the design stage through commissioning, helping ensure that lighting layouts, control strategies, and installation methods match real operating conditions. Where necessary, performance parameters can be adjusted after commissioning to better align with site usage patterns.

As operational requirements change over time, ongoing technical guidance helps maintain system performance without unnecessary replacement or redesign.

Lifecycle Value: Performance That Holds Up Economically

By combining durable materials with system-level and project-level engineering, Ceramiclite LED lighting solution achieve a lower Total Cost of Ownership.

Longer service life reduces replacement frequency, stable output reduces corrective maintenance, and system scalability allows future expansion without reworking the entire installation. For customers operating multiple sites, this consistency simplifies maintenance planning and standardization across deployments.

Ultimately, Ceramiclite's responsibility does not end when the lights are turned on. It extends throughout the entire service life of the system, ensuring that performance, reliability, and cost expectations remain aligned year after year.

Trust & Proof

Ceramiclite lighting systems are validated not by marketing claims, but by science, standards, and long-cycle field performance.

Verified by Engineering, Backed by Science

Ceramiclite's professional LED lighting solutions are not validated by claims or short-term testing, but by long-cycle engineering deployment and scientific rigor. Every technology we deliver is grounded in measurable performance, repeatable results, and real operating conditions.

Proven in Long-Term Field Operation

Ceramiclite products operate continuously across demanding environments, including:

Industrial manufacturing facilities

Agricultural and livestock operations

Institutional and infrastructure projects

These deployments provide real-world performance data on thermal stability, lumen maintenance, and environmental resistance — far beyond laboratory testing conditions.

Materials & Performance Validated by Standards

Our ceramic materials and LED systems are designed and tested in alignment with stringent international and industry standards.

Key performance metrics — including thermal resistance, luminous stability, and environmental durability — are verified through structured testing protocols, ensuring consistency, compliance, and engineering predictability.

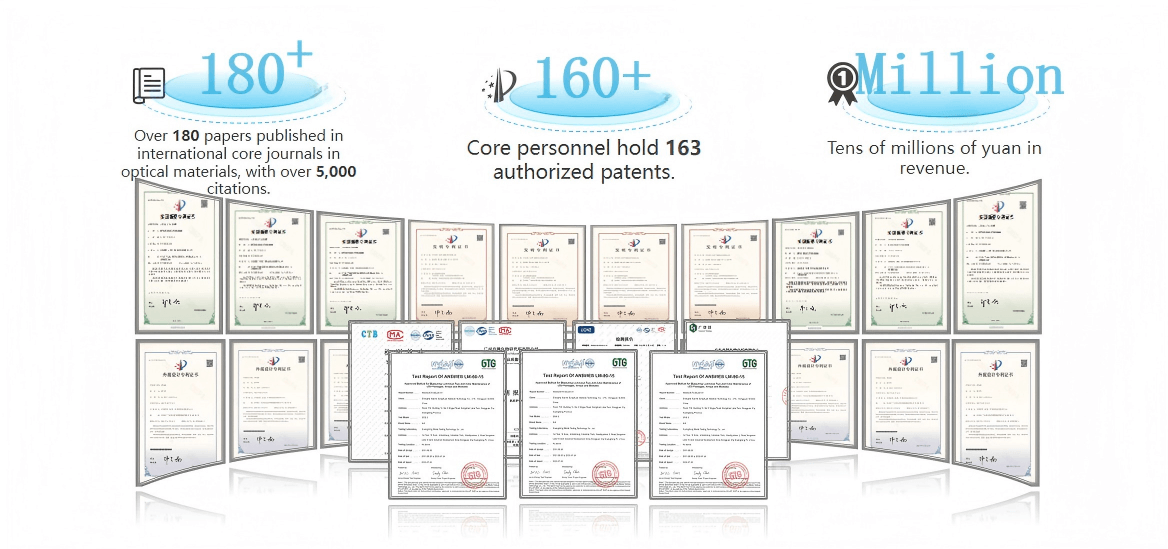

Scientific Foundation & R&D Depth

Ceramiclite's fluorescent transparent ceramic LED technology platform is built on deep scientific research:

Academic-level scientific advisors specializing in ceramic materials and optoelectronics

180+ peer-reviewed research publications

160+ granted and pending patents covering materials, LED packaging, and system-level innovation

This foundation enables continuous technological advancement not incremental product iteration.

Trusted by Engineering Partners

Ceramiclite collaborates closely with system integrators, engineering consultants, and project contractors to ensure seamless system integration and dependable performance.

Our approach supports consistent quality across installations and long-term confidence for multi-phase and repeat deployments.

What This Means for Our Customers

In demanding operating environments, Ceramiclite delivers lighting systems that behave predictably over time, not just at installation.

By addressing heat management, material degradation, and corrosion resistance at the core design level, common failure modes of conventional LEDs are significantly reduced. Lighting performance remains stable under continuous operation, even in high-temperature or chemically aggressive conditions.

This results in fewer unplanned maintenance interventions, longer service intervals, and more reliable long-term operation across single or multiple sites.

In short, Ceramiclite helps customers reduce operational risk and maintain consistent lighting performance throughout the system's lifecycle.

Product Series Recommendations:

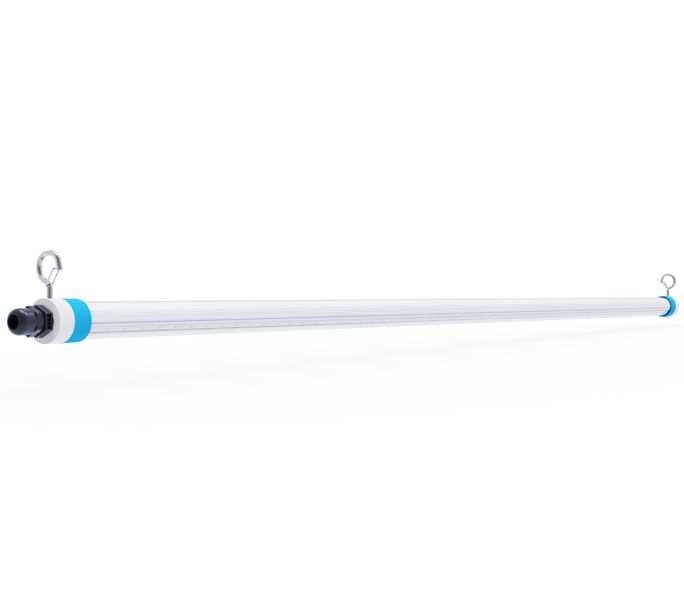

T8 LED Lights for Livestock Farms

_thumb.jpg)