Vollständiger Leitfaden zur Sportplatzbeleuchtung 2026

Inhaltsverzeichnis

Der Business Case: Warum jetzt upgraden?

Konformitätsbericht: IES- vs. EN-Normen

Hauptmerkmale von Hochleistungssystemen

Häufige Anwendungen und Benutzer

5 Schritte zur Auswahl des richtigen Herstellers

Fazit: Bereit für den Wechsel?

Einleitung

Die Verwaltung einer Sportanlage gleicht oft einem ständigen Kampf gegen steigende Energiekosten und flackernde Halogenmetalldampflampen. Jahrzehntelang hat die traditionelle Beleuchtung durch Ineffizienz und häufige, kostspielige Wartungszyklen die Betriebskosten stark belastet. Doch die technologische Landschaft hat sich gewandelt.

Bei der modernen Flutlichtbeleuchtung von Sportplätzen geht es nicht mehr nur um Sichtbarkeit; vielmehr geht es um die präzise Balance zwischen Energiemanagement, visueller Leistung und Umweltverträglichkeit .

Wenn Sie eine Modernisierung für 2026 planen, ist Raten keine Option. Egal, ob Sie ein Highschool-Stadion in den USA oder einen Sportplatz in Europa verwalten – dieser Leitfaden dient Ihnen als technische Blaupause.

Im Folgenden erläutern wir die entscheidenden Unterschiede zwischen den IES- und EN-Konformitätsstandards, liefern Ihnen praxisrelevante Marktdaten und zeigen Ihnen genau, wie Sie den ROI des Umstiegs auf LED berechnen können – damit Ihr Projekt sowohl sicher als auch profitabel ist.

Der Business Case: Warum jetzt upgraden?

Die Entscheidung für eine Modernisierung der Beleuchtung in Ihren Räumlichkeiten ist selten allein eine Frage der Ästhetik; sie ist eine finanzielle Notwendigkeit. Bis 2026 hat sich die Kluft zwischen veralteter Technologie und modernen Lösungen deutlich vergrößert, sodass ein abwartendes Vorgehen ein kostspieliger Fehler sein kann.

Drastische Energiekostenreduzierung:

Der unmittelbarste Effekt der Umstellung auf LED-Sportplatzbeleuchtung zeigt sich in Ihren Kosten. Anlagen, die von HID-Lampen (Hochdruckentladungslampen) auf LED umrüsten, verzeichnen typischerweise Energieeinsparungen von 50 % bis 75 % . Für einen Standard-Fußballplatz oder eine Tennisanlage, die jährlich Hunderte von Stunden genutzt wird, bedeutet diese Effizienz eine jährliche Ersparnis von Tausenden von Euro.

Schluss mit dem Wartungsaufwand!

Wartung ist der heimliche Kostenfresser. Herkömmliche Metallhalogenlampen verschleißen schnell, verlieren deutlich an Lichtstrom und müssen etwa alle 10.000 Betriebsstunden ausgetauscht werden. Hochwertige LED-Systeme hingegen – insbesondere solche mit fortschrittlicher Keramik-Wärmeableitungstechnologie – sind auf eine Lebensdauer von über 50.000 Stunden ausgelegt . Diese Langlebigkeit eliminiert praktisch die wiederkehrenden Kosten für Ersatzlampen und teure Hubarbeitsbühnen.

Betriebliche Flexibilität: Sofortiges Ein-/Ausschalten.

Herkömmliche Systeme schränken Ihren Zeitplan durch 15-minütige Aufwärm- und Abkühlzeiten ein. Moderne LED-Lösungen bieten hingegen die Möglichkeit des sofortigen Ein-/Ausschaltens . Dadurch können Facility Manager die Feldnutzung optimieren und das Feld für Veranstaltungen sofort beleuchten oder aus Sicherheitsgründen abdunkeln – ohne unnötige Wartezeiten und damit verbundene Energieverschwendung.

Konformitätsbericht: IES- vs. EN-Normen

Die Installation von Flutlichtanlagen auf Sportplätzen ohne Berücksichtigung der geltenden Normen birgt Haftungsrisiken. Ob es sich um die Modernisierung eines lokalen Schulspielfelds oder eines Profistadions handelt – die Beleuchtungsstärke muss bestimmten Kriterien entsprechen, um die Sicherheit der Spieler und die Sichtbarkeit der Zuschauer zu gewährleisten.

In den Vereinigten Staaten setzt die Illuminating Engineering Society (IES) mit der Norm RP-6-20 den Maßstab . In Europa regelt die EN 12193 die Sicherheitsstandards . Obwohl beide ähnliche Sicherheitsziele verfolgen, unterscheiden sich die Kriterien und Klassifizierungen geringfügig. Zu verstehen, in welche dieser „Klassen“ Ihre Anlage einzuordnen ist, ist der erste Schritt, um eine Überdimensionierung (und damit Budgetverschwendung) oder Unterdimensionierung (und damit verbundene Gefahren) Ihres Projekts zu vermeiden.

Anhand der untenstehenden Vergleichsmatrix können Sie die Anforderungen für Ihre spezifische Region und Ihren Standort ermitteln:

Merkmale | USA (IES RP-6-20) | Europa (EN 12193) | Einblick |

Messung | Foot-Candles (fc) | Lux (lx) | 1 fc ≈ 10,76 lx |

Klasse I (Pro) | > 75 - 100 fc | > 750 lx | Erforderlich für Fernsehübertragungen und große Zuschauermengen |

Klasse II (College) | 50 fc | > 500 lx | Wichtig für die Wettkampfsicherheit und das College-Spiel |

Klasse III (HS/Verein) | 30 fc | > 200 lx | Der Standard für Wettkämpfe und Training an Gymnasien |

Gleichmäßigkeit (Min./Durchschnitt) | Verhältnis 0,5 | Verhältnis 0,5 - 0,7 | Verhindert gefährliche "Zebrastreifen" oder Schatten auf dem Spielfeld |

Blendung (GR) | < 50 | < 50 | Entscheidend für den Komfort des Spielers und die visuelle Verfolgung des Balls |

Globaler Markteinblick : Während sich US-amerikanische und EU-Standards stark auf Lichtstärke und Blendung konzentrieren, rücken in Südostasien hohe IP-Schutzarten und Korrosionsbeständigkeit zunehmend in den Vordergrund . Aufgrund der hohen Luftfeuchtigkeit und der intensiven Hitze in diesen Regionen fordern Gebäudemanager strengere Berechnungen zur Energieeffizienz (ROI) und einen über die Standard-Schutzart IP65 hinausgehenden Witterungsschutz.

Hauptmerkmale von Hochleistungssystemen

Bei der Bewertung von Angeboten für die Beleuchtung von Sportplätzen ist es entscheidend, über die reine Wattzahl und Lumenanzahl hinauszublicken. Obwohl die Standard-LED-Technologie derzeit den Markt dominiert, bringen Hochleistungsanwendungen im Sportbereich diese konventionellen Leuchten oft an ihre Grenzen. Die intensive Hitzeentwicklung von Leuchten mit über 500 W kann die Standardmaterialien beschädigen.

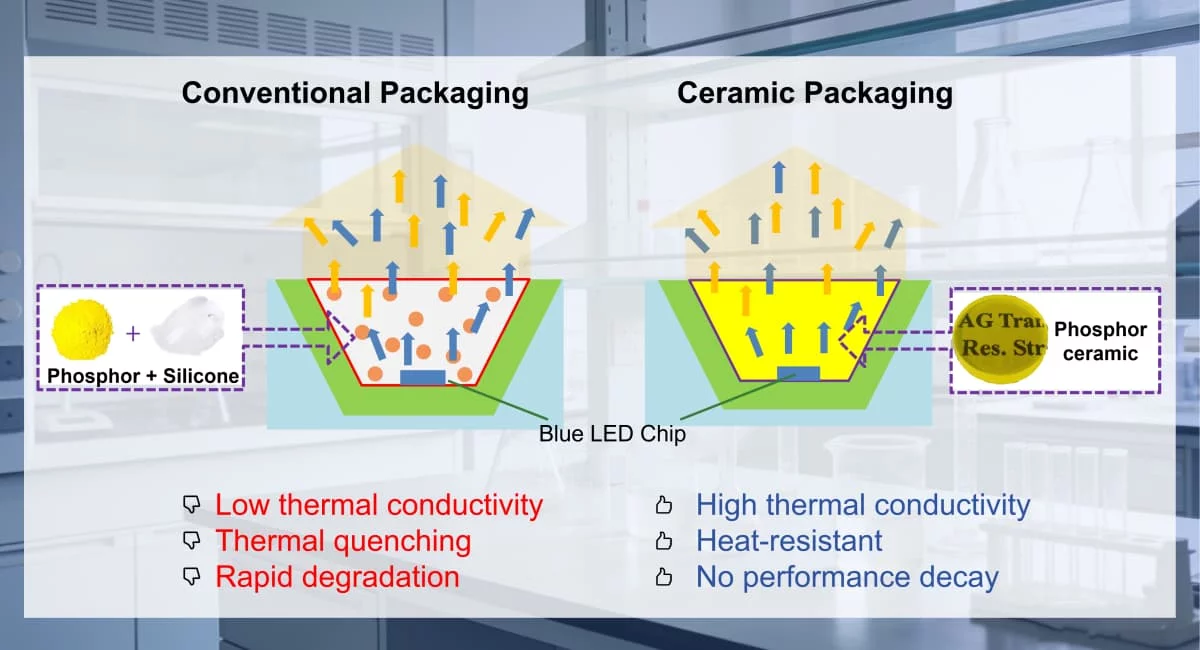

Um eine Lebensdauer von mindestens 10 Jahren zu gewährleisten, setzen Facility Manager nun auf die fortschrittliche Keramik-LED-Technologie.Im Gegensatz zu herkömmlichen LEDs, die auf organischen Materialien basieren (die altern und zerfallen), nutzen moderne Systeme fluoreszierende transparente Keramik (FTC), um auch rauen Umgebungsbedingungen standzuhalten.

Hier ein Vergleich der marktüblichen Technologie mit dem Hochleistungskeramikstandard:

Merkmale | Standard-LED-Technologie | Fortschrittliche Keramik-LED (FTC) | Warum ist das wichtig? |

Verkapselungsmaterial | Silikon / Epoxidharz. (Organisch) | Fluoreszierende transparente Keramik. (Anorganisch) | Silikon vergilbt mit der Zeit durch Hitze und reißt, wodurch die Lichtausbeute abnimmt. Keramik hingegen altert nicht und garantiert dauerhafte Klarheit. |

Wärmemanagement | Aluminium-Leiterplatte. | Keramikkörper / Eutektische Verbindung | Aluminium ist anfällig für Korrosion und thermische Engpässe. Keramik bietet eine überlegene Wärmeableitung und ist chemisch stabil. |

Korrosionsbeständigkeit | Mäßig (abhängig von der Beschichtung). | Hoch (Naturmaterial). | Besonders wichtig für Küstenregionen oder feuchte Gebiete. Keramik ist von Natur aus unempfindlich gegenüber Salz, Feuchtigkeit und Säuren. |

Lumenerhaltung | Nimmt nach 10.000 Stunden deutlich ab. | Extrem geringer Lichtstromabfall | Die FTC-Technologie verhindert den „Bräunungseffekt“ und erhält die nahezu ursprüngliche Helligkeit über 50.000 Stunden hinweg. |

Der „FTC“-Vorteil: Lösung des Hitzeproblems.

Die Schwachstelle herkömmlicher Hochleistungs-LEDs ist der Silikonkleber, der den Leuchtstoff bindet. Unter der intensiven Hitze von Flutlichtanlagen auf Sportplätzen dunkelt dieses Silikon nach (verkohlt), blockiert das Licht und verändert die Farbtemperatur.

Ceramiclite löst dieses Problem, indem das Silikon durch fluoreszierende transparente Keramik (FTC) ersetzt wird . Dabei handelt es sich um eine massive, anorganische Phosphorkeramikplatte. Sie ist unempfindlich gegenüber Hitze, Feuchtigkeit und chemischer Korrosion.

Durch die Verwendung dieses Materials in Luft- und Raumfahrtqualität erreicht das Beleuchtungssystem eine Haltbarkeit und thermische Stabilität, die mit herkömmlichen, kunststoffgekapselten LEDs einfach nicht zu erreichen ist.

Häufige Anwendungen und Benutzer

Hochwertige Flutlichtanlagen für Sportplätze sind keine Einheitslösung. Unterschiedliche Anlagen stehen vor individuellen Herausforderungen, von strengen Gesetzen gegen Lichtverschmutzung in Wohngebieten bis hin zu Anforderungen an hochauflösende Fernsehübertragungen. Unsere Lösungen sind speziell auf die Bedürfnisse folgender Branchen zugeschnitten:

Schulen und Universitäten : Diese Einrichtungen arbeiten oft mit knappen öffentlichen Budgets. Priorität hat hier die Balance zwischen Kosteneffizienz, Schülersicherheit und Langlebigkeit, um sicherzustellen, dass die Beleuchtung jahrzehntelang hält, ohne das Wartungspersonal zu überlasten.

Städtische Parks und Freizeiteinrichtungen : Planer in städtischen Gebieten legen großen Wert auf die Einhaltung der „Dark Sky“-Richtlinien . Ziel ist es, das Spielfeld hell auszuleuchten und gleichzeitig sicherzustellen, dass kein Licht in angrenzende Wohngärten oder Straßen dringt.

Professionelle Stadien : Für Fernsehübertragungen muss die Beleuchtung flimmerfrei sein , um Zeitlupenwiederholungen zu ermöglichen. Hoher Farbwiedergabeindex (CRI) und gleichmäßige Ausleuchtung sind für die Übertragungsqualität unerlässlich.

Kommerzielle Sportkomplexe : Für private Akademien und Mietplätze steht die Rentabilität im Vordergrund . Aufgrund der langen Betriebszeiten jede Nacht benötigen diese Unternehmen einen extrem niedrigen Energieverbrauch, um ihre Gewinnmargen zu maximieren.

5 Schritte zur Auswahl des richtigen Herstellers

Die Wahl eines Beleuchtungspartners ist eine zehnjährige Verpflichtung. Um kostspielige Nachrüstungen oder Verstöße gegen die Vorschriften zu vermeiden, nutzen Sie diese Checkliste zur Überprüfung potenzieller Lieferanten.

1. Verlangen Sie einen kostenlosen Lichtmessplan (unverhandelbar).

Kaufen Sie Leuchten niemals nur nach Wattzahl. Ein professioneller Anbieter muss Ihnen eine computergestützte Lichtmessstudie (z. B. mit AGi32) erstellen, die auf die spezifischen Abmessungen Ihres Einsatzbereichs zugeschnitten ist . Dieser Plan beweist, dass die Konstruktion die IES/EN-Normen für Lichtstärke und Gleichmäßigkeit erfüllt, bevor Sie auch nur einen Cent ausgeben. Wenn Ihnen dieser Plan nicht angeboten wird, sollten Sie sich nach einem anderen Anbieter umsehen.

2. Überprüfen Sie die Wärmeableitungstechnologie.

Hitze ist die Hauptursache für LED-Ausfälle. Bei Hochleistungsanwendungen (500 W+) können herkömmliche Aluminium-Kühlkörper sich mit Wärme sättigen und korrosionsanfällig werden. Achten Sie auf Hersteller, die moderne Keramiktechnologie einsetzen . Da Keramik nichtleitend und chemisch stabil ist, bewältigt sie thermische Belastungen deutlich besser als Aluminium und gewährleistet so, dass die Lichtleistung in den ersten Jahren nicht rapide abnimmt.

3. Prüfen Sie die erforderlichen Zertifizierungen.

Stellen Sie sicher, dass die Leuchten die für Ihre Region geltenden Prüfzeichen tragen. In den USA benötigen Sie UL (Sicherheit) und DLC Premium (erforderlich für staatliche Förderprogramme). In Europa und Südostasien sind CE und RoHS obligatorisch. Diese Zertifizierungen bestätigen die Sicherheits- und Effizienzangaben des Produkts.

4. Garantiebedingungen prüfen:

Lesen Sie das Kleingedruckte. Deckt die Garantie die gesamte Leuchte oder nur die LED-Chips ab? Eine seriöse Garantie (üblicherweise 5–10 Jahre) sollte Treiber, Gehäuse und Leuchtmittel abdecken. Vorsicht vor Garantien, die Arbeitskosten oder Versandkosten für Ersatzteile ausschließen.

5. Kompatibilität mit Steuerungssystemen sicherstellen:

Moderne Sportbeleuchtung sollte „smart“ sein. Prüfen Sie, ob die Leuchten mit gängigen Steuerungsprotokollen wie DALI, Zigbee oder 0-10V-Dimmung kompatibel sind . So können Sie die Beleuchtung in ein zentrales Gebäudemanagementsystem integrieren und Funktionen wie Zoneneinteilung, Zeitplanung und stufenloses Dimmen nutzen.

Häufig gestellte Fragen (FAQ)

Hier sind die häufigsten Fragen, die Facility Manager bei der Modernisierung ihrer Sportplatzbeleuchtung stellen.

F: Wie viele Lumen benötige ich für ein Standard-Fußballfeld?

A: Darauf gibt es keine pauschale Antwort – es hängt ganz von der Spielklasse ab. Für ein Highschool-Feld der Klasse III, das 30–50 Foot-Candles (fc) benötigt, sind typischerweise 400.000 bis 600.000 Lumen erforderlich . Die Platzierung ist jedoch wichtiger als die reine Lichtstärke; ein photometrischer Plan ist notwendig, um sicherzustellen, dass die Lumen das Spielfeld gleichmäßig erreichen.

F: Was kostet die Installation einer Flutlichtanlage für Sportplätze?

A: Eine komplette Modernisierung kostet in der Regel zwischen 40.000 und 100.000 US-Dollar , je nachdem, ob nur die Leuchten oder auch die Masten ausgetauscht werden. Die anfänglichen Kosten sind zwar hoch, aber der Umstieg auf LED-Beleuchtung macht Vorschaltgeräte und Lampenwechsel überflüssig und amortisiert sich oft innerhalb von 3–5 Jahren durch Wartungs- und Energieeinsparungen.

F: Kann ich bestehende Masten mit neuen LED-Leuchten nachrüsten?

A: Im Allgemeinen ja. Moderne LED-Leuchten sind oft leichter und haben ein kleineres Windprofil (EPA) als alte Metallhalogenidlampen. Sie müssen jedoch eine statische Windlastberechnung durchführen, um sicherzustellen, dass die bestehenden Masten die neue Installation sicher tragen können, insbesondere in windreichen Gebieten.

F: Welche Farbtemperatur ist für Sportbeleuchtung optimal?

A: Der Branchenstandard liegt bei 5000 K bis 5700 K. Dieses tageslichtweiße Licht bietet den besten Kontrast, damit Spieler auch bei hohen Geschwindigkeiten Bälle gut verfolgen können und die Athleten konzentriert bleiben. Es ist auch der bevorzugte Standard für Übertragungskameras.

F: Wie kann ich Lichtverschmutzung in Wohngebieten verhindern?

A: Der Schlüssel liegt in der optischen Steuerung. Hochwertige Leuchten verwenden asymmetrische Linsen und externe Blenden, um das Licht gezielt auf das Spielfeld zu lenken. Dadurch wird die Lichtverschmutzung minimiert und verhindert, dass Licht in benachbarte Fenster dringt. So entspricht Ihre Anlage den örtlichen Lichtschutzbestimmungen.

Fazit: Bereit für den Wechsel?

Die Modernisierung Ihrer Anlage ist eine bedeutende Investition, doch die Datenlage ist eindeutig: Der Umstieg auf LED bietet durch Energieeinsparungen und geringeren Wartungsaufwand eine unschlagbare Rendite. Allerdings reicht es nicht, einfach nur helle Leuchten zu kaufen. Sie benötigen ein System, das den Witterungseinflüssen standhält, die IES/EN-Normen erfüllt und dank fortschrittlicher Keramiktechnologie vor thermischer Zersetzung schützt.

Hören Sie auf zu schätzen und beginnen Sie mit präziser Planung.

Verlassen Sie sich nicht auf Ihr Layout. Kontaktieren Sie Ceramiclite noch heute für eine kostenlose photometrische Studie und erfahren Sie genau, wie viel Sie bei Ihrem nächsten Projekt sparen können.

_thumb.jpg)